Chapter: Physics : Advanced Engineering Materials Metallic Glasses

Modern Engineering Materials

Modern Engineering Materials

1 Introduction

2 Metallic Glasses

2.1 Glass transition temperature

2.2 Methods of production of Metallic Glasses

2.3 Types of Metallic Glasses

2.4 Properties of Metallic glasses

2.5 Applications of Metallic glasses

3 Shape Memory Alloys

3.1 Definition

3.2 Working Principle of SMA

3.3 Characteristics of SMA

3.4 Properties of Ni – Ti alloy

3.5 Advantages of SMA’s

3.6 Disadvantages of SMA’s

3.7 Applications of SMA’s

4 Nano Materials

4.1 Introduction

4.2 Definitions

4.3 Synthesis of Nanomaterials

4.4 Chemical Vapour Deposition (CVD)

5 Properties of Nanoparticles

6 Applications of Nanoparticles

7 Non linear materials (NLO materials)

7.1 Higher Harmonic Generation

7.2 Experimental Proof

7.3 Optical mixing

8 Biomaterials

8.1 Biomaterials Classifications

8.2 Conventional implant devices

8.3 Biomaterials Properties

8.4 Modern Engineering MaterialsBiomaterials

Applications

1

INTRODUCTION

There have been a number of science fields which have helps to

producing new engineering materials. Some of the fields are the nano

engineering and the forensic engineering. Hundreds and hundreds of scientists

and inventors are working and experimenting continuously to make this world a

better place to live.

These new inventions have gradually changed the course of living of

people, these New engineering materials are not a result of single engineering

technology but these are obtained or produced from a blend of different

technologies.

Some of the Modern Engineering Materials like Metallic glasses,

Shape memory alloys, Nano materials are discussed here.

2

METALLIC GLASSES

Metallic glasses are the amorphous metallic solids which have high

strength, good metallic properties and between corrosion resistance and will

possess both the properties of metals and glasses.

Example: Alloys of Fe, Ni, Al, Mn, Cu.

2.1

Glass transition temperature

It is an important parameter for the

preparation of metallic glasses. It is defined as a temperature at which the

liquid like atomic structure is obtained into a solid.

The

value of glass transition temperature for metallic alloys is about 20OC

to 30OC.

2.2

Methods of production of Metallic Glasses

Metallic glasses are manufactured by the

following methods. They are,

Twin

roller technique

Melt

extraction technique

Melt

spinning technique

Twin roller system

In this technique, the molten alloy is passed through two rollers

rotating in opposite directions.

2. Melt extraction technique

In this technique, the fast moving roller sweeps off molten droplet

into a strip from a solid rod.

3. Melt spinning technique

Principle

Quenching is a technique used to from metallic glasses. Quenching

means Rapid Cooling. Due to rapid cooling, atoms are arranged irregularly and

from metallic glasses.

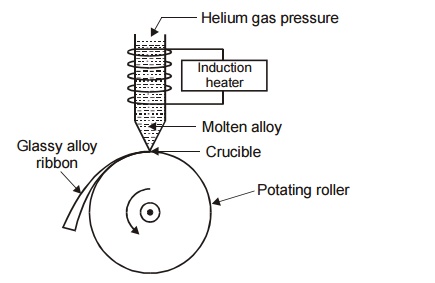

Construction

It

consists of a refractory tube with fine nozzle at the bottom. The refractory

tube is placed over the rotating roller. The roller is rotated at a higher

speed to generate a velocity of more than 50 ms 1 . An induction

heater is wounded over the refractory tube to heat the alloy to very high

temperature.

Fig. 5.1 Melt spinning technique

Working

The alloy is put into the refractory tube and induction heater is

switched on. This heats the alloy to very high temperature, hence the super

heated molten alloy ejected through the nozzle on the rotating roller and is

suddenly made to cool. The ejection rate may be increased by increasing the

inert helium gas pressure inside the refractory tube. Thus due to rapid

quenching a glassy alloy ribbon called metallic glass is formed over the

rotating roller.

2.3

Types of Metallic Glasses

The metallic glasses are classified into two

types.

Metal –

Metalloid Glasses

Example: Fe, Co, Ni – Ge, Si, B, C.

Metal –

Metal Glasses Example: Ni, Mg, Cu – Zn, Zr.

Metal – Metalloid Glasses

The first class of metallic glasses is from transition metals (Fe,

Co, Ni) Metalloid (B, Si, C & P) so they are called metal – metalloid glasses.

