Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Product Design and CAD/CAM in the Production System

Product Design and CAD

PRODUCT DESIGN AND CAD

Product

design is a critical function in the production system. The quality of the

product design (i.e.. how well the design department does its job) is probably

the single most important factor in determining the commercial success and

societal value of a product. If the product design is poor, no matter how well

it is manufactured, the product is very likely doomed to contribute little to

the wealth and wellbeing of the firm that produced it. If the product design is

good, there is still the question of whether the product can be produced at

sufficiently low cost to contribute to the company's profits and success. One

of the facts of life about product design is that a very significant portion of

the cost of the product is determined by its design. Design and manufacturing

cannot he separated in Ihe production system. They are bound together

functionally, technologically, and economically.

Let us

begin our discussion of product design by describing the general process of

design. We then examine how computers are used to augment and automate the

design process.

The Design Process

The

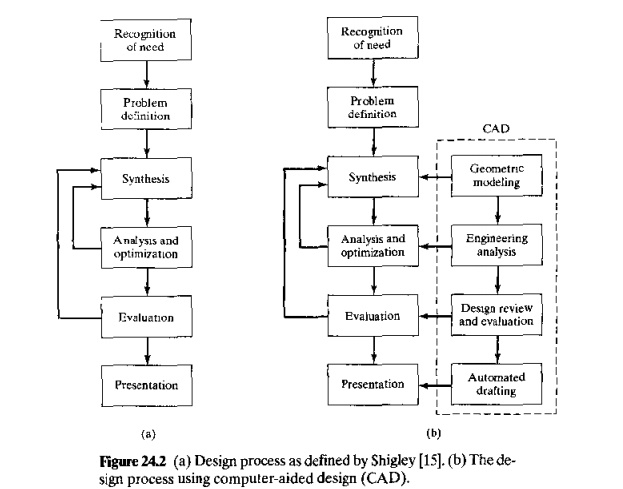

general process of design is characterized by Shigley as an iterative

process consisting of six phases: (1) recognition of need, (2) problem

definition, (3) synthesis, (4) analysis and optimization,(5) evaluation, and

(6) presentation. These six steps, and the iterative nature of the sequence in

which they are performed, are depicted in Figure 24.2(a).

Recognition

of need (1) involves the realization by someone that a problem exists for which

some corrective action can be taken in the form of a design solution. This

recognition might mean identifying some deficiency in a current machine design

by an engineer or perceiving of some new product opportunity by a salesperson.

Problem definition (2) involves a thorough specification of the item to be

designed. This specification includes the physical characteristics, function,

cost, quality, and operating performance.

Synthesis

(3) and analysis (4) are closely related and highly interactive in the design

process. Consider the development of a certain product design: Each of the subsystems

of the product must be conceptualized by the designer, analyzed, improved

through this analysis procedure, redesigned, analyzed again, and so on. The

process is repeated until the design has been optimized within the constraints

imposed on the designer. The individual components are then synthesized and

analyzed into the final product in a similar manner.

Evaluation

(5) is concerned with measuring the design against the specifications

established in the problem definition phase. This evaluation often requires the

fabrication and testing of a prototype model to assess operating performance,

quality, reliability, and other criteria. The final phase in the design

procedure is the presentation of the design. Presentation (6) is concerned with

documenting the design by means of drawings, material specifications, assembly

lists, and so on. In essence, documentation means that the design data base is

created.

Application

of Computers in Design

Computer-aided

design (CAD) is defined as any design activity that

involves the effective use of the computer to create,

modify, analyze, or document an engineering design. CAD is most commonly

associated with the use of an interactive computer graphics system, re

ferred 10

as a CAD system. The term CAD/CAM system is also used if it supports

manufacturing as well as design applications.

There are

several good reasons for using a CAD system to support the engineering design

function [l1J:

To increase the productivity of

the designer. This is accomplished by helping the designer to conceptualize the product and its components. In tum,

this helps reduce the time required bf the designer to synthesize, analyze, and

document the design.

