Chapter: Mechanical : Mechatronics : Design of Mechatronics System

A Pick and Place Robot

CASE STUDIES IN MECHATRONIC SYSTEMS:

A Pick and Place Robot:

The robot

has three axes and about these three axes only motion occurs.

The

following movements are required for this robot

Clockwise

and Anti-clockwise rotation of the robot unit on its base

Horizontal

Linear movement of the arm to extend or contraction

Up and

down movement of the arm and

Open or

close movement of the gripper

The above movements are accomplished by the use of pneumatic

cylinders operated by solenoid controlled values with limit switches.

The limit

switches are used to indicate when a motion is completed.

The clockwise rotation of the robot unit can be obtained from

a piston and cylinder arrangement during its extension and that of counter

clockwise during its retraction.

The upward and downward movement of the arm can be obtained

from a piston and cylinder arrangement during the extension and retraction of a

piston respectively.

Similarly,

the gripper can be opened or closed by the piston in a linear cylinder during

its extension.

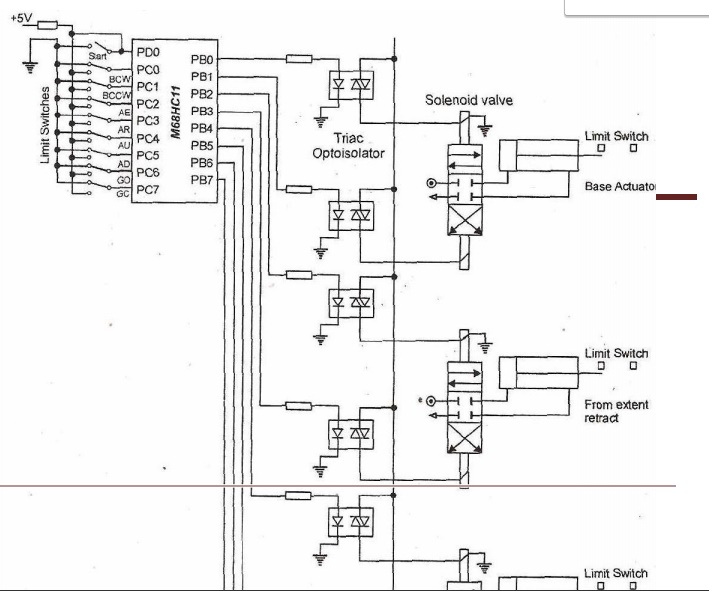

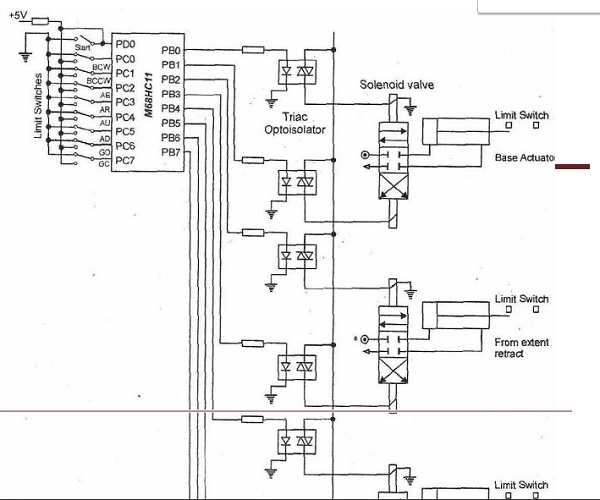

The micro controller used to control the solenoid values and

hence the movements of the robot unit. The type of microcontroller used in M68C11.

A

software program is used to control the robot.

Eight C port lies PC0 – PC7, are used to

sense the position of eight separate limit switches used for eight different

robotic movements.

Also one

line from port D is used to start or stop the robot operation.

The switch in its one position will provide +5V (a logic high

signal), to the corresponding port lines and the switch in another position

will provide 0V (a logic low

signal),

to the port lines.

So the two positions of a switch will provide either a logic

high or logic low to the corresponding PC0 – PC7, and PD,

lines.

Eight part B lines (PB0 – PB7) are used

to control eight different movement. These are Base CW, Base CEW, Arm extends,

Arm retract, Arm up, Arm down Gripper close and

Gripper

open of the robot.

PB0,

is connected to the Triacoptoisolator through a resistor.

TRIAC

isolator consists of LED and TRIAC.

For example, when the base has to rotate in clockwise

direction, a high signal is sent through line PB0

The diode is forward biased and the TRIAC optoisolation

operates, regulating the supply to the solenoid value which in turn operated

the piston rod of the pneumatic cylinder.

The base

clockwise continues the rotation till it reader the position of second limit

switch

Related Topics