Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Automotion and Control Technologies

Levels of Automation

LEVELS

OF AUTOMATION

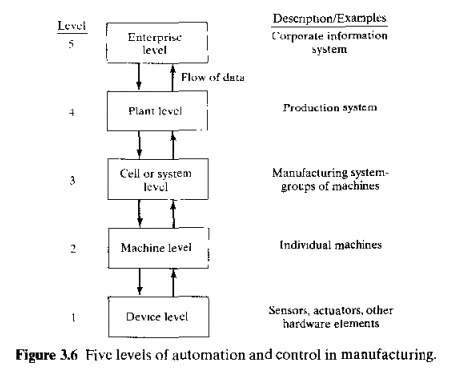

The

concept of automated systems can be applied to various levels of factory

operations. One normally associates automation with the individual production

machines. However, the production machine itself 1~made up of subsystems that

may themselves be automated. For example. one of tile important automation

technologies we discuss in this pari of the book isnumcrical control

(Chapter6).A modern numerical control (NC) machine tool is an automated system.

However, the NC machine itself is composed of multiple control systems. Any NC machine has at least two axes of

motion, and some machines have up to five axes. Each of these axes operates as

a positioning system, as described in Section 3.1.3, and is, in effect, itself

an automated system. Similarly, a NC machine is often part of a larger

manufacturing system, and the larger system may itself be automated. For

example, two or three machine tools may be connected by an automated pact

handling system operating under computer control. The machine tools also

receive instructions (e.g., part programs) from the computer. Thus we have

three levels of automation and control included here (the positioning system

level, the machine toollevel, and the manufacturing system level). For our purposes

in this text, we can identify five possible levels of automation in a

production plant. They are defined next, and their hierarchy is depicted in

Figure 3.6.

Device level. This is the lowest level in our

automation hierarchy. It includes the actuators, sensors, and other hardware

components that comprise the machine level. The devices are combined into the

individual control loops of the machine; for ex· ample, the feedback control

loop for one axis of a CNC machine or one joint of an industrial robot.

Machine [ewl. Hardware

at the device level is assembled into individual machines. Examples include CNC

machine tools and similar production equipment, industrial roo bOIS, powered

conveyors, and automated guided vehicles. Control functions at this

level

include performing the sequence of steps in the program of instructions in the

correct order and making sure that each step is properly executed.

Cell or system level. This is

the manufacturing cell or system level, which operates under instructions from the plant level. A manufacturing cell or system is

a group of machines or workstations connected and supported by a material

handling system, computer. and other equipment appropriate to the manufacturing

process. Production lines arc included in this level. functions include part

dispatching and machine loading. coordination among machines and material

handling system, and collecting and cvaluatinginspection data.

Plum level. This is the factory or production

systems level. It receives instructions from

(he

corporate iuforrnation system and translates them into operational plans for

production. Likely functions include: order processing, process planning,

inven. tory control, purchasing, material requirements planning, shop floor

control, and qualiry control.

Enterprise level. This is

the highest level.consisting of the corporate information systern.It is

concerned with all of the functions necessary to manage the company: marketing

and sales, accounting, design, research, aggregate planning, and master

production scheduling.

Most of

the technologies discussed in this part of the book are at level 2 (the machine

level), although we discuss level! automation technologies (the devices that

make up a control system) in Chapter 5. The level 2 technologies include the

individual controllers (e.g .. programmable logic controllers and digital

computer controllersj.numerical controt machines. and industrial robots. The

material handling equipment discussed in Part 11 abo represent technologies at

level 2. although some of the handling equipment are themselves sophisticated

automated systems. The automation and control issues at Jevel2 aTCconcerned with the basic operation of the equipment and the physical processes they

perform

Controllers.

machines, and material handling equipment are combined into manufacturing

cells. or production lines. or similar systems, which make up level 3,

considered in Part III. A manufacturing

system is defined in this book as a collection of integrated equipment

designed for some special mission, such as machining a defined part family or

assembly of a certain product. Manufacturing systems also include people.

Certain highly automated manufacturing systems can operate for extended periods

of time without humans present to attend to their needs. But most manufacturing

systems include workers as important elements of the system: for example,

assembly workers on a eooveyorized production line or part loaders/unloadcrs in

a machining cell. Thus, manufacturing systems are designed with varying degrees

of automation; some are highly automated, others are completely manual, and

there is a wide range between.

The

manufacturing systems in a factory arc components of a larger system, which we

refer to as a production system. We define a production system as the people, equipment, and procedures that are

organiz.ed for the combination of materials and processes that comprise a

company's manufacturing operations. Production systems are at level 4, the

plant level, while manufacturing systems are at level 3 in our automation

hierarchy. Production systems include not only the groups of machines and

workstations in the factory but also the support procedures that make them

work. These procedures include production

control, inventory control, material requirements planning. shop floor control.

and quality control. These systems are discussed in Parts IV and V. They are

often implemented not only at the plant level but also ar the corporate level

(level S).

Related Topics