Textiles and Dress Designing - Method of Pattern Making | 11th Textiles and Dress Designing : Chapter 10 : Patterns

Chapter: 11th Textiles and Dress Designing : Chapter 10 : Patterns

Method of Pattern Making

METHOD OF PATTERN MAKING

Pattern making is art to learn and should be

followed carefully. Pattern can be made by three main methods namely

·

Drafting method

·

Draping method

·

Commercial patterns

Drafting Method

Drafting is the system of drawing patterns on

paper with mechanical precision on the basis of body measurements. A basic

pattern should have a minimum number of darts and should fit the body

comfortably without being tight or loose. Drafting can be done on ordinary

brown paper which is not too thin. It can be done on thicker paper to be

preserved for future use. Sometimes this is made on card board and used for

many years. A sharp pencil, ruler, ‘L’ scale or set squares are needed to make

a pattern with straight lines and smooth curves. The fol-lowing principles

should be understood before starting to attempt drafting. This method is easy

but requires some calcu-lation. Drafting has a set of instructions like “Draw a

line AB measuring half waist round” which has to be followed to get the paper

pattern (Figure 10.6).

Important Points to Remember while Drafting Patterns

·

Patterns should be made larger than the body size

by adding ease allowance to the actual measurement. This gives the garment

freedom of movement, ease, and comfort in wearing. Normally 5 cm allowance is

given around the chest and 1 to 2.5 cm for other measurements.

·

For identical designs where the right and left

side of the garment are same, only one side is needed to be made in paper. It

can be reserved and copied for the opposite side.

·

It is better to draft the basic pattern block

first then while cutting, seam allowances should be added to the pattern and

markings should be made on the fabric.

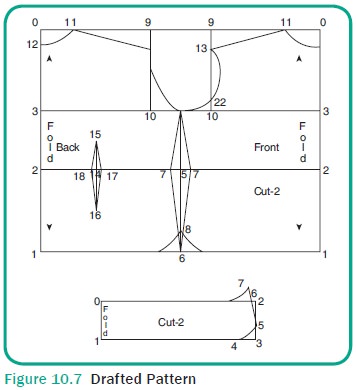

The following construction detailed infor-mation

should be recorded and marked clearly (Figure 10.7).

a.

Name of each piece of pattern.

b.

Number of pieces to be cut with each pattern

piece.

c.

If seam allowance is included in the draft. Seam

lines and cutting lines should be clearly shown using blue and red pencil

respectively.

d.

Straight grain or lengthwise line should be drawn

on all patterns with a red pencil as shown (← →). This line indicates the

direction in which the pattern has to be kept on the cloth so that it is

parallel to the selvedge.

e.

Matching notches or balance marks should be

provided along seams to show which seams are to be joined together.

f.

It is advantageous to cut outward notches at

centre front and centre back of pattern pieces as it helps at the time of

assembling the garment and stitching collars.

g.

Folding lines, dart marking, pleat markings etc.

should be clearly shown.

h.

Draping technique can be mastered by carefully

following the instruc-tion and drawing the patterns in a systematic manner.

Draping Method

Toils and modeling are another common terms used

to describe draping. Draping is the manipulation of fabric on a three

dimensional form by a designer to obtain perfect fit and harmony between the

fab-rics and design of the garment and the sil-houette of the individual. The

material is modeled around a dress stand or human body to see the fit. It is

checked, marked and then cut and finally stitched. There are several types of

dress forms available in the market but the most commonly used ones are:

·

Adhesive Paper Dress Form

·

Muslin Padded Dress Form

·

Paper Mache or Plastic Molded Dress Forms

Adhesive Paper Dress Form

Adhesive paper dress forms are pre-pared for

individual body measurements by pasting adhesive tapes over a correct fitting

garment (Bannian) worn by the individual. The centre front, back, neck armscye,

waist and hip lines are marked. The adhesive form is cut through care-fully

without hurting the individual and rejoined and the edges are finished neatly

with help of adhesive tapes. The dress form should be allowed to dry completely

before use (Figure 10.8).

