Chapter: Civil : Design Of Reinforced Concrete And Brick Masonry Structures- Design Of Flat Slab

Design Of Flat Slab

DESIGN

OF FLAT SLAB

a) Interior

panel

b) Exterior

panel

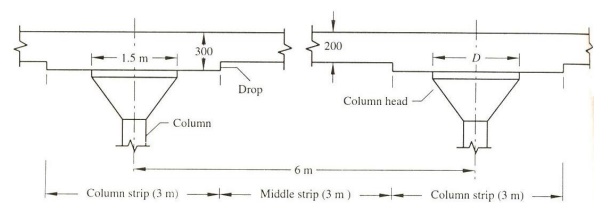

Various components of flat slab:

i)

Without drop and head

ii)

With drop and without head

iii)

With drop and head

Column strip : It is the

design strip having a width of l2/4, where l2 is the span

transverse to l1. l2 -longer span, moment is considered

along the span l1

Middle strip : It is the design strip bounded by a column

strip on its opposite sides

Proportioning of flat slabs:

As per cl.31 of IS456-2000,

the span by depth ratio of two way slab is applicable for flat slabs and the

values can be (l/d)modified by 0.9 for flat slabs with drops.

Take à l/d

as 32 for HYSD bars

As per ACI -The drop

thickness should not be less than 100mm or (Thickness of slab)/4. While

calculating span by depth ratio, longer span is used.

The thickness of slab should not be less than 125mm.

The purpose of column drop

is to reduce the shear stress and also reduce the reinforcement in the column

strip.

The increase in column

diameter at the head flaring of column head takes care of punching shear

developed at a distance of d/2 all around the junction between the slab and

column head.

Two methods of design are available for flat slabs:

1. Direct

design method

2. Equivalent

frame method

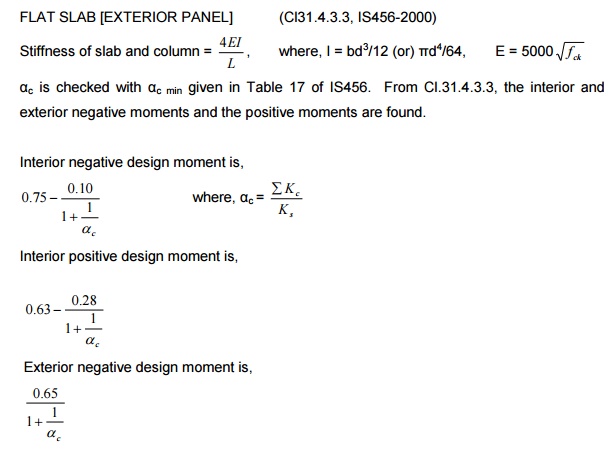

Direct design method: (Cl.31.4.1, IS456-2000)

Requirements for direct design methods are,

1. There

must be atleast three continuous spans in each direction

The panels should be rectangular with ly/lx =

l2/l1 ratio < 2

3. The

columns must not offset by more than 10% of the span from either of the

successive columns

4. Successive

span length in each direction must not differ by more than one third of longer

span.

5. Design

live load must not exceed 3 times the designed dead load

Design

procedure:

As per Cl.31.4.2.2, IS456-2000, the total moment for a

span bounded by columns laterally is Mo = Wlo/2, where Mo

is the sum of positive and negative moment in each direction. W is the total

design load covered on an area L2L1

W =

w x L2 x Ln

This

moment is distributed for the column strip and middle strip

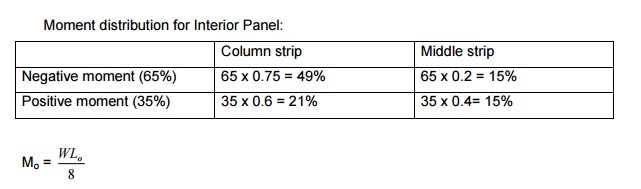

Moment

distribution for Interior Panel:

Also

Lo should not be less than 0.65 times of L1 [Ln

> 0.65L1)

1) Design a flat slab system (interior panel) to suit the

following data: Size of the floor = 20 x 30m

Column interval = 5m c/c Live load on slab = 5kN/m2

Materials used are Fe415 HYSD bars and M20

concrete

Proportioning of flat slab:

