Chapter: Physics : Advanced Engineering Materials Metallic Glasses

Advanced Engineering Materials Metallic Glasses

ADVANCED ENGINEERING MATERIALS METALLIC

GLASSES

1 Introduction

2. Metallic glasses

2.1

Methods of preparation

2.2

Preparation of metallic glasses

2.3

Types of metallic glasses

2.4

Properties of metallic glasses

2.5

Applications of metallic glasses

3

Shape memory alloys

3.1

Shape memory alloys

3.2

Types of shape memory alloys

3.3

Characteristics of SMA

3.4

Commercial shape memory alloys

3.5

Advantages of shape memory alloys

3.6

Disadvantages of shape memory alloys

3.7

Applications of shape memory alloys

4

Nanotechnology

4.1

Nano materials

4.2

Comparison of different objects

4.3

Classification of nanomaterials

4.4

Top-down and bottom-up process

5

Synthesis techniques

5.1

Pulsed laser deposition

5.2

Chemical vapor deposition

6

Discuss the properties of nanophase materials

6.1

Physical properties

6.2

Magnetic properties

6.3

Mechanical properties

7

Applications of nanophase materials

8 Non-linear materials and bio-materials

8.1

Birefringence and Kerr effect

8.2

Non-linear properties and second harmonic generation

8.3

Non linear properties

8.4

Second harmonic generation

8.5

Biomaterials with their properties and applications

8.6

Classification of biomaterials

8.7

Applications

8.8

Ceramic

1 INTRODUCTION

New engineering

materials such as metallic glasses, shape memory alloys etc. are the advanced

materials, which are the integral part of our life. Both scientists and

technologists are searching for new materials, which can be used for high

technology research as well as applications.

In this chapter, we are

going to discuss the new engineering materials like metallic glasses, shpe

memory alloys, etc., along with their properties and its wide range of

applications.

2 METALLIC GLASSES

The Metallic glasses are materials which

have the properties of both metals and glasses.

Metallic glass = Amorphous metal

In general, metallic glasses are strong, ductile,

malleable, opaque and brittle. They also have good magnetic properties and high

corrosion resistance.

2.1METHODS

OF PREPARATION Principle

The principle used in

making metallic glasses is extreme rapid cooling of the molten alloy. The

technique is called as rapid quenching.

The cooled molten

alloys are fed into highly conducting massive rollers at high speeds to give

ribbons of metallic glasses.

2.1PREPARATION

OF METALLIC GLASSES

Principle

The principle used in making metallic glasses is

extreme rapid cooling of the molten metal alloy. This technique is called as

rapid quenching.

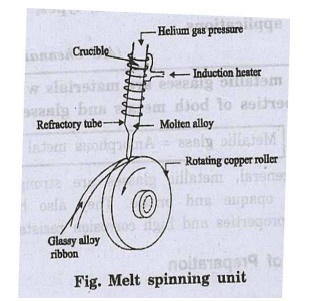

Melt spinning system

A melt spinner consists

of a copper roller over which a refractory tube with fine nozzle is placed. The

refractory tube is provided with induction heater as shown in fig.

The metal alloy is

melted by induction heating under inert gas atmosphere (helium or argon). The

properly super heated molten alloy is ejected through the fine nozzle at the

bottom of the refractory tube.

The molten alloy falls on the copper

roller which is rotated at high speed. Thus, the alloy is suddenly cooled to

form metallic glass. In this method a continuous ribbon of metallic glass can

be obtained.

2.3 TYPES OF METALLIC

GLASSES.

Metallic glasses are classified into two types:

(i)Metal –Metal metallic glasses

They are combination of metals

Metals Metals

Examples: Nickel (Ni) - Niobium (Nb)

Magnesium

(Mg) - Zinc

(Zn)

Copper

(Cu) - Zirconium (Zr)

(ii)

Metal –Metalloid metallic glasses

These

are combinations of metals and metalloids.

Examples: Metals Metalloids

Fe, Co, Ni - B, Si, C, P

2.4 PROPERTIES

OF METALLIC GLASSES

Structural properties

1. They

do not have any crystal defects such as grain boundaries, dislocation etc.

2. Metallic

glasses have tetrahedral close packing (TCP).

Mechanical properties

1. Metallic

glasses have extremely high strength, due to the absence of point defects and

dislocation.

2. They

have high elasticity.

3. They

are highly ductile.

4. Metallic

glasses are not work-harden but they are work –soften. (work harnening is a

process of hardening a material by compressing it).

Electrical properties

1. Electrical

resistivity of metallic glasses is high and it does not vary much with

temperature.

2. Due

to high resistivity, the eddy current loss is very small.

3. The

temperature coefficient is zero or negative.

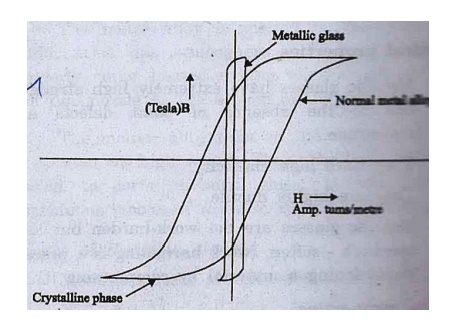

Magnetic properties

1. Metallic

glasses have both soft and hard magnetic properties.