2. Metal – Metalloid Glasses

Nickel –

Niobium (Ni – Nb)

Magnesium

– Zinc (Mg – Zn)

Copper –

Zirconium (Cu – Zr)

Hafnium

– Vanadium (Hf – V) alloys

2.4 Properties of Metallic glasses

Metallic

glasses have very high strength and are stronger than metals because the

absence of grain boundaries and dislocations.

The

structure of metallic glass is Tetrahedral Close Packing (TCP).

These

are having very high corrosion resistance.

They

have high workability and ductility.

The

electrical resistivity is found to be high (greater than 100)/ due to this eddy

current loss is very small.

Metallic

glasses have both soft and hard magnetic properties.

These

are highly reactive and stable.

It can

also act as a catalyst.

Structural

Properties

They do

not have any crystal defects such as grain boundaries and dislocations.

They

have tetrahedral packed structure. These materials do not passes long range

anisotropy

Mechanical

Properties

Metallic

glasses are stronger than metals and alloyes because they are free from defects

and dislocations.

They

have high corrosion resistance due to random ordering.

They

have high elasticity and ductility.

Electrical

Properties

Electrical

resistivity of metallic glasses is high and it does not vary with temperature.

Eddy

current loss is very small due to high resistivity.

The Hall

co-efficient of metallic glasses is found to have both positive and negtive

signs.

Magnetic

Properties

It obeys

both soft and hard magnetic properties.

The core

losses of metallic glasses are very small.

Chemical

Properties

They

have high corrosion reistance.

They

have catalytic properties.

They are

highly reactive and stable.

2.5 Applications of Metallic glasses

Metallic

glasses are used as reinforcing elements in concrete, plastic and rubber.

Metallic

glasses are used to make pressure vessels and to construct larger fly wheels

for energy storage.

They are

used to make accurate standard resistors, Magnetic resistance sensors and

computer memories.

These

are used in tape recorder heads, cores of high power transformers and magnetic

shields.

Metallic

glasses are used as core in motors.

These

are used to make razor blades and different kinds of springs.

Metallic

glasses can be used as superconductor for producing high magnetic fields and

magnetic levitation effect.

Metallic

glasses are used to make containers for nuclear waste disposal and magnets for

fusion reactors.

Metallic

glasses are used in marine cables, chemical filters, inner surfaces of reactor

vessels, etc.,

10.Metallic glasses are very useful to make surgical

instruments.

11.Superconducting mettalic

glasses are used to produce high magnetic fields and magnetic levitation

effect.

Appendix

The

reasons for choosing metallic glasses are transformer core

Metallic glasses are available in thin sheets therefore the size

and weight of the transformer is reduced. Hysteresis loss is directly

proportional to the area of the hysteresis loop. The loop area of the metallic

glasses is very small and also has high initial permeability. So, the

hysteresis loss is almost zero… The eddy current in the core is inversely

proportional to the resistivity of the core material and directly proportional

to the thickness of the lamination of the core.

Since the resistivity of the metallic glasses is high and the

thickness of the core laminated core material due to small thickness, smaller

area, less weight, high resistivity, soft magnet with low hysteresis and eddy

current losses.

3 SHAPE

MEMORY ALLOYS

Share memory alloys (SMA’s) are metals, which exhibit two very

unique properties, pseudo-elasticity and the shape memory effect. Arne Olander

first observed these unusual properties in 1938 (Oksuta and Wayman 1998), but

not until the 1960’s were any serious research advances made in the field of

shape memory alloys. The most effective and widely used alloys include NiTi

(Nickel – Titanium), CuZnA1 and CuA1Ni.

3.1

Definition

The

ability of the metallic alloys to retain to their original shape when heating or

cooling is called as Shape Memory Alloys (SMA).

These metallic alloys exhibit plastic nature when they are cooled

to very low temperature and they return to their original nature when they are

heated. This effect is known as Shape Memory Effect.

It is also called as smart materials or intelligent materials or

Active materials. There are two types of shape memory alloys,

One way

shape memory – It returns to its memory only when heating

Two way

shape memory – It returns to its memory on both heating and Cooling.

Classification

Piezo

electric SMA materials.

Electrostrictive

SMA materials.

Magnetostrictive

SMA materials.

Thermo

elastic SMA materials.

Examples

: Ni-Ti (Nickel – Titanium), Cu

Zn A1, Cu A1 Ni, Au – Cd, Ni-Mn-Ga and Fe based alloys.