Assume l/d as 32, è d =

5000/32 è d = 156.25mm

d = 175mm (assume), D = 175 + 20 + 10/2 = 200mm

As per ACI code, the thickness

of drop > 100mm and > (Thickness of slab)/4 Therefore, 100mm or

200/4=50mm

Provide a column drop of 100mm

Overall depth of slab at

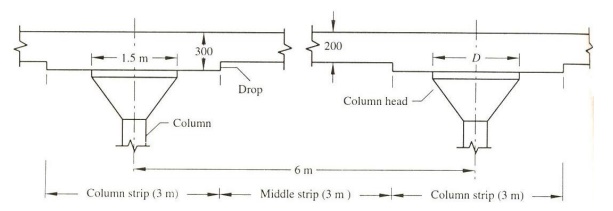

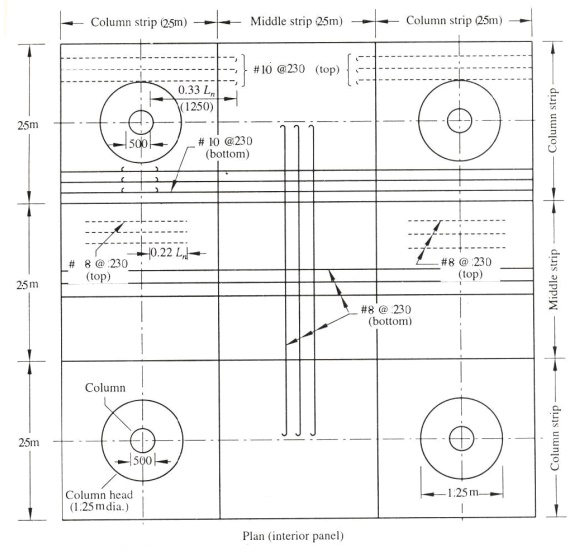

drop = 200 + 100 = 300mm Length of the drop > L/3 = 5/3 = 1.67m

Provide length of drop as

2.5m. For the panel, 1.25m is the contribution of drop. Column head = L/4 = 5/4

= 1.25m

L1 = L2 = 5m

Ln = L2 -D = 5 -1.25 = 3.75m

As per code, Mo = WLo/8

Loading on slab: (Average thickness = (300 + 200)/2 =

250mm)

Self weight of slab = 25 x 0.25 =

6.25 kN/m2

Live load = 5 kN/m2

Floor finish = 0.75 kN/m2

Total = 12 kN/m2

Factored load = 1.5 x 12 = 18 kN/m2

W = wu x L2 x Ln = 18 x

5 x 3.75 = 337.5 kN

Total moment on slab panel = (337.5 x

3.75)/8 = 158.203 kNm

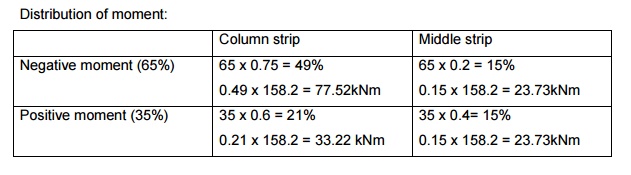

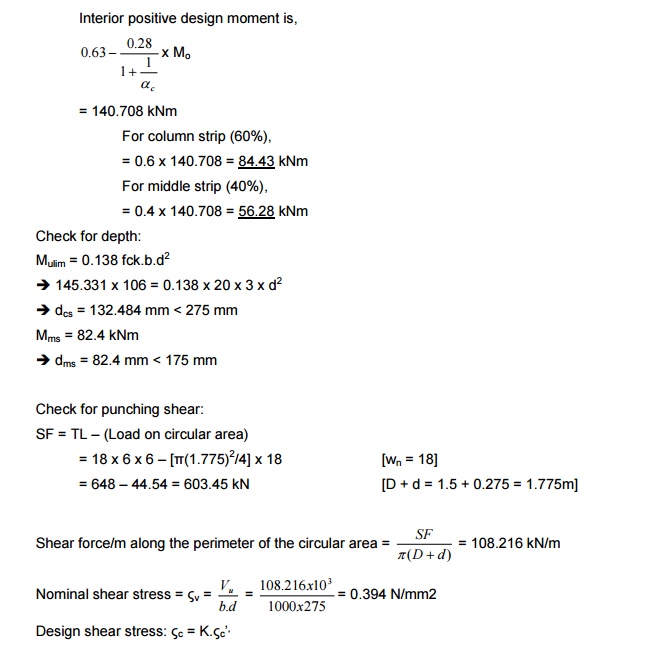

Distribution of moment:

