Chapter: Civil : Design of Reinforced Concrete Elements : Limit State Design For Bond, Anchorage Shear and Torsion

Design Problem, Important Question And Answer: Civil - Limit State Design For Bond, Anchorage Shear and Torsion

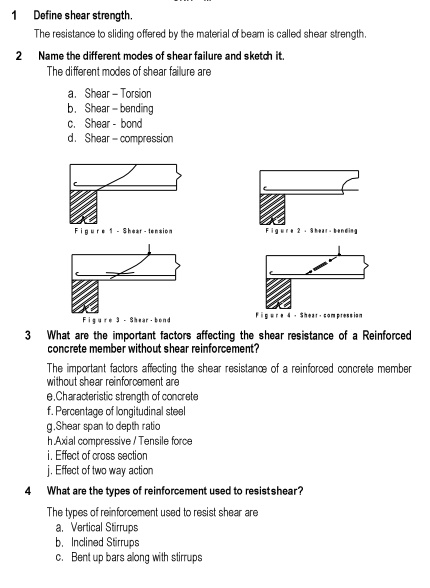

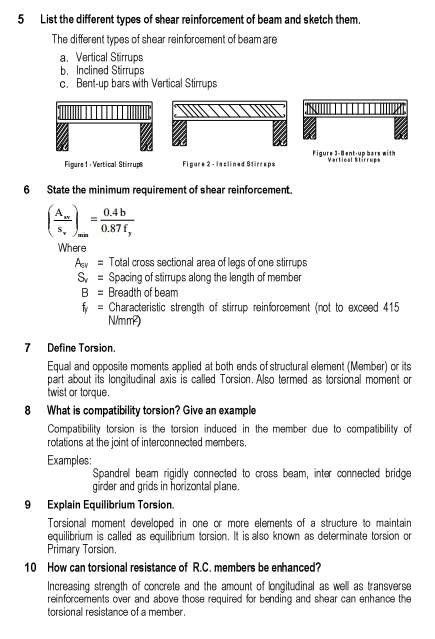

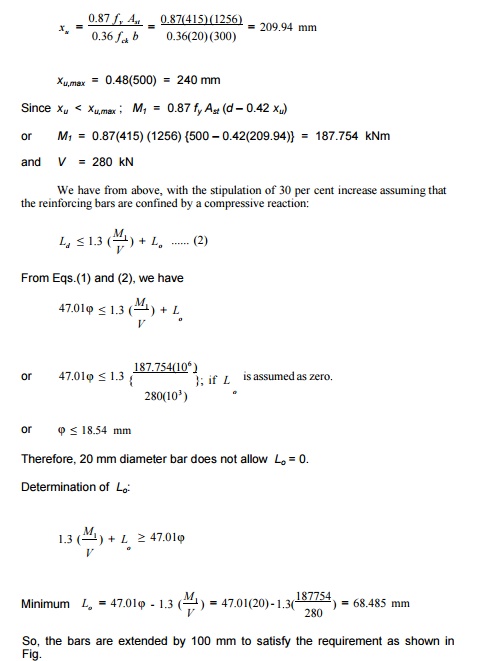

Problem :

Determine the anchorage length of 4-20T

reinforcing bars going into the support of the simply supported beam shown in

Fig. 6.15.5. The factored shear force Vu = 280 kN,

width of the column support = 300 mm. Use M 20 concrete and Fe 415 steel.

