Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Product Design and CAD/CAM in the Production System

CAD System Hardware

CAD SYSTEM

HARDWARE

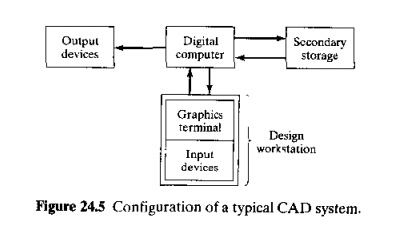

The

hardware for a typical CAD system consists of the following

components: (1) one or more design workstations, (2) digital computer, (3)

plotters, printers. and other output devices. and (4) storage devices. The

relationship among the components i, illustrated in Figure 24.S.ln addition,

the CAD system would have a communication interface to permit transmission of

data to and from other computer systems. thus enabling some of the benefits of

computer integration

Design

Workstations. The workstation is the interface between computer

and

user in the

CAD system. Its functions are the following: (1) communicate with the CPU. (2) continuously generate

a graphic image. (3) provide

digital descriptions of the image, (5) translate user commands

into operating functions, and (5) facilitate interaction between the user and

the system.

The

design of the CAD workstation and its available features have an important

influence on the convenience, productivity. and quality of the user's output.

The workstation must include a graphics display terminal and a set of user

input devices. The display terminal must be capable of showing both graphic~

and alphanumeric text. It is the principal means by which the system

communicates with the user. For optimum graphics display, the monitor

should have a large color screen with high resolution.

The user

input devices permit the operator to communicate with the system. To operate

the CAD system,

the user must be able to accomplish the following: (1) enter alphanumeric data,

(2) enter commends to the system (0 perform

various graphics operations, and (3) control the cursor position on the display

screen. To enter alphanumeric data, an alphanumeric keyboard is provided. A

conventional type writer like keyboard allows the designer to input numerical

and alphabetic characters into the system. The alphanumeric

keyboard

can also be used to enter commands and instructions to the system. However.

other input devices accomplish this function more conveniently. Special function keypads have been developed to

allow entry of a command in only one or two keystrokes. These special keypads

have from 10 to 50 function keys, depending on the system. However, each key

provides more than one function, depending on the combination of keys pressed

or which software is being used. Another input device for entering commands to

a CAD system is the electronic tablet,

an electronically sensitive board on which an instruction set is displayed,

arid commands arc entered using a puck or electronic pen.

Cursor control

permits the operator to position the cursor on the screen to identify a

location where some function is to be executed. For example, to draw a straight

line on the screen, the endpoints of the line can be identified by locating the

cursor in sequence at the two points and giving the command to construct the

line. There are various cursor control devices used in CAD, inducting pucks, mouse’s,

joysticks, trackballs, thumbwheels, light pens, and electronic tablets. An

input device for entering coordinates from an existing drawing into the CAD

system is a digit/t.er, which

consists of a large flat board and an electronic tracking element such as a

puck that can be moved across the surface of the board to record x and y-coordinate

positions.

Digital

Computer. CAD applications require a digital computer with a high-speed central

processing unit (CPU), math coprocessor to perform computation intensive

operations, and large internal memory. Today's commercial systems have 32bit

processors, which permit high-speed execution of CAD graphics and engineering

analysis applications.

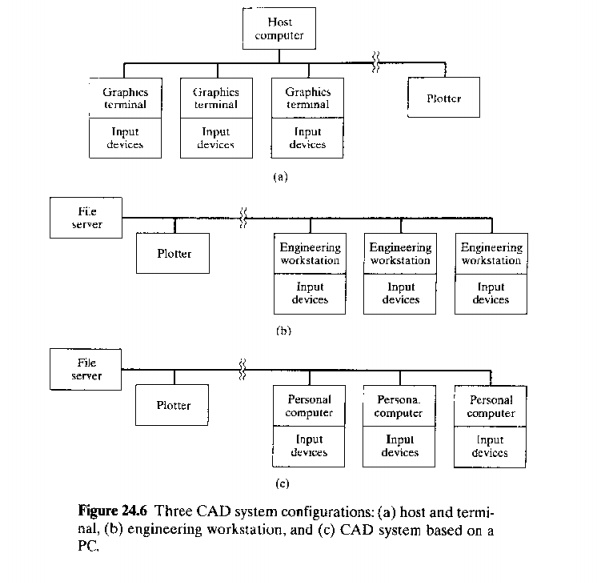

Several

CAD system configurations are available within the general arrangement shown in

Figure 24.5. Let us identify three principal configurations, illustrated in

Figure 24.6: (a) host and terminal, (b) engineering workstation, and (c) CAD

system based on a personal computer (PC).

The host and terminal was the original CAD

configuration in the Ig70s and early 1980s when the technology was first

developing. For many years, it was the only configuration available. In this

arrangement, a large mainframe computer or a minicomputer serves as the host

for one or more graphics terminals. These systems were expensive, each

installation typically representing an investment of a million dollars or more.

The powerful microprocessors and high-density memory devices that are so common

today were not available at that time. The only way to meet the computational

requirements for graphics processing and related CAD applications was to use a

mainframe connected 10 multiple terminals operating on a timesharing basis.

Host and terminal CAD systems are still used today in the automotive industry

and other industries in which it is deemed necessary to operate a large central

database.

An engineering workstation is a standalone

computer system that is dedicated to one user and capable of executing graphics

software and other programs requiring high-speed computational power. The

graphics display is a high-resolution monitor with a large screen. As shown in

our figure, engineering workstations are often networked to permit exchange of

data files and programs between users and to share plotters and data storage

devices.

A PC-based CAD system is a PC with a high-performance

CPU and medium to high resolution graphics display screen. The computer is

equipped with a large random access memory (RAM), math coprocessor, and large capacity

hard disk for storage of the large applications software packages used for CAD.

PC-based CAD systems can be networked 10 share file" output devices, and

for other purposes. Starting around 1996, CAD software developers began

offering products that utilize the excellent graphics environment of Microsoft

Windows NT, thus enhancing the popularity

and familiarity of PC-based CAD.

When the

engineering workstation is compared with the PC-based system, the former is

superior in terms of most performance criteria. Its capacity to efficiently

accomplish 3D geometric modeling and execute other advanced software exceeds

that of a PC, and this makes the workstation more responsive and interactive

than a PC-based CAD System. However, the performance characteristics of PCS are

improving each year, and the prices of engineering workstations are dropping

each year, so that the distinction between the two types is becoming blurred.

Plotters and Printers, The CRT

display is often the only output device physically located at the CAD

workstation. There is a need to document the design on paper. The peripherals

of the CAD system include one or more output devices for this purpose. Among

these output devices are the following

Pen plotters. These are .x y plotters

of various types used to produce high accuracy line drawings.

Electrostatic

plotters. These are faster device, based on the same technology as photocopying.

The resolution of the drawings from electrostatic plotters is generally lower

than those made by a pen plotter.

Dot-matrix

printers. In the operation of these printers, small hammers strike an ink ribbon against the paper to form a

drawing consisting of many ink dots.

Inkjet

printers. These arc similar to dot-matrix printers except that the dots arc formed by high-speed jets of ink

impacting the paper.

Storage Devices. Storage peripherals

are used in CAD systems to store programs

and data files. The storage medium is usually a magnetic disk or magnetic

tape, Files can be retrieved more quickly from magnetic disks, which

facilitates loading and exchange of files between CPU and disk. Magnetic tape

is less expensive, but more time is required to access a given file due to the

sequential file storage on the tape. His suited to disk backup, archival files,

and data transfer to output devices.

Related Topics