Check for depth adopted:

Column strip:

Mu = 0.138.fck.b.d2

b = 2.5m

77.5 x 106 = 0.138 x 20 x 2.5 x 1000 x d2

d = 105.98mm ~ 106mm < 275mm Middle strip:

Mu = 0.138.fck.b.d2 b = 2.5m

23.73 x 106 = 0.138 x 20 x 2.5 x 1000 x d2

d = 58.68mm ~ 59mm < 175mm

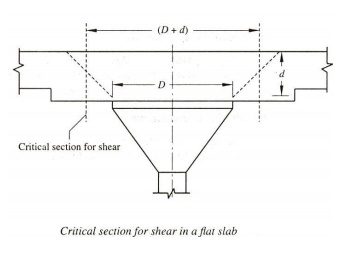

Check for punching shear:

The slab is checked for punching shear at a distance of

d/2 all around the face of the column head. The load on the slab panel

excluding the circular area of diameter (D + d) is the punching shear force.

Shear force = Total Load -(Load on circular area)

= 18 x

5 x 5 -(?(D 2/4)+x wd)n

= 417.12

kN

Shear force along the perimeter of the circular area = ShearForce

/ p(D +d ) = 87.06 kN

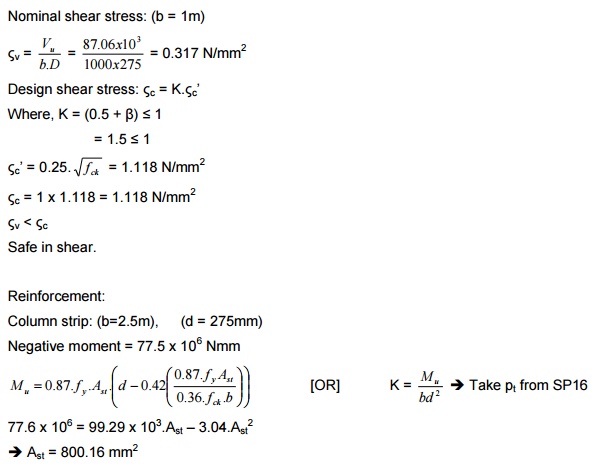

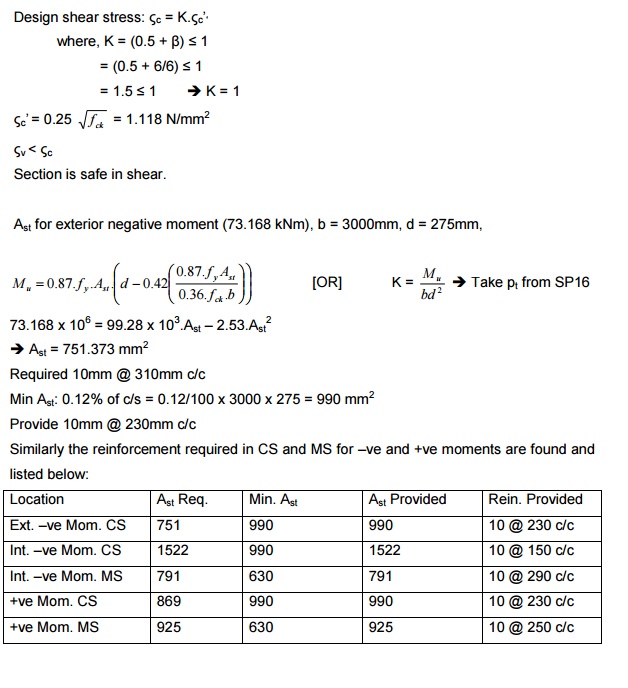

Nominal shear stress: (b = 1m)

