Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modernization of Railways and High Speed Trains

Ballastless Track

Ballastless Track

The technical concept of a

railway track consisting of ballast, sleepers, and rails is very old and has

stood the test of time. Such a system is simple and can be rapidly extended,

renewed, or dismantled. The general problem that occurs with ballasted tracks

is that the ballast material slowly deteriorates due to the load of the

traffic. The breaking of the ballast under the pressure exerted by the load

causes geometrical unevenness and clogging of the ballast bed by fine

particles. Therefore, regular maintenance is needed to restore track alignment.

The experience in Germany and other countries has been that the conventional

track may be used for speeds of up to 250 km/h but not beyond that. For higher

speeds, the construction of a ballastless track is required. In a ballastless

track, the rails are directly fastened to the concrete slab using elastic

fastenings. A ballastless track is expensive but is likely to require little or

no maintenance during its lifetime. The success of a ballastless track is

primarily based on the following advantages it offers.

Stability, precision, and comfort

A

ballastless track assures a permanently stable track and can withstand

the heavy load of high-speed train traffic. Its performance is characterized by

top quality, functionality and safety. The precise adjustment of the track up

to the last millimetre while it is being assembled at the construction site is

the prerequisite for ride comfort as well as reduction of pressure loads

experienced by the rolling stock.

Long life-span with practically

no maintenance With a service life of at least 60 years

and with little or no requirement for service or maintenance, a ballastless

track offers great viability and unmatched cost effectiveness in high-speed

operations.

Flexibility and end-to-end

effectiveness in application With its comparatively low

structural height and the possibility of the achievement of the optimal track

alignment, ballastless track technology offers highly attractive and beneficial

solutions as an end-to-end system technology for main-track and turnout

sections. This technology can be applied on a uniform basis on embankments,

bridges, and tunnels.

Basis for optimal routing of rail lines

The use of a ballastless track

for high-speed operations enables a more direct routing of train lines, with

tighter radii and greater slopes. These benefits enable the reduction, or even

elimination, of the costs of and the work required on civil engineering

structures. These benefits have led to the application of ballastless track

technology in the major projects for rail lines currently being undertaken in

Germany, where approximately 800 km of ballastless track has been installed

since 1991, as well as in other major projects around the world. The

ballastless track has found applications in many areas, as detailed in Table

32.3.

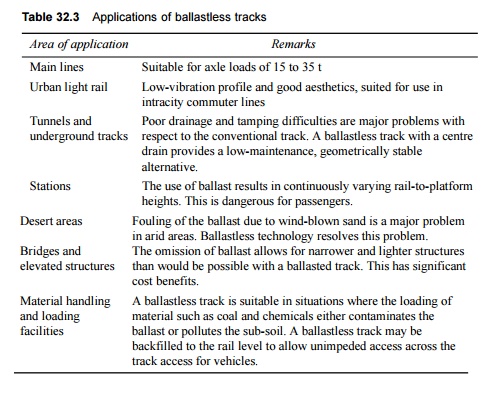

Table 32.3 Applications of

ballastless tracks

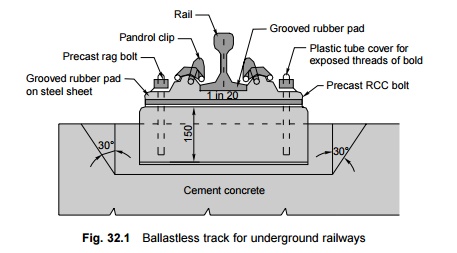

The Indian Railways does not have any plans for providing

ballastless tracks for high-speed routes because the maximum permissible speed

is only 140 km/h at present. However, ballastless tracks are provided in the

case of underground railways due to other considerations. Figure 32.1 shows the

cross section of a ballastless track for underground railways.

Related Topics