2. They

are magnetically soft due to their maximum permeabilities and thus they can be

magnetised and demagnetized very easily.

3. They

exhibit high saturation magnetisation.

4. They

have less core losses.

5. Most

magnetically soft metallic glasses have very narrow hysteresis loop with same

crystal composition. This is shown in fig.

Fig.

Hysteresis loop of iron based alloy in crystalline and metallic glassy phase.

Chemical properties

1. They

are highly resistant to corrosion due to random ordering.

2. They

are highly reactive and stable.

3. They

can act as a catalyst. The amorphous state is more active than the crystalline

state from the catalytic point of view.

2.5APPLICATIONS

OF METALLIC GLASSES

Metallic glasses also called as met glasses have

found wide applications in different fields.

Structural application

1. They

posses high physical and tensile strength. They are superior to common steels

and thus they are very useful as reinforcing elements in concrete, plastic and

rubber.

2. Strong

ribbons of metallic glasses are used for simple filament winding to reinforce

pressure vessels and to construct large fly wheels for energy storage.

3. Due

to their good strength, high ductility, rollability and good corrosion

resistance, they are used to make razor blades and different kinds of springs.

Electrical and Electronics

1. Since

metallic glasses have soft magnetic properties, they are used in tape recorder

heads, cores of high-power transformers and magnetic shields.

2. They

use of metallic glasses in motors can reduce core loss very much when compared

with conventional crystalline magnets.

3. Superconducting

metallic glasses are used to produce high magnetic fields and magnetic

levitation effect.

4. Since

metallic glasses have high electrical resistance, they are used to make

accurate standard resistance, computer memories and magneto resistance sensors.

Metallic glasses as transformer core

material

5. Metallic

glasses have excellent magnetic properties. When they are used as transformer

core, they give maximum magnetic flux linkage between primary and secondary

coils and thus reduce flux leakage losses.

In view of their features like small thickness,

smaller area, light weight, high resistivity, soft magnetic property and

negligible hysteresis and eddy current loss, metallic glasses are considered as

suitable core materials in different frequency transformers.

Nuclear reactor engineering

1.The magnetic

properties of metallic glasses are not affected by irradiation and so they are

useful in preparing containers for nuclear waste disposal and magnets for

fusion reactors.

2.Chromium and

phosphorous based (iron chromium, phosphorous-carbon alloys) metallic glasses

have high corrosion resistances and so they are used in iner surfaces of

reactor vessels, etc.

Bio-medical Industries

1. Due

to their high resistance to corrosion, metallic glasses are ideal materials for

making surgical instruments.

2. They

are used as prosthetic materials for implantation in human body.

2 SHAPE

MEMORY ALLOYS

3.1 SHAPE MEMORY ALLOYS

A group of metallic

alloys which shows the ability to return to their original shape or size (i.e.,

alloy appears to have memory) when they

are subjected to heating or cooling are called shape memory alloys.

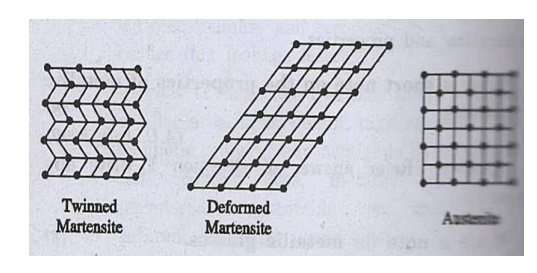

Phase of shape memory alloys

Martensite and

austenite are two solid phases in SMA as shown in fig.

Fig. Phases of SMA

Martensite is

relatively soft and it is easily deformable phase which exists at low

temperature (monoclinic) (fig.)

(i)

Austenite is a phase that occurs at high

temperature having a crystal structure and high degree of symmetry (cubic)

(fig.).

3.2TYPES

OF SHAPE MEMORY ALLOYS

There are two types of shape memory alloys

(i)

One-way shape memory alloy

(ii)

Two-way shape memory alloy

A material which

exhibits shape memory effect only upon heating is known as one-way shape

memory. A material which shows a shape memory effect during both heating and

cooling is called two-way shape memory.

Examples of shape memory alloys

Generally, shape memory

alloys are intermetallic compounds having super lattice structures and

metallic-ionic-covalent characteristics. Thus, they have the properties of both

metals and ceramics.

Ni –Ti alloy (Nitinol)

Cu –Al –Ni alloy

Cu –Zn –Al alloy

Au –Cd alloy

Ni –Mn –Ga and Fe based

alloys

3.3CHARACTERISTICS

OF SMAS

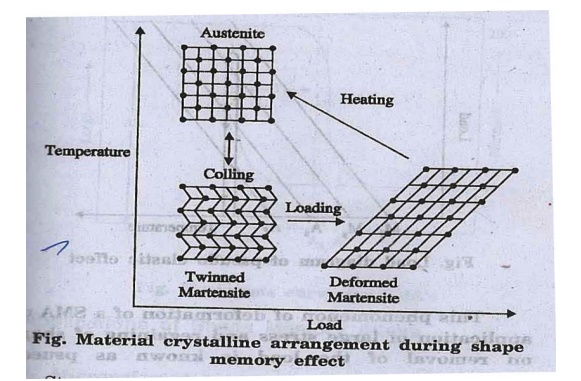

1. Shape memory

effect

The change of shape of

a material at low temperature by loading and regaining of original shape by

heating it, is known as shape memory effect.