Required 10mm @ 240mm c/c

Min Ast: 0.12% of c/s = 0.12/100 x 1000 x 275

= 825 mm2

Provide 10mm @ 230mm c/c

Positive moment = 33.2 kNm

Ast = 337.876 mm2

Provide 8mm @ 370mm c/c

Min. steel: Provide 10mm @ 230mm c/c

Middle strip: (b = 2.5m), (d = 175mm)

Negative and positive

moment: 23.7 kNm Ast = 382.6 mm2

Ast min. = (0.12/100 x 1000 x 2500 x 175) =

525 mm2

Provide 8mm @ 230mm c/c.

The distribution of interior

negative moment for column strip and middle strip is in the ratio 3:1 (0.75 :

0.25)

The exterior negative moment

is fully taken by the column strip. The distribution of positive moment in

column strip and middle strip is in the ratio 1.5 : 1 (0.6 : 0.4).

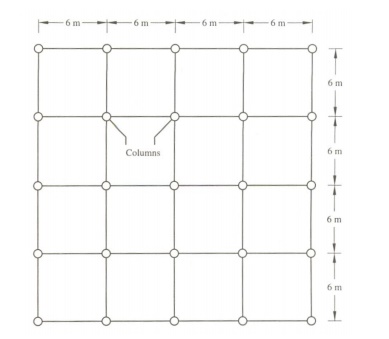

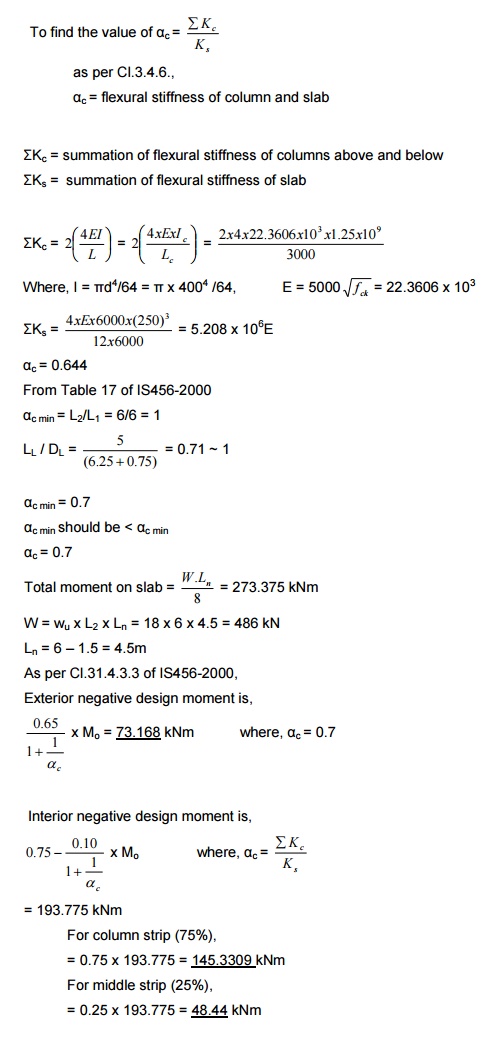

Design an exterior panel of a flat slab floor system of size

24m x 24m, divided into panels 6m x 6m size. The live load on the slab is 5

kN/m2 and the columns at top and bottom are at diameter 400mm.

Height of each storey is 3m. Use M20 concrete and Fe415 steel.

l/d = 32 è d = 6000/32 = 187.5 mm

Length of drop ? 3m

Length of drop = Column strip = 3m

Assume effective depth, d =

175mm, D = 200mm As per ACI, Assume a drop of 100mm

Depth of slab at the drop is 300mm Diameter of column

head = l/4 = 6/4 = 1.5m

Loading on slab:

Self weight of slab = (0.2 + 0.3)/2 x 25 = 0.25 x 25 = 6.25 kN/m2

Live load = 5 kN/m2

Floor finish = 0.75 kN/m2

Total = 12 kN/m2

Factored load = 1.5 x 12 = 18 kN/m2

Related Topics