Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Automotion and Control Technologies

Advanced Automation Functions

ADVANCED AUTOMATION

FUNCTIONS

In

addition to executing work cycle programs, an automated system may be capable

of executing advanced functions that are nOI specific to a particular work

unit. In general, the functions are concerned with enhancing the performance

and safety of the equipment. Advanced automation functions include the

following: (1) safety monitoring, (2) maintenance and repair diagnostics, and

(3) error detection and recovery.

Advanced

automation function> are made possible by special subroutines included in

the program of tnsttuctluns. In some cases, the runcnons provide information

only and

do not

involve any physical actions by the control system, An example of this case

includes reporting a list of preventive maintenance tasks that should be

accomplished. Any actions taken on the basis of this report are decided by the

human operators and managers of the system and not by the system itself 11\ other cases, the program of

instructions must be physically executed by means of the control system using

available actuators. A simple example of this case is a safety monitoring

system that sounds an alarm when a human worker gets dangerously close to the

automated system.

Safety Monitoring

One ot

the significant reasons for automating a manufacturing operation is to remove

workcr{s) from a hazardous working environment. An automated system is often

installed to perform a potentially dangerous operation that would otherwise be

accomplished manually by human workers '.However, even in automated systems.

wo~kers arestill needed to service

the system. at periodic time intervals If not fulltime. Accordingly. it is

important that the automated system

be designed to operate safely when workers arc in attendance. In addition.rt is

essential that the automated system carry QUills proCI;:SS in a way that is not

selfdestructive. Thus. there are two reasons for providing an automated system

with a safety monitoring capability: (1) to protect human workers in the

vicinity of the system ami (2) to protect the equipment associated with the

system.

Safety

monitoring means more than the conve.ntionalsafety measures til ken in a ill: al· ufacturing operation, such as protective shields around the operation

or the kinds of manual devices that might be utilized by human workers. such as emergency

stop buttons. Safety moniroringin an automated system

involves the use or sensors to track the system's operation and identify

conditions and events that are unsafe or potentially unsafe. The safety

monitoring system is programmed to respond to unsafe conditions in some

appropriate way. Possible responses to various hazards might include one or

more of the following:

complete stoppage

of the automated system

sounding an alarm

reducing the operating

speed of the process

taking

corrective actions to recover

from the safety violation

This last

response is the most sophisticated and is suggestive of an intelligent machine

performing some advanced strategy, This kind of response is applicable to a

variety of possible mishaps, not necessarily confined to safety issues, and is

called error detection and recovery (Section 3.2.3).

Sensors

for safety monitoring range from very simple devices to highly sophisticated

systems. The topic of sensor technology is discussed in Chapter 5 (Section

5.1). The following list suggests some of the possible sensors and their

applications for safety monitoring:

Limit

switches to detect proper positioning of a part in a workholding device so that

the processing cycle can begin.

Photoelectric

sensors triggered by the interruption of a light beam; this could be used to

indicate that a part is in the proper position or to detect the presence of a

human intruder into the work cell.

Temperature

sensors to indicate that a metal workpart is hot enough to proceed with a hot

forging operation. If the workpart is not sufficiently heated, then the metal's

duetutty may be too low, and the forging dies might be damaged during the

operation.

Heat or smoke

detectors to sense fire hazards.

Pressuresensitive floor pads to detect human

intruders into the work celL

Machine vision systems to supervise

the automated system and its surroundings.

It should

be mentioned that a given safety monitoring system is limited in its ability to

respond to hazardous conditions by the possible irregularities that have been

foreseen by the system designer. If the designer h as not anticipated a

particular hazard, and consequently has not provided the system with the

sensing capability to detect that hazard, then the safety monitoring system

cannot recognize the event if and when it occurs.

Maintenance and Repair Diagnostics

Modem

automated production systems are becoming increasingly complex and

sophisticated, thus complicating the problem of maintaining and repairing them.