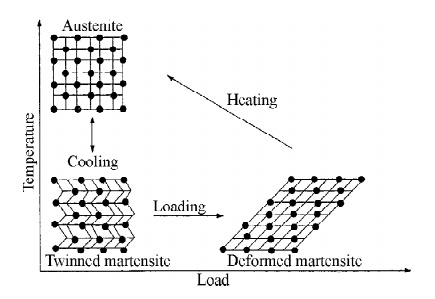

3.2 Working Principle of SMA

The shape memory effect occurs in alloys due to change in the

crystalline structure of the materials with the change in temperature and

stress.

The shape memory effect occurs between two temperature states known

as Martensite and Austenite. The Martensite structure is a low temperature

phase and is relatively soft, It has platelet structure the Austenite is a high

temperature phase and is hard it has needle like structure.

Martensite is the relatively soft and easily deformed phase of

shape memory alloys which exists at lower temperatures. It has two molecular

structures namely, twinned Martensite and deformed Martensite. Austenite is the

stronger phase of shape memory alloys which occurs at higher temperatures, the

shape of the Austenite structure is cubic.

When we apply a constant load on a shape memory alloy and cool it,

its shape changes due to produced strain. During the deformation, the

resistivity, thermal conductivity, Young’s modulus and yield strength are

decreased by more than 40%.

Twinned Martensite state alloy becomes deformed Martensite when it

is loaded. The deformed Martensite becomes Austenite when it is heated, the

Austenite transformed to original twinned Martensite state when it is cooled.

Fig.5.2 Material crystalline arrangement during

shape memory effect

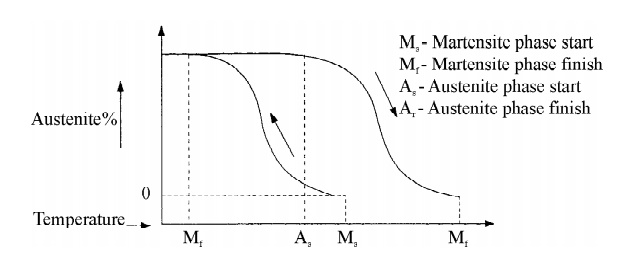

3.3

Characteristics of SMA

1. Hysteresis

Hysteresis of a SMA is defined as the difference between the

temperatures at which the material is 50% transformed to austenite when heating

and 50% transformed to martensite when cooling.

When the temperature is decreased in a metallic material, the phase

transformation takes place from austenite to martensite. This transformation

takes place not only at a single temperature, but over a range of temperatures.

The hysteresis curve for a shape memory alloy is shown below.

Fig.5.3 Hysteresis curve for

SMA’s

2. Pseudo elasticity

When a metallic material is cooled from a temperature T to a lower

temperature TC it deforms and changes its shape. On reheating the

material to Temperature (T) the shape change is received so that the material

returns to its original state. This effect is known as pseudo elasticity or

thermo elastic property.

3. Super elasticity

Super elasticity is a property of SMA. When a material is deformed

at a temperature slightly greater than its transformation temperature super

elasticity property appears (Rubber like property).

3.4

Properties of Ni – Ti alloy

Ni – Ti is a compound of Nickel and Titanium and it finds many

applications in the field of engineering due to the following properties.

It has

greater shape memory strain.

It has

more thermal stability and excellent corrosion resistance.

It has

higher ductility and more stable transformation temperatures.

It has

better bio-compatibility and it can be electrically heated.

3.5 Advantages of SMA’s

They

ahve good bio-Compatibility.

They

have simplicity, Compactness and high safety mechanism.

They

have good mechanical properties and strong corrosion-resistance.

They

have high power and weigh ratio.

3.6 Disadvantages of SMA’s

They

have poor fatigue properties.

They are

expensive and difficult to preparing in a machine.

They

have low energy efficiency.

They

have limited band with due to heating (or) cooling.

3.7 Applications of SMA’s

Eye glass frames : We know that the recently manufactured eye

glass frames can be bent back and

forth and can retain its original shape within fraction of time.

Toys : We might have seen toys such as butterflies, snakes etc., which are movable and flexible.

Helicopter blades: The life time of helicopter blades depends on

vibrations and their return to its

original shape. Hence shape memory alloys are used in helicopter blades.

Coffee Valves : Used to release the hot milk and the

ingredients at a certain temperature

Medical Applications of SMA’s

It is

used as Micro – Surgical instruments.

It is

used as dental arch wires.

It is

used as flow control devices.

It is

used as ortho – dentil implants.

It is

used for repairing of bones.

They are

used to correct the irregularities in teeth.

Engineering Applications of SMA’s

It is

used as a thermostat valve in cooling system.

It is

used as a sealing plug for high pressure.