The shape memory effect

occurs in alloys due to the change in their crystalline structure with the

change in temperature and stress.

While loading, twinned

martensite becomes deformed martensite at low temperature.

On heating, deformed

martensite becomes austenite (shape recovery) and upon cooling it gets

transformed to twinned martensite (fig.).

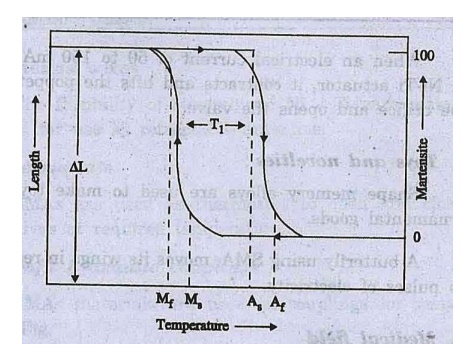

2.SMAs exhibit changes in electrical resistance,

volume and length during the transformation with temperature.

3.The mechanism involved in SMA is reversible

(austenite to martensite and vice versa.)

4. Stress

and temperature have a great influence on martensite transformation.

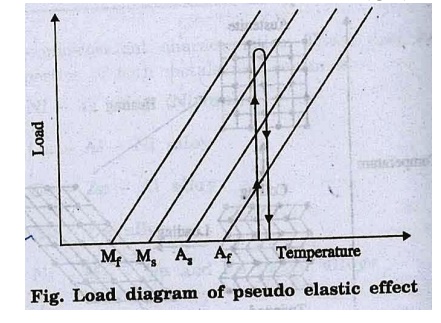

5. Pseudo

elasticity

Pseudo –elasticity

occurs in shape memory alloys when it is completely in austenite phase

(temperature is greater than Af austenite finish

temperature).

Unlike the shape memory

effect, Pseudo-elasticity occurs due to stress induced phase transformation

without a change in temperature. The load on the shape memory alloy changes

austenite phase into martensite (Fig.).

As soon as the loading decreases the martensite

begins to transform to austenite.

This phenomenon of

deformation of a SMA on application of large stress and regaining of shape on

removal of the load is known as pseudo elasticity.

This pseudo elasticity is also known as super

elasticity

6. Hysteresis

The temperature range

for the martensite to austenite transformation which takes place upon heating

is somewhat higher than that for the reverse transformation upon cooling.

The difference between

the transition temperature upon heating and cooling is called hysteresis. The

hysteresis curve for SMAs is shown in fig.

The

difiference of temperature is found to be 20-30oC,

3.4 COMMERCIAL SHAPE

MEMORY ALLOYS

The only two alloy systems that have achieved any

level of commercial exploitation are,

(i)

Ni-Ti alloys, and

(ii)

Copper base alloys.

Properties

of the two systems are quite different.

1. Nickel-Titanium

Alloys

The basis of the

Nickel-Titanium alloy is the binary, equi-atomic inter-metallic compound of

Ti-Ni. The inter-metallic compound is extraordinary because it has moderate

solubility range for excess Nickel or Titanium, as well as most other metallic

elements. This solubility allows alloying with many of the elements to modify

both the mechanical properties and the transformation properties of the system.

Excess Nickel strongly depresses the transformation temperature and increases

the yield strength of the austenite. The contaminants such as Oxygen and Carbon

shift the transformation temperature and degrade the mechanical properties.

Therefore, it is also desirable to minimize the amount of such elements.

Properties:

(i)

The Ni-Ti alloys have greater shape

memory strain upto 8.5% tend to be much more thermally stable.

(ii)

They have excellent corrosion resistance

and susceptibility, and have much higher ductility.

(iii)

Machining by turning or milling is very

difficult except with special tools.

(iv)

Welding, brazing or soldering the alloys

is generally difficult.

(v)

The material do respond well to abrasive

removal such as grinding, and shearing.

(vi)

Punching can be done if thicknesses are

kept small.

3.5 ADVANTAGES OF SHAPE

MEMORY ALLOYS

They are simple, compact and high safe.

They have good bio –compatibility.

They have diverse applications and offer clean, silent and spark-free

working condition

They have good mechanical properties and are strong corrosion-resistant.

3.6DISADVANTAGES

OF SHAPE MEMORY ALLOYS

They have poor fatigue properties.

They are expensive.

They have low energy efficiency.

3.7 APPLICATIONS

OF SHAPE MEMORY ALLOYS

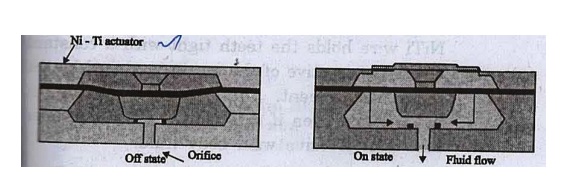

1. Microvalve (Actuators)

One of the most common

applications of SMAs is mocrovalves. Fig. shows a microvalve made of Ni –Ti

alloy actuator. Actuator is a microsensor that can trigger the operation of a

device. The electrical signal initiates an action.

Fig. Schematic of microvalves that open

and close according to temperature

When an electrical

current of 50 to 150 mA flows in Ni-Ti actuator, it contracts and lifts the

poppet from the orifice and opens the valve.