To

improve the quality of Ihe design, The use of a CAD system with

appropriate hardware and software

capabilities permits the designer to do a more complete engineering analysis

and to consider a larger number and variety of design alternatives.

The

quality of the resulting design

is thereby improved.

To improve

design documentation. The graphical output of a CAD system results in better documentation of the design than

what is practical with manual drafting. The engineering drawings are superior,

and there is more standardization among the drawings, fewer drafting errors,

and greater legibility.

To create a manufacturing data base. In the

process of creating the documentation for

the product design (geometric specification of the product, dimensions of the

components, materials specifications, bill of materials, etc.), much of the

required data base to manufacture the product is also created.

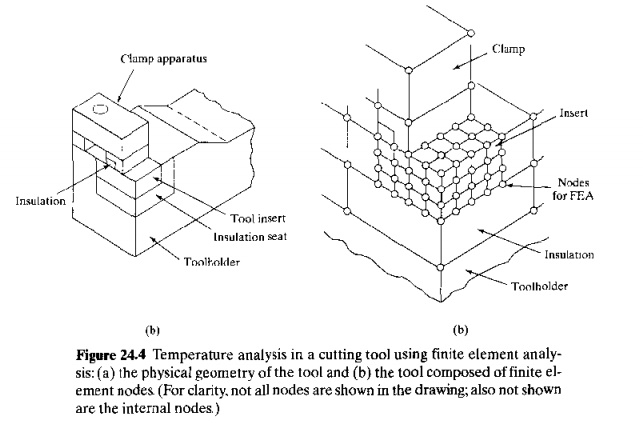

With

reference !O the six phases of design defined previously, a CAD system can

beneficially be used in four of the design phases, as indicated in Table 24.1

and Illustrated in Figure 24.2(b) as an overlay on the design process of

Shigley.

Geometric Modeling Geometric

modeling involves the use of a CAD system to

develop a mathematical description of the geometry of an object. The

mathematical description, called a geometric

model, is contained in computer memory. This pennits the user of the CAD

system to display an image of the model on a graphics terminal and toper-form

certain operations on the model. These operations include creating new

geometric models from basic building blocks available in the system, moving the

images around on the screen, zooming in on certain features of the image, and

so forth. These capabilities permit the designer to construct a model of a new

product (or Its components) or to modify an existing model.

There are

venous types of geometric models used in CAD. One classification distinguishes

between two dimensional (2D) and three dimensional (3D) models. Two dimensional

models are best utilized for design

problems in two dimensions, such as flat objects and layouts of buildings. In

the first CAD systems developed in the early 1970s, 2·0systems were used

principally as automated drafting systems. They were often used for 3D objects,

and it was left to the designer or draftsman to properly construct the various

views of the object. Three dimensional CAD systems are capable of modeling an

object in three dimensions. The operations and transformations on the model are

done by the system in three dimensions according to user instructions. This is

helpful in conceptualizing the object since the true 3D model can be displayed in various views and from different

angles.

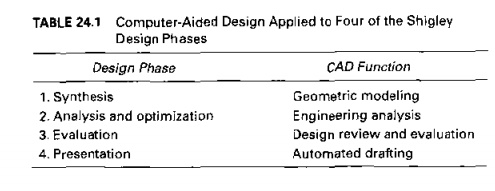

Geometric

models in CAD can also be classified as being either wireframe models or solid

models. A wireframe model uses inter-connecting lines (straight line segments)

to depict the object as illustrated in Figure 24.3(a).Wireframe models of

complicated geometries can become somewhat confusing because all ofthe lines

depicting the shape of the object are usually shown, even the lines

representing the other side of the object. Techniques

are

available for removing these so-called hidden lines, but even with this

improvement, wireframe representation is still often inadequate. Solid models

are a more recent development in geometric modeling. In solid modeling, Figure

24.3(b),an object is modeled in solid three dimensions, providing the user with

a vision of the object very much like it would be seen in real life. More

important for engineering purposes, the geometric model is stored in the CAD

system as a 3D solid model. thus providing a more accurate representation of

the object. This is useful for calculating mass properties, in assembly to

perform interference checking between mating components, and in other

engineering calculations.