It is

used as a fire safety valve.

It is

used for cryofit hydraulic pipe couplings.

It is

used for eye glass frame, toys, liquid safety valve.

It is

used to make microsurgical instruments, orthopedic implants.

It is

used as blood clot filter and for fracture pulling.

It is

used to make antenna wires in cell phones.

It can

be used as circuit edge connector.

4 NANO MATERIALS

4.1

Introduction

Nanomaterials (nanocrystalline materials) are materials possessing

grain sizes of the order of a billionth of a meter. They manifest extremely

fascinating and useful properties, which can be exploited for a variety of

structural and non structural applications.

All materials are composed of grains, which in turn comprise many

atoms. These grains are usually invisible to the naked eye, depending on their

size. Conventional materials have grains varying in size anywhere from 100’s of

microns ( m ) to millimeters (mm). A micron ( m ) is a micrometer or a

millionth (10–6) of a meter. An average human hair is about 100 m in

diameter. A nanometer (nm) is even smaller a dimension than a m and is a

billionth (10–9) of a meter. A nanocrystalline material has grains

on the order of 1-100 nm. The average size of an atom is on the order of 1 to angstroms

( Ao ) in radius.

nanometer comprises 10 Ao , and

hence in one nm, there may be 3-5 atoms, depending on the atomic radii.

Nanocrystalline materials are exceptionally strong, hard, and ductile at high

temperatures, wear-resistant, corrosion-resistant, and chemically very active.

Nanocrystalline materials, or Nanomaterials, are also much more formable than

their conventional, commercially available counterparts.

4.2

Definitions

Nanotechnology

Nanotechnology

is a field of applied science and technology which deals with the matter on the

atomic and molecular scale, normally 1 to 100 nanometers, and the fabrication

of devices with critical dimensions that lie within that size range.

Nanomaterials

Nano materials are the materials with grain sizes of the order of

nano meter (10 9 m) i.e., (1-100 nm). It may be a metal,

alloy, inter metallic (or) ceramic.

Nanomaterials are the materials with atoms

arranged in nano sized clusters which become the building block of the

material. Any Material with a size between 1 and 100 nm [ 10 9 m to 10 7 m] is also called

Nanomaterials.

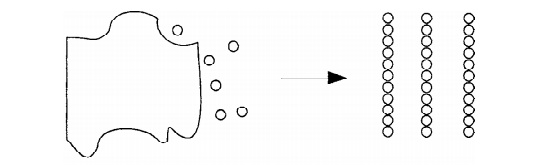

4.3

Synthesis of Nanomaterials

The Nano mateirals can be synthesized by two

processes, they are

Top –

down approach

Bottom –

up approach

1. Top – down approach

The removal or division of bulk material or the miniaturization of

bulk fabrication processes to produce the desired nanostructure is known as

top-down approach. It is the process of breaking down bulk material to Nano

size.

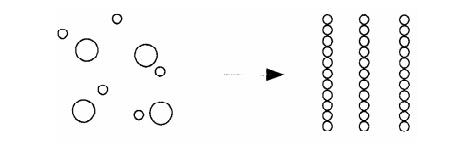

Fig.5.4 Synthesis of

Nanomaterials for Top – down approach

Types of

Top – down Methods

Milling

Lithographic

Machining

Bottom – up approach

Molecules and even nano particles can be used as the building block

for producing complex nanostructures. This is known as Bottom – up approach.

The Nano particles are made by building atom by atom.

Fig.5.5 Synthesis of

Nanomaterials for Bottom – up approach

Types of

Bottom up Methods

Vapour

phase deposition Method

Molecular

beam epitaxy Method

Plasma

assisted deposition Method

Metal

Organic Vapour Phase Epitaxy [MOVPE]

Liquid

phase process [Colloidal method and Sol – Gel method]

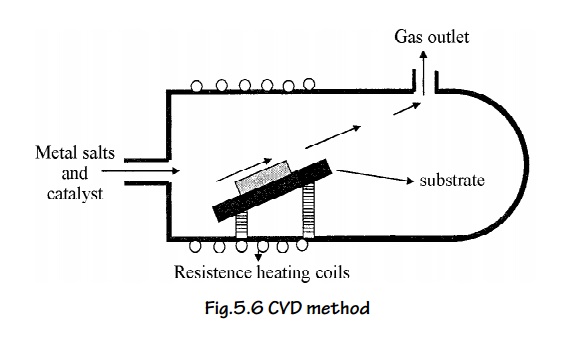

4.4

Chemical Vapour Deposition (CVD)

It is method in which the reaction or thermal decomposition of gas

phase species at higher temperatures [500 – 1000OC] and then

deposition on a substrate takes place, in CVD method carbon nanotubes are grown

from the decomposition of hydrocarbons at temperature range of 500 to 1200OC.

