Types, Manufacturing Process, Finishing Process, Properties, Uses of Rayon | Man-Made Fibres - Rayon Fibre | 11th Textiles and Dress Designing : Chapter 3 : Man-Made Fibres

Chapter: 11th Textiles and Dress Designing : Chapter 3 : Man-Made Fibres

Rayon Fibre

RAYON:

The rayon fibre is made with pure cellulose.

Cellulose is the substance which is obtained from the cell walls of the woody

part of trees and cotton plant. Cellulose is commonly used for making products

such as paper. The rayon fibre that has been formed with regenerated or

re-formed cellulose substance is called as regener-ated cellulose fibres.

Rayon is the first man -made fibre and its

production has been prophesied as long ago as 1664 by Robert Hooke, an English

naturalist. He believed that it is possible to make an “artificial glutinous”

composition which can resemble the silk-worm fibre. Man-made textile fibres

were officially recognized in 1925 when the Federal Trade Commission (FTC)

per-mitted the use of the name “rayon” from yarns obtained from cellulose or

its deriv-atives. With the increase in production of man -made fibres, FTC

ruled again in 1937 that any fibre or yarn produced chemi-cally from cellulose

must be designated as rayon.

Types of Rayon

Based on the method of manufacture, at present

there are two principal types of rayon.

1.

Rayon or Viscose

2.

High Wet Modulus Rayon (regener-ated rayon)

In High Wet Modulus Rayon (HWM), the original

material (cellulose) is changed chemically into another form, which is then

changed or regenerated into cellulose again. These changes produce the final

product that is purified cellulose in the fibre form.

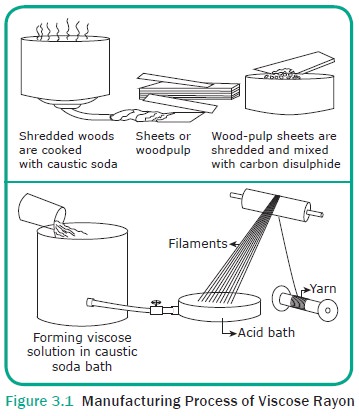

Manufacturing Process of Viscose Rayon

For making viscose rayon, wood chips or cotton

linters are treated with chemicals to produce sheets of purified cellulose that

resembles white blotters. This purified cellulose is soaked in caustic soda

which produces sheets of alkali cellulose. These sheets are then broken up into

fluffy white flakes or grains called cellulose crumbs. The crumbs are aged for

2-3 days under controlled temperature and humidity.

Liquid carbon disulphide is then added to these

cellulose crumbs which turn it into a light orange substance called cellulose

xanthate. The cellulose xanthate crumbs are then dissolved in a weak solution

of caustic soda, which turns it to a thick vis-cous solution resembling honey

in colour and consistency. This thick solution is called viscose. The viscose

is aged, fil-tered and vacuum treated to remove the air bubbles present, as

they may cause the filament to break. This treated viscose solution is then

forced through the holes of a spinneret into sulphuric acid which coagulates

the cellulose of the cellulose xanthate to form pure regenerated cellu-lose

filaments (Figure 3.1).

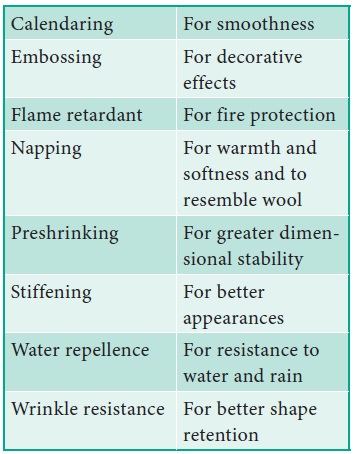

Finishing Process

A wide variety of fabrics can be produced by

viscose rayon. Spun rayon fabrics can be used for making fabrics that resem-ble

cotton, linen or wool. Rayon filament yarns can be used for making fabric that

resemble silk. Various finishes can be applied to these rayon fabrics to

improve their serviceability and to enhance their appearance. The most common

finishes given to rayon fabrics are as follows :

Properties of Rayon

Shape : Thin long filament

Size : Diameter varies from 12 to 40

microns (controlled by manufacturer)

Luster : Varies from brightness to

dullness

Strength : 2.4 – 3.0 Pa m3/kg

Elongation : 19 –

24%

Elasticity : 82%

Density : 1.5 g/cm3 for all rayon types

Moisture : Upto 10.7%

Dimensional stability : Poor

Resistance to acids : Not

good, but can be improved in special conditions

Resistance to alkalies : Not

good, but can be improved in special conditions

Sunlight : Can withstand sunlight to an

extent

Insects : Silver fish damages all type of

cellulose fibres

Reaction to heat : Can

withstand heat, but longer exposure will eventually degrade the fibre

Uses of Rayon

·

The uses of Rayon are:

·

The rayon is used to create clothing such as

blouse, jackets, sportswear and dresses.

·

It is used in textile industry for mak-ing

textile belts.

·

Rayon is used for making tyre.

·

It is also used for making carpets and surgical

dressings.

·

Rayon is used for a wide range of fabrics for

household.

Related Topics