Maintenance and repair diagnostics refers to the capabilities of an automated

system to assist in the identi fication of the source of potential or actual

malfunctions and failures of the system. Three. modes of operation are typical

of a modern maintenance and repair diagnostics subsystem

SWills monitoring, In the statu, monitoring mode, the

diagnostic subsystem moniton and records the status of key sensors and

parameters of the system during norma. operation. On request, the diagnostics

subsystem can display any of these values and provide an interpretation of

current system status, perhaps warning of an imminert failure

Failure diagnostics. The

failure diagnostics mode is invoked when a malfunction or failure oCCUTS. Its purpose is to interpret the current values of

the monitored van. ables and to analyze the recorded values preceding the

failure so that the cause of the failure can be identified

3 Recommendation of repair

proceaure.uv the third mode of operation. the subsystem provides a recommended procedure to the

repair crew as to the steps that should be taken to effect repairs. Methods for

developing the recommendations are sometimes based on the use of expert systems

in which the collective judgments of many repair experts arc pooled and

incorporated into a computer program that uses artificial intelligence

techniques.

Status

monitoring serves two important functions if"!machine diagnostics: (I)

providing information for diagnosing a current failure and (2) providing data

to predict a future malfunction or failure. first, when a failure of the

equipment has occurred, it is usually difficult for the repair crew to

determine the reason for the failure and what steps should be taken 10 make

repairs. It is often helpful to reconstruct the events leading up to the

failure. The computer is programmed to monitor and record the variables and to draw logical inferences from their

values about the reason for the malfunction, This diagnosis helps the repair

personnel make the necessary repairs and replace the appropriate components.

This is

especially helpful in electronic repairs where it is often difficult to

determine on the basis of visual inspection which components have failed

The

second function of status monitoring is to identify signs of an impending

failure, so that the affected components can be replaced before failure

actually causes the system to go down. These part replacements can be made

during the night shift or other time when the process is not operating. with

the result that the system experiences [10loss of regularoperation

Error Detection

and Reovery

In the

operation of any automated system, there are hardware malfunctions and

unexpected events that occur during operation. These events can result in

costly delays and loss of production until the problem has been corrected and

regular operation is restored. Traditionally. equipment malfunctions are

corrected by human workers, perhaps with the aid of a maintenance and repair

diagnostics suhroutine. With the increased use of computer control for

manufacturing processes, there is a trend toward using the control computer not

only to diagnose the malfunctions but also to automatically take the necessary

corrective action to restore the system to normal operation. The term error detection and recovery is used

when the computer performs these functions,

Error Detection. A,

indicated by the term. error detection lind recovery consists of two steps: (1) error detection and (2)

error recovery. The error defection step

uses the automated svstem's available sensor systems to determine when a

deviation or malfunction has occurred, correctly interpret the sensor

signal(s), and classifythe error. Design of the error detection subsystem must

begin with 11 classification of the possible errors that can occur during

system operation. The errors in a manufacturing process tend to be vcry

application specific. They must be anticipated in advance in order to select

sensors that will enable their detection

In

analyzing a given production operation, the possible errors can be classified

into one of three general categories: (1) random errors, 1'2)systematic errors.

and (3) aberrations, Random errors occur

as a result of the normal stochastic nature of the process. These errors occur

when the process is in statistical control (Section 21.1). Large variations in

part dimensions, even when the production process is in statistical control,

can cause problems in downstream operations. By detecting these deviations on a

partbypart basis, corrective action can be taken in subsequent operations, Systematic errors are those that result

from some assignable cause such as a change in raw material properties or a

drift in an equipment setting. These errors usually cause the product to

deviate from specifications so as to be unacceptable in quality terms. Finally.

the third type of error. aberrations,

results from either an equipment failure or a human mistake. Examples of

equipment failures include fracture of a mechanical shear pin, bursts in a

hydraulic line, rupture of a pressure vessel, and sudden failure of a cutting

tool. Examples of human mistakes include errors in the control program,

improper fixture setups, and substitution of the wrong raw materials,

The two

main design problems in error detection are: (1) to anticipate all of the

possible errors that can occur in a given process and (2) to specify the appropriate sensor systems and

associated interpretive software so that the system is capable of recognizing

each error. Solving the first problem requires a systematic evaluation of the

possibilities under each of the three error classifications. If the error has

not been anticipated, then the error detection subsystem cannot correctly

detect and identify it.