In this process, the substrate is placed inside a reactor to which a number of

gases are supplied. The fundamental principle of the process is that a chemical

reaction takes place between the source gases. The produce of that reaction is

a solid material with condenses on all surfaces inside the reactor.

Fig.5.6 CVD method

Example of CVD technique

An aerosol spray pyrolysis (Pyrolysis is the chemical decomposition

of organic materials by heating in the absence of oxygen or any other reagents)

is the example of CVD technique, in which high aqueous metal salts are sprayed

in the form of fine mist and then passed into a hot flow tube. In the hot flow

tube pyrolysis converts the salts into the final products on the substrate, in

this method the materials are mixed in a solution, homogeneous mixing is

obtained to the atomic level. They pyrolysis at low temperature gives the

particles in the size range 5 – 500 nm, in this CVD method catalysts are used

for better chemical reactions, when the catalyst is in nanosize, dispersion of

particles is happened due to templating effect. In the Production of carbon

nanotubes using the decomposition of ethane with hydrogen, Fe, Co or Ni based

catalysts are used. The size and distribution of the catalyst particles

determine the internal diameter of the nanotubes.

5

PROPERTIES OF NANOPARTICLES

A Bulk materials is reduced to a nano size, the

following changes are occurred

Large

fraction of surface atoms

High

surface energy

Spatial

confinement

Reduced

imperfections

The surface area effects, quantum effects can begin to dominate the

properties of matter as size is reduced to the nano scale. These can affect the

optical, electrical and magnetic behavior of materials.

Due to their small dimensions, nano materials have extremely large

surface area to volume ratio, which makes a large fraction of atoms of the

materials to be the surface or interfacial atoms, resulting in more “surface”

dependent material properties.

When the size of their structural components decreases, there is

much greater interface area within the material this can greatly affect both

mechanical and electrical properties, ie., the interface area within the

material greatly increases, which increases its strength. Reduced imperfections

are also an important factor in determination of the properties of the nano

materials

1. Electrical Properties of Nanomaterials

Nanomaterials can store more electrical energy than the bulk

material, because of their large grain boundary (surface) area.

The energy band structure and charge carried density in the nano

materials can be modified quite differently form their bulk size in turn will

modify the electronic properties of the materials.

In nano size an optical absorption band can be introduced, or an

existing band can be altered by the passage of current or by the application of

an electric field.

2. Optical Properties of Nanomaterials

The quantum confinement of electrical carriers within nanoparticles

makes efficient energy and charge transfer over nanoscale distances in nano

devices.

The linear and nonlinear optical properties of nanomaterials can be

finely modified by controlling the crystal dimensions

The color of nanomaterials is changed when the surface plasmon size

is reduced. A surface plasmon is a natural oscillation of the electron gas

inside a given nano sphere.

3. Chemical Properties of Nanomaterials

The increased surface area of nano particle increases the chemical

activity of the material. Metallic nanoparticles can be used as very active

catalysts. Chemical sensors from nanoparticles and nano wires enhanced the

sensitivity and sensor selectivity

4. Mechanical Properties of Nanomaterials

The mechanical properties such as hardness and elastic modulus,

fracture toughness, scratch resistance, fatigue strength, tensile strength,

strain-to-failure, Young’s modulus, impact strength and increased at the nanometer

scale

Energy dissipation, mechanical coupling and mechanical

nonlinearities are also influenced at the nanometer scale.

The strength of the material at nanosize approaching the

theoretical limit due to the absence of internal Structural imperfections such

as dislocations, micro twins, and impurities.

5. Magnetic Properties of Nanomaterials

The strength of a magnet is measured in terms of coercivity and

saturation magnetization values. These values increase with a decrease in the

grain size and an increase in the specific surface area (surface area per unit

volume) of the grains.

6. Thermal Properties of Nanomaterials

Photon transport within the materials will be changed significantly

due the photon confinement and quantization of photon transport, resulting in

modified thermal properties. For example, nano wires from silicon have a much

smaller thermal conductivities compared to bulk silicon.

The nanomaterials structures with high interfaces densities would

reduce the thermal conductivity of the materials. There are several effects

being considered for the reduction of thermal conductivities: interfacial

roughness, phonon band gaps, dispersion mismatch, doping, structural defects,

processing conditions, etc.