Finally,

two other features in CAD system models are color and animation. Some CAD

systems have color capability in addition to black-and-white. The value of

color is largely to enhance {he ability of the user to visualize the object on

the graphics screen. For example, the various components of an assembly can be

displayed in different colors, thereby permitting the parts to be more readily

distinguished. Animation capability permits the operation of mechanisms and

other moving objects to be displayed on the graphics monitor.

Engineering

Analysis. After a particular design alternative has been developed, some form

of engineering analysis often must be performed as part of the design process.

The analysis may take the form of stress-strain calculations, heat transfer

analysis, or dynamic simulation. The computation are often complex and time

consuming, and before the advent of the digital computer, these analyses were

usually greatly simplified or even omitted in the design procedure. The

availability of software for engineering analysis on a CAD system greatly

increases the designer's ability and willingness. to perform a more thorough

analysis of a proposed design. The term computer-aided

engineering (CAE) is often used for engineering analyses performed by

computer. Examples of engineering analysis software in common use on CAD

systems include:

Mass

properties analysis, which involves the computation of such features of

a solid object as its volume, surface

area, weight, and center of gravity. It is especially applicable in mechanical

design. Prior to CAD, determination of these properties often required

painstaking and time consuming calculations by the designer.

Interference

checking. This CAD software examines 2D geometric models consisting of multiple

components to identify interferences between the components. It is useful in

analyzing mechanical assemblies, chemical plants, and similar multi component

designs

Tolerance

analysis. Software for analyzing the specified tolerances of a product'S components is used for the following

functions: (1) to assess how the tolerances may affect the product's function

and performance, (2) to determine how tolerances may influence the ease or

difficulty of assembling the product.and (3) to assess how variations in

component dimensions may affect the overall size of the assembly.

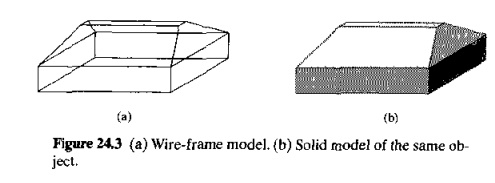

Finite element analysis. Software

for finite element analysis (FEA), also known as finite element modeling (FEM). is available for use on CAD systems

to aid in stress-strain, heat transfer, fluid flow, and other engineering

computations, Finite element analysis is a numerical analysis technique for

determining approximate solutions to physical problems described by

differential equations that are very difficult or impossible to solve. In FEA.

the physical object is modeled by an assemblage of discrete interconnected

nodes (finite elements), and the variable of interest (e.g., stress, strain,

temperature) in each node can be described by relatively simple mathematic

Figure

24.4 Temperature analysis in a cutting tool using finite element analysis: (a)

the physical geometry of the tool and (b) the tool composed of finite element

nodes. (For clarity. not all nodes are shown in the drawing; also not shown are

the internal nodes)

cal

equations, By solving the equations for each node. the distribution of values

of the variable throughout the physical object is determined. Figure 24.4

illustrates a finite element model to analyze temperatures in a cutting tool.

Kinematic

and dynamic analysis. Kinematic analysis involves the study of the

operation of mechanical linkages to analyze their motions. A typical kinematic

analysis consists of specifying the motion of one or more driving members of

the subject linkage, and the resulting motions of the other links are

determined by the analysis package. Dynamic analysis extends kinematic analysts

by including the effects of the mass of each linkage member and the resulting

acceleration forces as well as any externally applied forces

Discrete-event

simulation. This type of simulation is used to model complex

operational systems, such as a manufacturing cell or a material handling

system, as events occur at discrete moments in time and affect the status and

performance of the system. For example, discrete events in the operation of a

manufacturing cell include parts arriving for processing or a machine breakdown

in the cell. Measures of the status and performance include whether a given

machine in the cell is idle or busy and the overall production rate of the

cell. Current discrete-event simulation software usually includes an animated

graphics capability that enhances visualization of the system's operation.