2. Toys and novelties

Shape

memory alloys are used to make toys and ornamental goods.

A

butterfly using SMA. Moves its wings in response to pulses of electricity.

3. Medical field Blood

clot filters

(i)

Blood clot filters are SMAs, properly

shaped and inserted in veins to stop the passing blood clots.

When the SMA is in contact with the clot at a lower

temperature, it expands and stops the clot and blood passes through the veins.

(ii)

They are used in artificial hearts.

(iii)

Orthodontic applications

NiTi wire holds the

teeth tight with a constant stress irrespective of the strain produced by the

teeth movement. It resists permanent deformation even if it is bent. NiTi is

non-toxic and non-corrosive with body fluid.

(iv)

SMAs (NiTi) are used to make eye glass

frames and medical tools. Sun-glasses made from superelastic Ni-Ti frames

provide good comfort and durability.

4. Antenna

wires

The

flexibility of superelastic Ni –Ti wire makes it ideal for use as retractable

antennas.

5. Thermostats

SMAs

are used as thermostat to open and close the valves at required temperature.

6. Cryofit hydraulic couplings

SMAs

materials are used as couplings for metal pipes

7. Springs, shock absorbers, and valves

Due to the excellent

elastic property of the SMAs, springs can be made which have varied industrial

applications. Some of them are listed here.

Engine micro valves

Medical stents (Stents

are internal inplant supports provided for body organs)

Firesafety valves and

Aerospace latching

mechanisms

8. Stepping motors

Digital

SMA stepping motors are used for robotic control.

9. Titanium-aluminium

shape memory alloys offer excellent strength with less weight and dominate in

the aircraft industry. They are high temperature SMAs, for possible use in

aircraft engines and other high temperature environments.

4

NANOTECHNOLOGY

4.1 NANO MATERIALS

Nanoparticles are the

particles that have three dimensional nanoscale, the particle is between 1 and

100 nm in each spatial dimension. A nanometer is a unit of measure equal to

one-billionth of a meter, or three to five atoms across.

Nanotechnology is the design, fabrication and use of

nanostructured systems, and the growing, assembling of such systems either

mechanically, chemically or biologically to form nanoscale architectures,

systems and devices.

4.2COMPARISON

OF DIFFERENT OBJECTS

1. Diameter of sun - 1,393,000km

2. Diameter of earth - 1,28,000km

3. Height of Himalaya mountain - 8,848km

4. Height of man - 1.65km

5. Virus - 20-250nm

6. Cadmium sulphide nanoparticle - 1-10nm

4.3CLASSIFICATION

OF NANOMATERIALS

1. Clusters

A collection of atoms or reactive molecules up to

about 50 units.

2. Colloid

A stable liquid phase containing particles in 1 to

1000 nm range. A colloidal particle is

one such 1 to

1000 nm sized particle.

3. Nanoparticle

A solid particle in the 1 to 100 nm range that could

be non-crystalline, an aggregate of crystallites, or a single crystallite.

4. Nanocrystal

A solid particle that is a single crystal in the

nanometer size.

5. Nanostructured or Nanoscale Material

Any solid materials has a nanometer dimension.

Three dimensions --- > Particles

Two dimensions --- > Thin films

One dimension --- > Thin wire

6. Quantum Dots

A particle that exhibits a size quantization effect

in at least one dimension.

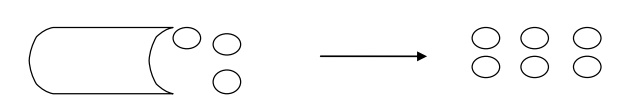

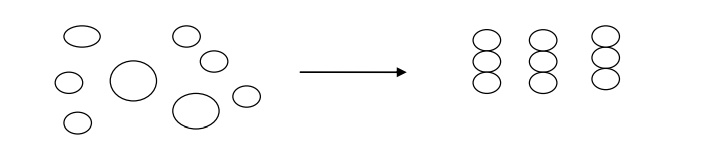

4.4 TOP-DOWN AND

BOTTOM-UP PROCESSS

1. Top-down Process

In this processes, bulk

materials are broken into nano sized particles as shown in

In to-down processes,

the building of nanostructures starting with small components like atoms and

molecules that are removed from a bulk material so as to obtain desired

microstructure.

2. Bottom-up Processes

In this processes, nano

phase materials are produced by building of atom by atom as shown in.

This processes building

larger objects from smaller buildings blocks. Nanotechnology seeks to use atoms

and molecules as those building blocks. This is the opposite of the top-down

approach. Instead of taking material away to make structures, the bottom-up

approach selectively adds atoms to create structures.

5 SYNTHESIS TECHNIQUES

Nano materials are newly developed materials with

grain size at the nanometre range (10-9m)

i.e., in the order of 1 –100 nm. The particle size

in a nano material is in the order of nm.

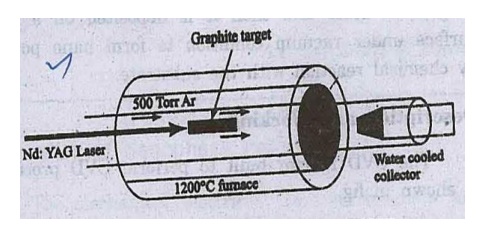

5.1 PULSED LASER

DEPOSITION

Priniciple

The laser pulse of high

intensity and energy is used to evaporate carbon from graphite. These

evaporated carbon atoms are condensed to from nanotubes.