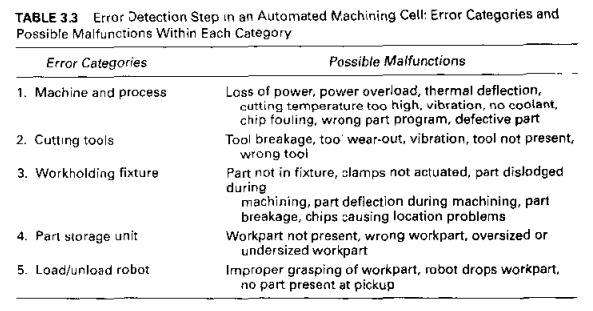

EXAMPLE 3.2 Error

Detection in an Automated Machining

Cell

Consider

an automated cell consisting of a CNC machine tool, a parts storage unit, and a

robot for loading and unloading the parts between the machine and the storage

unit. Possible errors that might affect this system can be divided into the

following categories: (1) machine and process, (2) cutting tools, (3)

workholding fixture, (4) parI storage unit, and (5) load/unload robot. Develop

a list of possible errors (deviations and malfunctions) that might be included

in each ofthcse five categories.

Solution: A list of possible errors in

the machining cell is presented in Table 3.3.

Error Recovery. Error

reCIJVPfY is

concerned with applying the necessary corrective

action to overcome the error and bring the system back to normal operation.

The problem of designing an error

recovery system focuses on devising appropriate strategies and procedures that

will either correct or compensate for the variety of errors that can occur in

the process. Generally, a specific recovery strategy and procedure must be

designed for each different error, The types of strategies can he classified as

follows:

l , Make adjustments at the end of the current

work cycle. When the current work cycle is completed. the part program

branches to a corrective action subroutine specifically

designed

for the error detected, executes the subroutine, and then returns to the work

cycle program. this action reflects a low level of urgency and is most commonly

associated with random errors in the process.

Make udjusnnents during IIII' curreW cycle. I his

general1y indicates a higher level of urgency than the preceding lype.

In this case, the action to correct or compensate for the detected error is

initiated a~ soon as the error is detected. However, it must be possible to

accomplish the designated corrective action while the work cycle is still being

executed

• Stop the prnc<'ss {O invoke corrective action. In this

case, the deviation or malfunction requires

that the execution of the work cycle be suspended during corrective action. It i~assumed that the system is

capable of automatically recovering from the error without human assistance.

Atthe end of the corrective action, the regular work cycle Is continued.

• Stop (III:process and call for help. In this

case, the error requiring stoppage of the process cannot he resolved through automated recovery procedures. This

situation arises because: (I) the automated cell is not enabled to correct the

problem or (2) the error cannot be classified into the predefined list of errors.

In either case, human assistance is required to correct the problem and restore

the system to fully automated operation.

Error

detection and recovery requires an interrupt system (Section 4.3.2). When an

error in the process is sensed and identified, an interrupt in the current

program execution is invoked to branch to the appropriate recovery subroutine,

This is done either at the end of the current cycle (type 1 above) or

immediately (types 2, 3,and 4).At the completion of the recovery procedure,

program execution reverts back to normal operation.

EXAMPLE 3.3 Error Recovery in

811Autom8ted Machining CeU

lor the automated cell uf Example 3.2. develop a

list of possible corrective actions that might be taken by the system to

address certain of the errors.

Related Topics