Muslin Padded Dress Form

Muslin padded dress forms are similar to adhesive

paper dress forms but they are made with muslin materials. The inner side of

the dress form is padded, hence its stiffer. Padding helps to increase the

usage and life of the dress form. This can be placed on a stand while draping

and preparing the paper patterns. Later it is covered with a neat fabric and

used when needed (Figure 10.9).

Paper Mache or Plastic Molded Dress Forms

Paper mache or plastic molded dress forms are

commercially made and sold for standard sizes. Even separate hand, leg dress

form are available. It is costly but can be used for many years. These dress

forms will not suit individual with figure irregularities (Figure 10.10).

Draping Method

The method of preparing a pattern fol-lowing

draping method is discussed below (Figure 10.11):

·

Place the dress form on to a stand or table and

ensure it is steady.

·

Select the fabric, which has to be cut and

stitched. Drape the fabric on the individual, look of design and colour to

match the individual’s structure and complexion.

·

Beginners can first drape with fabric which is of

similar texture and weight to the fabric, which is to be cut and sewed.

·

Drape the fabric on the dress form allow it to

fall naturally. Check the grain of the fabric (lengthwise grain should match

the centre front line). A number of experimental folds have to be made. Check

for best design and drape. Pin the extra fabric. Do not cut.

·

Ensure the design and drape once again, so as to

avoid cutting on wrong size or designs.

·

Draping should be done on a continu-ous line to

give the best effect. This is possible only through practice. Hence before

finalizing the design and pat-tern try draping in a number of ways.

·

Special care should be taken in case of checks

and stripes. These fabrics can be draped on cross grain also for cre-ating

design variation, especially for yoke or collar.

·

To decide on fullness, try 2 to 3 styles.

Example, pin tucks, box pleats and gathers can be draped on the dress form and

the best can be selected.

·

Once the design of the garment is final-ized pin

the fabric on the dress form, match the centre front, back, shoulder, chest

round lines to that in the dress form. Pin along the line.

·

Move the fingers slowly and make the dart and

fullness needed and pin it. Care should be taken to maintain grain.

·

Mark the line, cut and keep the pieces ready for

sewing.

·

Name the pieces to avoid confussion. Fold the

piece and keep them in a neat cover, if stitching is not being done

immediately.

·

For identical design one side can be draped,

marked and cut. The reverse of the cut patterns can be used for pre-paring the

pattern for the other side.

·

Care should be taken to use minimum or fine pins

especially for delicate fab-rics like silk.

·

Based upon the type of design, dart can be

converted to create fullness.

·

Place weights or tape while draping design which

requires more quantity of fabric. Examples: Wide neckline or side panels which

are cut and gathered. Since the fabric drops down, weights can be placed inside

these drapes or tapes should be used.

·

Trimming, buttons and other accesso-ries can be

placed on draped fabrics to check its suitability with the fabric.

In spite of the cost, the method helps one to

view the look of the finished garment; hence correction can be made even before

cutting the patterns. It also involves more time and practices.

Commercial Patterns

Commercial patterns were first developed in

U.S.A. in 1950’s. Later patterns were developed for all age groups of both

sexes. Commercial paper is made out of tissue butter papers for standard body

mea-surements. Generally these patterns are marked for 5 sizes and packed in an

enve-lope. Commercial patterns are produced by companies and sold. It is very

popular in foreign countries. The pattern names, num-ber of pieces to be cut,

grain, notches, cut-ting lines, stitching lines, darts and fullness are also

marked. On the cover, a picture of the dress is shown. The size, cutting,

sewing instructions are also mentioned. The body measurements are mentioned on

the cover. This helps one to select the correct size. Dress modifications are

given by some com-panies. The materials required, like buttons and accessories

are also printed on the cover.

The major advantages of commer-cial patterns are

good designs, with simple instructions. The pattern will have good fit when

compared to other patterns but will need modification in case of irregular body

structures. In India commercial pat-terns are not popular.

Related Topics