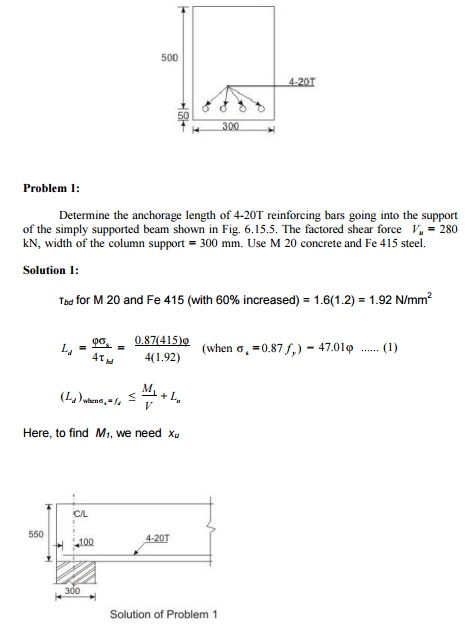

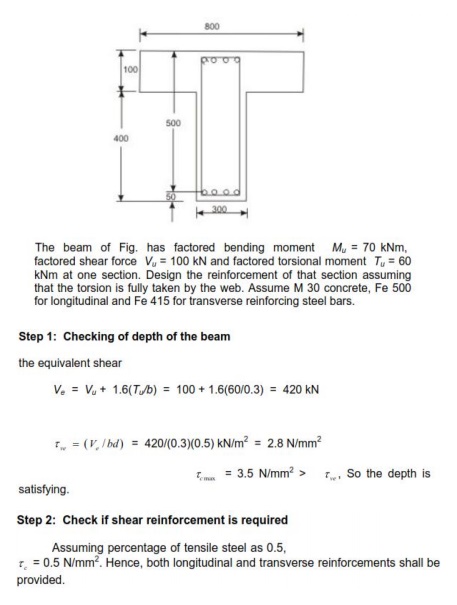

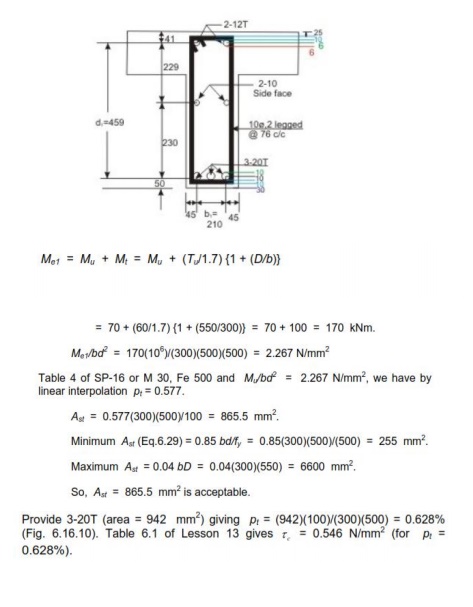

DESIGN FOR TORSION

INTRODUCTION

Torsion when

encountered in reinforced concrete members usually occurs in combination with

flexure shear. Torsion in its associated„pure?with metalformshafts)

is(generallyrarelyencounteredinreinforced concrete.

The interactive

behavior of torsion with bending moment and flexural shear in reinforced

concrete beams is fairly complex, owing to the no homogeneous, nonlinear and

composite nature of the material and the presence of cracks. For convenience in

design, codes prescribe highly simplified design procedures, which reflect a

judicious blend of theoretical considerations and experimental results.

These design procedures

and their bases are described in this chapter, following a brief review of the

general behavior of reinforced concrete beams under torsion.

EQUILIBRIUM

TORSION AND COMPATIBILITY TORSION

Torsion may be induced in a reinforced concrete

member in various ways during the process of load transfer in

a structural system. In

reinforced concrete desi commonly used to refer to two different torsion

-inducing situations.

In „equilibrium torsion?,ducedbyaneccentric

loading,theandtorsionequilibriumconditionsisaloneinsuffice

in determining the

twisting moments. In „compati angle of twist and the resulting twisting moment

depends on the torsional stiffness of the member.

In some (relatively rare) situations, axial force

(tension or compression) may also be involved.

It must be clearly

understood that this is merely a matter of terminology, and that it does not

imply for instance, equilibrium conditions need not be satisfied in cases of

There are some

situations (such as circular beams supported on multiple columns) where both

equilibrium torsion and compatibility torsion coexist.

EQUILIBRIUM TORSION

This

is associated with twisting moments that are developed in a structural member

is maintain static equilibrium with the external loads, and are independent of

the torsional stiffness of the member. Such torsion must be necessarily

considered design. The magnitude of the twisting moment does not depend on the

torsional stiffness of the member, and is entirely determinable from statics

alone. The member has to be designed for the full torsion, which is transmitted

by the member to the supports. More ever, the end(s) of the member should be suitably

restrained to enable the member to resist effectively the torsion induced.

Typically, equilibrium torsion is induced in beams supporting lateral over

hanging projections, and is caused by the eccentricity in the loading (Figure).

Such torsion is also induced in beams curved plan and subjected to gravity

loads, and in beams where the transverse loads are eccentric with respect to

the shear centre of the cross -section.

Compatibility

Torsion

This

is the name given to the type of torsion induced in a member rotations (twists)

applied at one or more points along the length of the member. It twisting

moments induced are directly dependent on the torsional stiffness of the

member. These moments are generally statically in determine and their analysis

necessarily involves (rotational) compatibility in the floor beam system has

shown in figure,Bat th the end B. As the primary (Spandrel) beam ABC is

monolithically connected with the secondary beam BD at the joint B.,

compatibilityB inatthespandrelBimpliesbeamABC,and a bendinganangl moment will

develop at the end b of beam BD. The bending moment will be equal to, and will

act in a direction opposite to the twisting moment, in orderBandthetwistingto/

sat bending moment at b depends on the torsional stiffness of beam ABC and the

flexural stiffness of beam BD.

The torsional stiffness

of a reinforced concrete member is drastically reduced by torsional cracking.

This results in a very large increase in the angle of twist, induced twisting

moment. For this reasons, the code (CL.40.1) permits the designer to neglect

the torsional

stiffness of reinforced

concrete members at the structural analysis stage itself, so that the need for

detailed design for torsion in such cases does not arise at the design stage.

With reference to figure, this implies assuming a fictitious hinge (i.e., no

rotational restraint) at the end B of the beam BD, and assuming a continuous

support (spring, support, actually)at the joint D. Incidentally, this

assumption helps in reducing the degree of static indeterminacy of the

structure (typically, a grid floor), thereby simplifying the problem of

structural analysis. Thus, the code states:

In general, where the

torsional resistance or stiffness of members has not been taken into account in

the analysis of a structure no specific calculations for torsion will be

necessary [CL40.1 of the code].

Of course, this

simplification implies the acceptance of cracking and increased deformations in

the torsional member. It also means that during the first time loading, a

twisting moment up to the cracking torque of the the member, prior to torsional

cracking. In order to control the subsequent cracking and to impart ductility

to the member, it is desirable to provide a minimum torsional reinforcement,

equal to that required

to resist the „cracking t reinforcement specified by the code (CL. 25.5.1.6) is

to ensure some degree of control of torsional cracking of

beams due to compatibility torsion.

If, however, the designer chooses to consider „ that

a realistic estimate of torsional stiffness is made for the purpose of

structural analysis, and the required

Related Topics