Description

The experimental

arrangement of pulsed laser4 deposition is shown in fig. A quartz tube which

contains a graphite target is kept inside a high temperature muffle furnace.

Fig.

Pulsed Laser Deposition CNT

This quartz tube is

filled with argon gas and it is heated to 1473 K. A water cooled copper

collector is fitted at the other end of the tube. The target material graphite

contains small amount of nickel and cobalt as a catalyst to nucleate the

formation of nanotubes.

Working

When an intense pulse

of laser beam is incident on the target, it evaporates the carbon from the

graphite. The evaporated carbon atoms are swept from the higher

temperature argon gas to the colder copper collector.

When the carbon atoms reach the colder copper

collector, they condense into nanotubes.

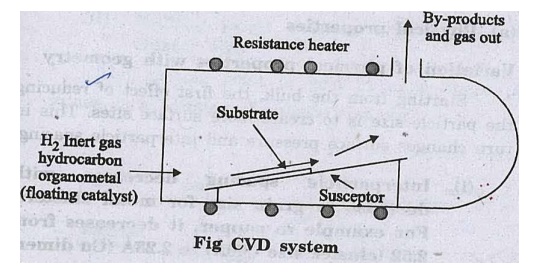

5.2CHEMICAL

VAPOUR DEPOSITION

The deposition of nano

films from gaseous phase by chemical reaction on high temperature is known as chemical vapour deposition.

This

method is used to prepare nano-powder.

Principle

In this technique,

initially the material is heated to gaseous state and then it is deposited on a

solid surface under vacuum condition to form nano powder by chemical reaction

with the substrate.

Description and Working

The

CVD reactor built to perform CVD processes is shown in fig.

Chemical vapour

deposition (CVD) involves the flow of a gas with diffused reactants (substances

to be deposited in the vapour) over a hot substrate surface. The gas that

carries the reactants is called the carrier gas.

While the gas flows

over the hot solid surface, the heat energy increases chemical reactions of the

reactants that form film during and after the reactions.

The byproduct of the

chemical reactions are then removed. The thin film of desired composition can

thus be formed over the surface of the substrate.

6 PROPERTIES OF NANOPHASE MATERIALS.

Properties of Nanophase Particles

The mechanical,

electrical, chemical, magnetic and structural properties of nanophase materials

change with the reduction in the particle size of the material.

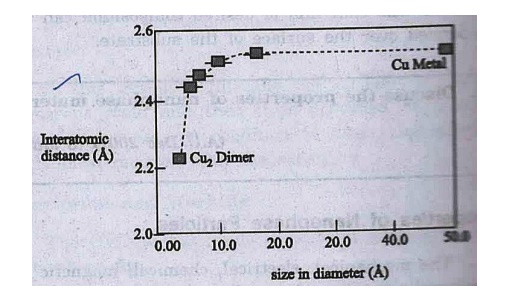

6.1 PHYSICAL PROPERTIES

Variation of physical properties with

geometry

Starting from the bulk,

the first effect of reducing the particle size is to create more surface sites.

This in turn changes surface pressure and interparticle spacing.

(i)

Interparticle spacing decreases

with decrease in grain size for metal clusters.

For

example in copper, it decrease from 2.52 (cluster size –50A) to 2.23A (Cu

dimer) fig.

The change in inter

particle spacing and large surface to the volume ratio in particles have a

combined effect on material properties. Therefore, the nanophase materials have

very high strength and super hardness.

Because of the cluster

of grains, the nano phase materials are mostly free from dislocations and

stronger than conventional metals.

Fig.

Interatomic distance in Cun as a function of grain size.

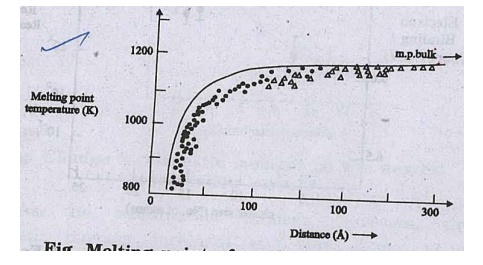

(ii)

Melting point reduces with decrease

in cluster size.

The melting point of

gold in nano phase (Aun) varies as a function of particle size

(fig.)

Fig.

Melting point of small Aun particles as a function of size

The melting point decreases

from 1200 K to 800 K when the particle size decreases from 300 A to 20 A.

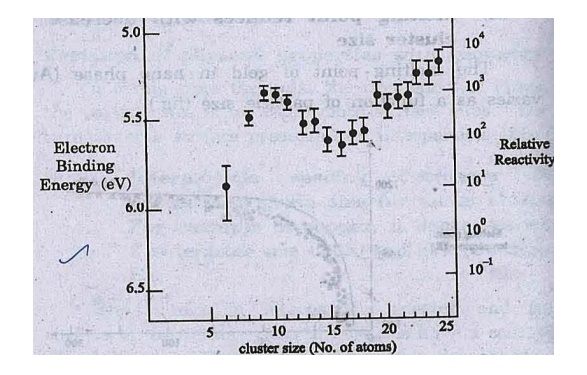

(iii)

Ionisation potential changes with

cluster size of the nanograins.

The electronic bands in

metals become narrower when the size is reduced from bulk which changes the value

of ionization potential.