6

APPLICATIONS OF NANOPARTICLES

Though

nano – particles are very small, they are the important materials to built

future world. They have applications almost in all engineering fields as

follows Mechanical Engineering

Since

they are stronger, lighter etc., they are used to make hard metals.

Smart

magnetic fluids are used in vacuum seals, magnetic separators etc.

They are

also used in Giant Magneto Resistant (GMR) spin valves.

Nano-

MEMS (Micro-Electro Mechanical Systems) are used in ICs, optical switches,

pressure sensors, mass sensors etc.

Electrical, Electronics and Communication

Engineering

Orderly

assembled nanomaterials are used as quantum electronic devices and photonic

crystals.

Some of

the nanomaterials are used as sensing elements. Especially the molecular

nanomaterials are used to design the robots, assemblers etc.

They are

used in energy storage devices such as hydrogen storage devices, magnetic

refrigeration and in ionic batteries.

Dispersed

nanomaterials are used in magnetic recording devices, rocket propellant, solar

cells, fuel cells, etc.

Recently

nano-robots were designed, which are used to remove the damaged cancer cells

and also to modify the neutron network in human body.

Computer Science Engineering and IT

Nano-materials

are used to make CD’s and semiconductor laser.

These

materials are used to store the information in smaller chips.

They are

used in mobiles, lap – tops etc

Further

they are used in chemical / Optical computers.

Nano –

dimensional photonic crystals and quantum electronic devices plays a vital role

in the recently developed computers.

Bio–Medical and Chemical Engineering

Consolidated

state nanoparticles are used as catalyst, electrodes in solar and fuel cells.

Bio-sensitive

nanoparticles are used in the production of DNA –chips, bio-sensors etc.

Nano-structed

ceramic materials are used in synthetic bones.

Few

nanomaterials are also used in adsorbents, self –cleaning glass, fuel

additives, drugs, ferrofluids, paints etc.

Nano

–metallic colloids are used as film precursors.

7 NON

LINEAR MATERIALS (NLO MATERIALS)

The change in optical properties due to electrical and magnetic

field associated with light is called non linear effects and those materials

which possess these effects are those materials possess these effects are

called non-linear materials.

Example:

Lithium

tantalate

Lithium

iodate (LiO3)

Barium

Sodum niobate

Ammonium-dihydrophosphate

(ADO)

Potassium-dyhydrophosphate

(KDP)

7.1

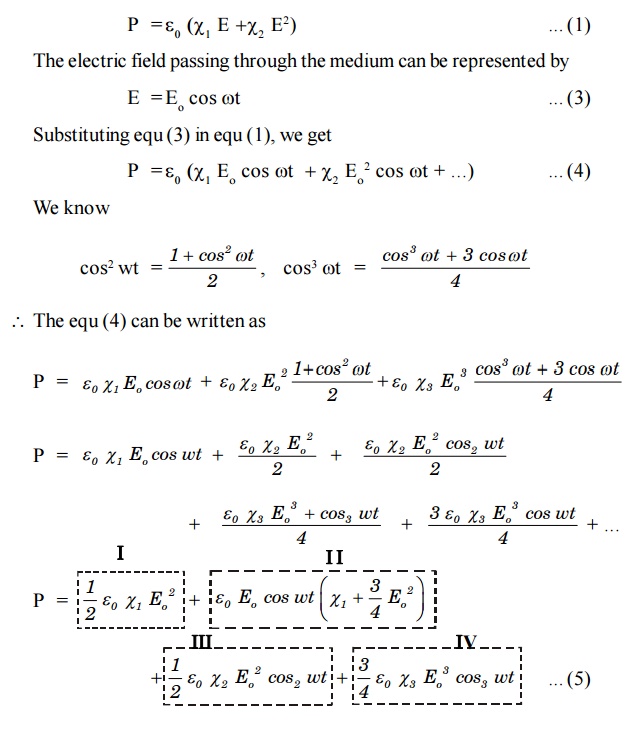

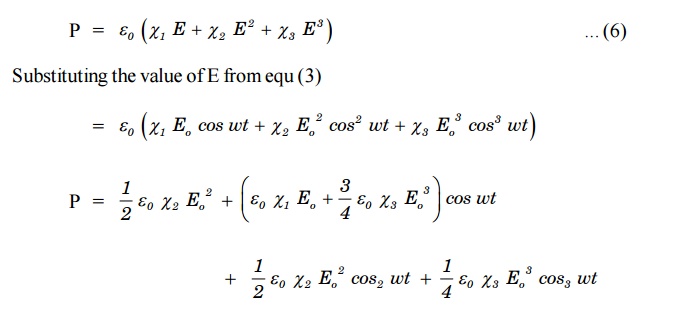

Higher Harmonic Generation

Higher (second) Harmonic generation represents the generation of

new frequencies with the help of the crystals such as quartz, LiO3,

etc.