Design Evaluation and Review. Design

evaluation and review procedures can be augmented

by CAD. Some of the CAD features that

are helpful in evaluating: and reviewing a proposed design include:

•Automatic dimensioning routines

that determine precise distance measures between surfaces on the geometric model identified hy the user.

Error

checking. This term refers 10 CAD algorithms that are used to review

the accuracy and consistency of dimensions and tolerances and to assess whether

the proper design documentation format has been followed

Animation

of discrete-event simulation solutions. Discrete event simulation

was described above in the context of engineering analysis. Displaying the

solution of the discrete-event simulation in animated graphic, is a helpful

means of presenting and evaluating the solution. Input parameters, probability

distributions, and other factors can he changed to assess their effect on the

performance of the system being modeled

Plant

layout design scores. A number of software packages are available for

facilities design. that is, designing the floor layout and physical arrangement

of equipment in a facility. Some of these packages provide one or more

numerical scores for each plant layout design, which allow the user to assess The

merits of the alternative with respect to material flow, closeness ratings. and

similar factors.

The

traditional procedure in designing a new product includes fabrication of a

prototype before approval and release of the product for production The

prototype serves as the "acid test" of the design, permitting the designer

and others to see. feel, operate, and test the product for any last-minute

changes or enhancements of the design. The problem with building a prototype is

that it is traditionally very time consuming; in some cases, months are

required to make and assemble all of the parts. Motivated by the need to reduce

this lead time for building the prototype. several new approaches have been

developed that rely on the usc of the geometric model of the product residing

in the CAD data file. We mention two of these approaches here: (1) rapid

prototyping and (2) virtual prototyping,

Rapid prototyping is a

general term applied to a family of fabrication technologies that allow engineering prototypes of

solid parts to be made in minimum lead time [12J. The common feature of the

rapid prototyping processes is that they fabricate the part directly from the

CAD geometric model. This is usually done by dividing the solid object into a

series of layers of small thickness and then defining the area shape of each

layer. For example, a vertical cone would be divided into a series of circular

layers, each circle becoming smaller and smaller as the vertex of the cone is

approached. The rapid prototyping processes then fabricate the object by

starting at the base and building each layer on top of the preceding layer to

approximate the solid shape. The fidelity of the approximation depends on the

thickness of each layer. As layer thickness decreases, accuracy increases.

There are a variety of layer-building

processes used in rapid prototyping. The most common process, called stereollthography, uses a photosensitive

liquid polymer that cures (solidifies) when Subjected to intense light. Curing

of the polymer is accomplished using a moving laser beam whose path for each

layer is controlled by means of the CAD model. By hardening each layer, one on

top of the preceding, a solid polymer prototype of the part is built.

Virtual prototyping. based on

virtual reality technology, involves the use of the CAD geometric model to construct a digital mockup of the product,

enabling the designer and others to obtain the sensation of the real physical

product without actually building the physical prototype. Virtual prototyping

has been used in the automotive industry to evaluate new car style designs. The

observer of the virtual prototype is able to assess the appearance of the new

design even though no physical model is on display. Other applications of

virtual prototyping include checking the feasibility of assembly operations,

for example, parts mating, access and clearance of parts during assembly, and

assembly sequence.

Automated

Drafting. The fourth area where CAD is useful (step 6 in the design process)

is presentation and documentation. CAD systems can be used as automated

drafting machines to prepare highly accurate engineering drawings quickly. It

is estimated that a CAD system increases productivity in the drafting function

by about fivefold over manual preparation of drawings

Related Topics