Fig. shows the

ionization potential and reactivity of Fen clusters as a function of

size. Ionisation potentials are higher at small sizes than that for the bulk

and show marked fluctuations as a function of size.

Fig. Ionisation

potential and reactivity of Fen clusters as a function of size (iv) The large

surface to volume ratio, the variations in geometry and the electronic structure

have a strong effect on catalytic properties.

As an example, the

reactivity of small clusters is found to vary by higher orders of magnitude

when the cluster size is changed by only a few atoms.

6.2 MAGNETIC PROPERTIES

Nanoparticles

of non-magnetic solids also exhibit totally new type of magnetic properties.

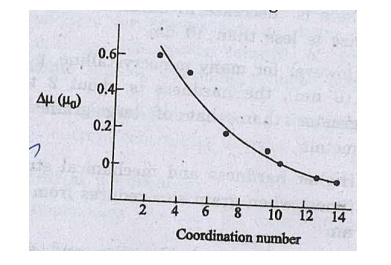

(i)

Bulk magnetic moment increases with

decrease in co-ordination number

The change in magnetic

moment on the nearest coordination number is shown in fig.-0

Fig.

Change in magnetic moment on the nearest coordination number

As the coordination

number decreases, the magnetic moment increases with the atomic value which

means that small particles are more magnetic than the bulk material.

The magnetic moment of iron (Fe) of nanoparticles is

30% more than that of bulk. At smaller sizes, the clusters become

spontaneously magnetic.

(ii)

The nano-materials shows variation in

their magnetic property when they change from bulk state to cluster

(nano-particle) state.

(iii)

Non-magnetic materials become magnetic

when the cluster size reduces to 80 atoms.

6.2 MECHANICAL

PROPERTIES

(i) In

nanophase materials, the elastic strength is low however, its plastic behavior

is high.

(ii) In

some nanophase materials, it is noted that there is decrease in hardness when

the grain size is less than 10 nm.

However for many nanocrystalline, pure metals (10

nm), the hardness is about 2 to 7 times greater than that of large-grained

(>1 μ m) metals.

(iii)Higher hardness

and mechanical strength (2-7 times) when grain size reduces from 1 μ m

to 10 nm.

(iv)

It has very high ductility and

superplastic behavior at low temperatures.

7 APPLICATIONS OF

NANOPHASE MATERIALS.

1.Materials Technology

We can synthesis harder metals having hardness 5 times higher than normal

metals using nanoparticles.

Stronger, lighter, wear resistant, tougher and flame retardant polymers

are synthesized with nanoparticles as fillers. They are used in replacement of

body parts and metals (bio-materials).

We can produce unusual colour paints using nanoparticles since nanoparticles

exhibit entirely different optical properties.

Nanophase materials are used in annoelectronic devices such as

nanotransistore, ceramic capacitors for energy storage, noise filters and

stabilizers. The special features of these devices include smaller sizes and

reduced power losses.

ZnO thermistors are used in thermal –protection and current-controlling

devices.

2. Information Technology

Nanoparticles are used for data storage.

Quantum electronic devices have started replacing bulk conventional

devices.

Nano materials are used to produce very tiny permanent magnets of high

energy products. Hence, they are used in high-density magnetic recording.

Magnetic devices made of Cu-Fe alloy are used in RAM, READ / WRITE heads

and sensors.

Quantum dots, quantum wells and quantum wires are mainly produced from

semiconductor nanomaterials. Hence, they are used in computer storage (memory)

devices.

3. Biomedicals

Biosensitive nanoparticles are used for tagging of DNA and DNA chips.

Controlled drug delivery is possible using nanotechnology. Diffusion of

medicine through nanoporous polymer reservoir as per the requirement is very

useful in controlling the disease.

Nanostructured ceramics readily interact with bone cells and bence finds

applications as an implant material.

4. Energy storage

Since the hydrogen absorbing capability increases with decrese of size of

nanoparticles, nanoparticles of Ni, Pd and Pt are useful in hydrogen storage

devices.

Metal nanoparticles are very useful in fabrication of ionic batteries.

5. Optical devices

Nanomaterials are used

in making effici

Nanoparticulate zinc oxide is used to manufacture effective Sunscreens.

Nanoparticles are used in the coatings for eye glasses to protect from

scratch or breakage.

6. Transmission

lines

Nanophase materials are used in the fabrication of

signal processing elements such as filters, delay lines, switches etc.

7. Nanomicro-Electro

Mechanical Systems (Nano MEMS) have direct

implications on integrated circuits, optical switches, pressure sensors

and mass sensors.

8. Molecular

Nano-Technology (MNT) is aimed to develop robotic

machines, called assemblers on a molecular scale, molecular-size power

sources and batteries.

9. Underwater

nanosensor networks are used to detect the movement of ships

in an efficient manner with faster response. They can also detect

chemical, biological or radiological materials in cargo containers.

8 NON-LINEAR MATERIALS

AND BIO-MATERIALS

8.1 BIREFRINGENCE AND KERR EFFECT.

The appearance of

double refraction under the influence of an external agent is known as

artificial double refraction or induced birefringence.

Optical Kerr Effect

Anisotropy induced in

an isotropic medium under the influence of an electric field is known as Kerr

effect.