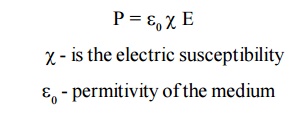

Explanation

In a

linear medium, Polarization (P) is proportional to the electric field E that

induces it

When light of higher intensity is passed through dielectric medium,

the electric field has larges amplitude and the oscillation of dipoles are

distorted. Therefore, some nonlinearity is observed beteen P and E and hence

the higher fields are written as

with increase of higher order terms come into play. Let us assume that the field is strong enough to give rise to χ2.

This non linear polarization shows that it contains the second

harmonic of (III term) as well as an average term (I term) called optical

rectification. It can be shown that only in the crystals lacking inversion

symmetry, second harmonic generation (SHG) is possible.

7.2

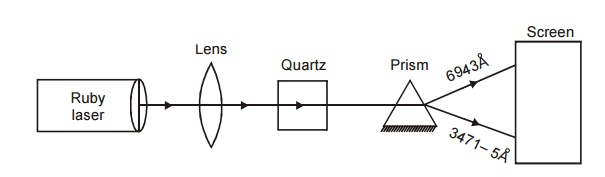

Experimental Proof

When the fundamental radiation from a laser is sent through SHG

crystal, due to SHG, conversion to double the frequency ie. half the wave

length takes place. For example 1.064 m radiation from Nd-YAG laser gets

converted to 0.532 m on passing through crystals like KDP, ADP, etc.

Fig. 5.7 Experiment

arrangement for SHG

If the incident radiation from the laser is intense enough such

that the polarization needs to be represented by three terms.

The last term in the above equation represents third harmonic generation at frequency 3ω . Likewise one can account for higher harmonic generation.

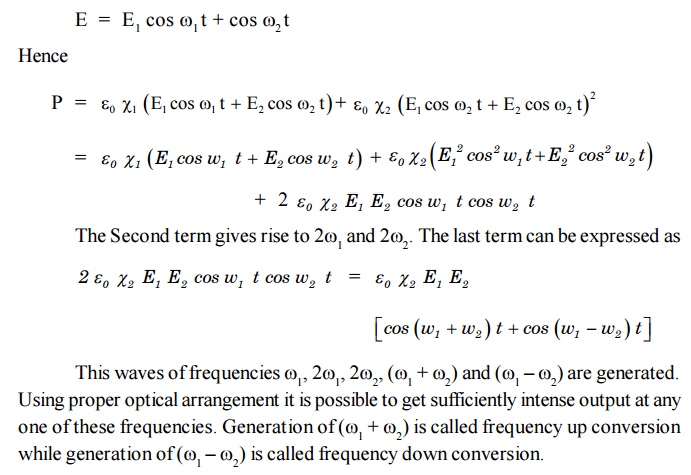

7.3

Optical mixing

We are familiar with ariving at a new colour by mixing of two

colours in paints using non linear phenomena, called optical mixing, generation

new frequencies are possible. Suppose two coherent waves of unequal frequencies

1 and 2 are traversing the material, then

8

BIOMATERIALS

Biomaterials are used to make devices to replace a part or a

function of the body in safe, reliably economically, and physiologically

acceptable manner. A variety of devices and materials are used in the treatment

of disease or injury. Commonplace examples include suture needles, plates,

teeth fillings, etc. (or)

A biomaterial is a synthetic material used to replace part of a

living system or to function in intimate contact with living tissue of a human

body. Alone or as part of a complex system, is used to direct, by control of interactions

with components of living systems, the course of any therapeutic or diagnostic

procedure.

8.1

Biomaterials Classifications

When a synthetic material is placed within the human body, tissue

reacts towards the implant in a variety of ways depending on the material type.

The mechanism of tissue interaction depends on the tissue response to the

implant surface. In general, there are three terms in which a biomaterial may

be described in or classified into representing the tissues responses. These are

bioinert, bioresorbable, and bioactive.

1. Bioinert Biomaterials

The term bioinert refers to any material that once placed in the

human body has minimal interaction with its surrounding tissue. Examples of

these are stainless steel, titanium, alumina, partially stabilised zirconia,

and ultra high molecular weight polyethylene. Generally a fibrous capsule might

form around bioinert implants hence its bio functionality relies on tissue

integration through the implant.