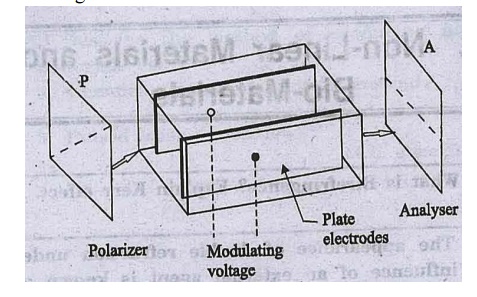

A sealed glass cell

known as Kerr cell filled with a liquid comprising of asymmetric molecules is

used to study the Kerr effect.

Two plane electrodes

are placed in parallel to each other. When a voltage is applied to there electrodes,

a uniform electric field is produced in the cell.

The Kerr cell is placed

between a crossed polarizer system (Fig), When the electric field is applied,

the molecules of the liquid tend to align along the field direction.

As the molecules are asymmetric,

the alignment causes anisotropy and the liquid becomes double refracting. The

induced birefringence is proportional to the square of the applied electric

field E and to the

wavelength λ of

incident light.

Fig. Kerr effect –Birefringence is

induced in a liquid subjected to an electric field

The change in

refractive influx is given by

∆μ= K λE2

Where

K is known as the Kerr constant

8.2 EXPLAIN NON-LINEAR

PROPERTIES AND SECOND HARMONIC GENERATION. Basic Principle of Non Linear

Properties

We know that a light

wave is electromagnetic in nature ie., it consists of electric and magnetic

fields. When the light propagates through a material, it changes the properties

of the medium, such as the refractive index. It depends on the electric and

magnetic fields associated with the light.

For example, we could

not observe nonlinear effects with the ordinary light beam of low intensity,

since the electric and magnetic fields associated with the light beams is very

weak.

With the invention of

laser, it is now possible to have electric fields which are strong enough to

observe interesting non linear effects.

Thus if electric and

magnetic fields are strong enough, the properties of the medium will be

affected which in turn will affect the propagation of the light beam.

8.3NON

LINEAR PROPERTIES

Few of the nonlinear phenomena observed are

1. Second

harmonic generation

2. Optical

mixing

3. Optical

phase conjugation

4. Soliton

8.4SECOND

HARMONIC GENERATION

In a linear medium,

polarization P is directly proportional to the electric field E

P

∝E

P

= εoχE

Whereo ε-

Permittivity of free space

χ -

electrical susceptibility

In nonlinear medium for

higher fields ie., higher intensities of light the non linear effects are

observed.

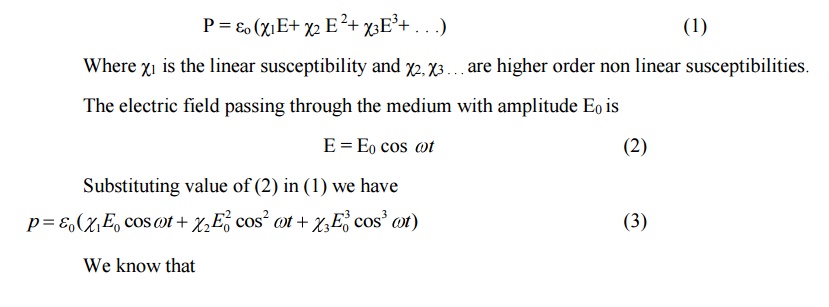

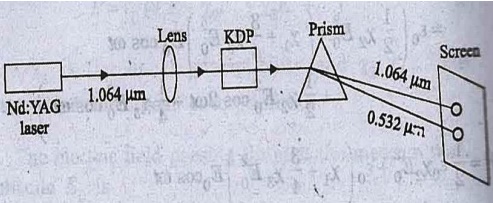

In the above equation,

1st term gives rise to dc field across the medium, the second

term gives external polarization and is called first or fundamental harmonic polarisability.

The third term which

oscillates at a frequency 2w is called second harmonic of polarization and

other terms are referred as higher harmonic polarization.

Both first term (dc

field) and third term (second harmonic of polarization) added together is

called optical rectification.

The second harmonic

generation is possible only the crystals lacking inversion symmetry. SHG

crystals are quartz, potassium dihydrogen phosphate (KDP), Ammonium dihydrogen

phosphate (ADP), Barium titante (BaTiO3) and Lithium lodate (LiIO3)

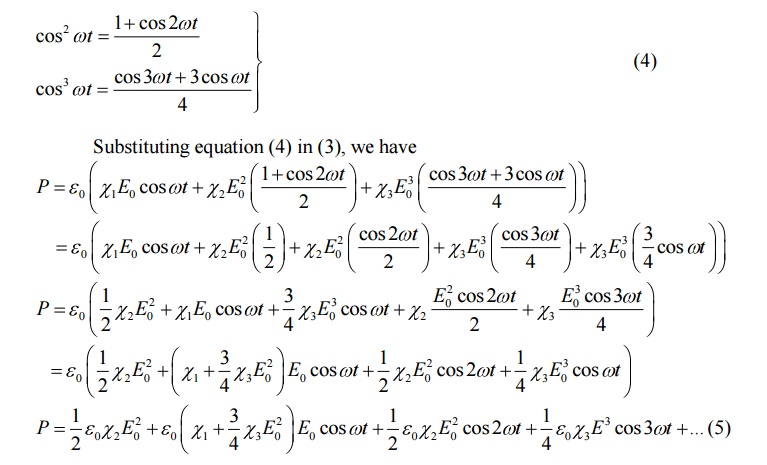

The observation of

second harmonic generation by KDP is shown in figure.

Fig.

Arrangement for observing second harmonic generation

When the fundamental

radiation (1.064 m) from Nd: YAG laser is sent through SHG crystal like KDP,

conversion takes place to double the frequency. i.e., half the wavelength

(0.532 m) takes place.

8.5 BIOMATERIALS WITH THEIR PROPERTIES

AND APPLICATIONS.

The materials which are

used for structural applications in the field of medicine are known as

Biomaterials.

In the recent years,

new biomaterials like nanobiomaterials are emerging up due to the requirements

in the medical field for different applications.

8.6 CLASSIFICATION OF BIOMATERIALS

Based

on the applications in the field of medicine, biomaterials are classified as

1. Metals

and alloys biomaterials

2. Ceramics

biomaterials.

3. Polymer

biomaterials.

4. Composite

biomaterials

Sometimes, a single

material mentioned above cannot fulfill the complete requirements imposed for

specific applications. In such case, combinations of more than one material are

required.

Metals and Alloys

Metals and alloys are

used as biomaterials due to their excellent electrical and thermal conductivity

and mechanical properties.

TYPES OF BIOMATERIALS USING METALS AND

ALLOYS

1. Cobalt

based alloys

2. Titanium

3. Stainless

steel

4. Protosal

from cast alloy

5. Conducting

metals such as Platinum

8.7APPLICATIONS

The metals and alloys biomaterials are used in implant

and orthopedic applications.

1. Stainless

steel is the predominant implant alloy. This is mainly due to its ease

of fabrication and desirable mechanical properties and corrosion resistant.

2. Proposal

from cast alloy of Co –Cr –Mo is used to make stem and used for implant hip

endoprosthesis.

3. The

advanced version of protosal –10 from Co –Ni –Cr –Mo

alloy is widely used in Hip joints, Ankle joints, Knee joints, leg

lengthening spaceas.

4. ASTMF

–136 (composition of Ti –6A1 –4V, EL1 alloy, forged) due to its high strength /

weight ratio, high corrosion resistance and high bio compatibility, this alloy

is used in dental applications for making screws, wires and artificial teeth.

5. Ni

–Ti shape memory alloy is used in dental arch wires, micro surgical

instruments, blood clot filters, guide wires etc.

8.8CERAMICS

Ceramics are used as biomaterials due to their high

mechanical strength and biocompatibility.

Types of Bio-Ceramic materials.

1. Tricalcium

phosphate

2. Metal

oxides such as Al2O3 and SiO2

3. Apatite

ceramics

4. Porous

ceramics

5. Carbons

and Alumina

Applications

1. Ceramic

implants such as Al2O3 and with some SiO2 and

alkali metals are used to make femoral head. This is made from powder

metallurgical process.

2. Tricalcium

phosphate is used in bone repairs.

3. Orthopedic

uses of alumina consists of hip and knee joints, tibical plate, femur shaft,

shoulders, radius, vectebra, leg lengthening spaces and ankle joint prosthesis.

Porous alumina is also used in teeth roots.

4. Apatite

ceramics are new bio active ceramics. They are regarded as synthetic bone,

readily allows bone ingrowth, better than currently used alumina Al2O3.

5. Carbon

has good biocompatibility with bone and other tissues. It has high strengths

and an elastic molecules close to that of bone.

6. Carbon

coatings find wide applications in heart valves, blood vessel grafts,

percutaneous devices because of exceptional compatibility with soft tissues and

blood.

7. Percutaneous

carbon devices containing high density electrical connectors have been used for

the chronic stimulation of the cochlea for artificial hearing and stimulation

of the visual cortex to aid the blind.

Bio Polymers

Biopolymers

are macromolecules (protein, nucleic acids and polysachacides) formed in

nature during the growth cycles of all

organisms.

Biopolymers find

variety of applications as biomaterials. The most prominent among them are

collagens, muco-polysaccharides –chitin, collagens and its derivatives.

Collagnes which are

major animal structural proteins are widely used in a variety of forms such as

solution, gel, fibers, membranes, sponge and tubing for large number of

biomedical applications including drug delivery system, vessels, valves corneal

prosthesis, wound dressing, cartilage substitute and dental applications.

Biomaterials in Opthamology

Biomaterials find

important applications in opthalmology. They are used to improve and maintain

vision. Eye implants are used to restore functionality of cornea, lens, etc,

when they are damaged or diseased.

The biomaterials

include viscoelastic solutions intraocular lenses, contact lenses, eye shields,

artificial tears, vitreous replacements, correction of corneal curvature.

Dental Materials

Polymers, composites,

ceramic materials and metal alloys are four main groups of materials used for

dental applications.

A large number of materials are tested for porous

dental implants, which include stainless steel,Co –Cr –Mo alloy, PMMA,

proplast and Daceon, velour coated metallic implants, porous calcium aluminate

single crystal alumina, bioglass, vitreous and pyrolytic carbons.

The dental applications

include impression materials, dentine base and ceorons, bridges, inlays and

repair or cavities, artificial teeth, repair of alveolar bone, support for

mandible .

Related Topics