2. Bioactive Biomaterials

Bioactive refers to a material, which upon being placed within the

human body interacts with the surrounding bone and in some cases, even soft

tissue. This occurs through a time - dependent kinetic modification of the

surface, triggered by their implantation within the living bone. An ion -

exchange reaction between the bioactive implant and surrounding body fluids -

results in the formation of a biologically active carbonate apatite (CHAp)

layer on the implant that is chemically and crystallographically equivalent to

the mineral phase in bone. Prime examples of these materials are synthetic

hydroxyapatite [Ca10 (PO4)6(OH)2],

glass ceramic A-W and bioglass.

3. Bioresorbable Biomaterials

Bioresorbable refers to a material that upon placement within the

human body starts to dissolve (resorbed) and slowly replaced by advancing

tissue (such as bone). Common examples of bioresorbable materials are

tricalcium phosphate [Ca3 (PO4)2] and

polylactic-polyglycolic acid copolymers. Calcium oxide, calcium carbonate and

gypsum are other common materials that have been utilised during the last three

decades.

8.2

Conventional implant devices

1. Ceramics

Inorganic compounds that contain metallic and non-metallic elements,

for which inter-atomic bonding is ionic or covalent, and which are generally

formed at high temperatures.

Example:

aluminum oxide, zirconia, calcium phosphates.

Uses of Ceramics

Structural

components

Joint

replacements, hip and knee

Spinal fusion

devices

Dental

crowns, bridges, implants, ect

Other

applications

Inner

ear and cochlear implants

Tissue

engineering

Coatings

for heart valves

Metals

Materials containing only metallic atoms either as single elements

or in combination in a closely packed crystal structure.

Example: stainless steel, cobalt alloys, titanium alloys.

Uses of Metals

Structural

components

Joint

replacements

Bone

fracture pins, plates

Dental

implants

Other

applications

Leads,

wires, tubing

Cardiac

devices

Polymers

From Greek - 'poly' meaning many and 'mer' meaning unit or part Low

density structures of non-metallic elements Often in the form of macromolecules

- chains, branched chains or cross linked networks Poor thermal and electrical

conductors due to the affinity of the elements to attract or share valence

electrons

Example:

Silicones, poly (ethylene), poly (vinyl

chloride), polyurethanes, polylactides

Uses of Polymers

Many

applications

Valves,

ducts, catheters

Joint

replacement

Coatings,

encapsulates

Tissue

engineering scaffolds

8.3 Biomaterials Properties

Mechanical

properties of the various tissues in the human body are well established, and

it is important that the in-vivo environment of an implant be considered during

implant design. Mechanical performance of an implanted device is influenced by

the inherent properties of the chosen biomaterial grades and by the processing

method used to convert them into their finished forms.

Degradation

properties of chosen biomaterials can play a pivotal role in determining tissue

healing dynamics and thus clinical outcome. Timescales involved in the tissue

regeneration process are increasingly well understood. Through transferring

functional requirement back to the native tissue during its regeneration,

clinically superior results may be achieved. Furthermore, resorption of the

implant can reduce both lifetime procedural cost and incidence of

post-operative complications.

Surface

properties of a biomaterial, determined by both its chemical composition and

conversion processes, affect the local tissue response at the

biomaterial-tissue interface on a cellular level. Consideration is therefore

given to the desired cellular response to a biomaterial surface, during medical

implant design.

8.4

Biomaterials Applications

Drug delivery

Cancer

detection, therapy and prevention.

Biomaterial-cell

interactions in applications such as tissue engineering, advanced stem-cell

culture, biosensors, and targeted drug delivery via the blood.

Advanced

drug delivery, ranging from polymeric aerosols that carry life-saving drugs to

cationic polymer/DNA self-assembled nanocomplexes that deliver DNA to specific

tissues for in vivo gene therapy.

Genetically-engineered

polymers for tissue engineering and drug delivery applications.

Cellular

biopolymers and their role in cell migration and cancer metastasis.

Other important applications

Heart-

pacemaker, artificial valve, artificial heart

Eye

-contact lens, intraocular lens

Ear

-artificial stapes, cochlea implant

Bone

-bone plate, intramedullary rod, joint prosthesis, bone cement, bone defect

repair

Kidney-

dialysis machine

Bladder-

catheter and stent

Muscle

sutures- muscle stimulator

Circulation-

artificial blood vessels

Skin

burn- dressings, artificial skin

Endocrine

-encapsulated pancreatic islet cells.

Related Topics