Role of Computer in Garment Industry - Types of CAD Systems | 12th Textiles and Dress Designing : Chapter 15 : Role of Computer in Garment Industry

Chapter: 12th Textiles and Dress Designing : Chapter 15 : Role of Computer in Garment Industry

Types of CAD Systems

Types of Cad Systems

·

Textile design systems

·

Knitted fabrics

·

Printed fabrics

·

Illustrations/ Sketch Pad Systems

·

Texture Mapping: 3D Draping Software

·

Embroidery systems

·

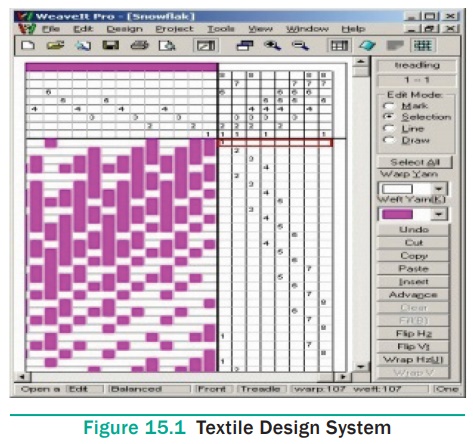

Textile Design Systems

Textile design is the process of developing designs for woven,

knitted or printed fabrics or surface ornamented

Textile designers are involved with the production of

these designs. The designs developed are then used on Textiles and clothing

materials.

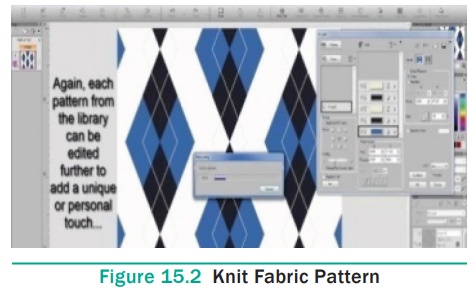

Knitted Fabrics

The specialized CAD software is also available for knitwear

design. Indication of all knit stitch formation can be viewed on the screen.

CAD program produces a pullover graph and it specifies the information on

amount of yarn needed by colour for each piece.

The other example of the new technology in the industries is using

a yarn scanner. It is attached to the computer and it scans a thousand meters

of yarn and then simulates a knitted fabric on-screen. This simulation shows

how the fabric will look when knitted using the selected yarn.

Illustrations/ Sketch Pad Systems

Sketchpad is an innovative computer program. It has graphic

programmes that allow the designer to use pen or stylus on electronic pad or

tablet. Freehand images can be created and then stored in the computer. Using

this sketchpad, a lot of different knit and weave simulations can also be

created and stored in a library. Later the stored designs can be selected and

pasted over the sketches to show texture and dimensions.

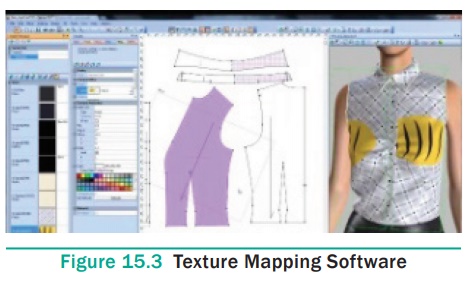

Texture Mapping : 3D Draping Software

Texture mapping is a graphic design process which shows the visual

effects of fabric on the body. In this system, the fabric can be draped over a

form in a realistic way. The designer starts with an image of a model wearing a

garment. Each section of the garment is outlined from seam line to seam line.

The swatch of a new fabric is created in the textile design system and laid

over the area. The computer automatically fills in the area with new colour.

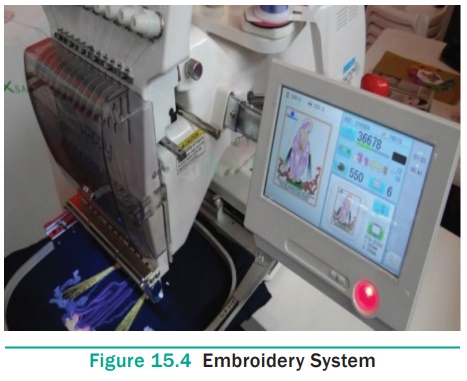

Embroidery Systems

The embroidery design software is used for mass producing the home

and commercial embroidered textiles. The designs used for embroidery can be

incorporated on the fabric for making garment. Designers can create embroidery

designs or motifs straight on the computer. Colour of the design and embroidery

stitches is defined. Several combinations of colour and stitches are possible

in this system.

Digitizing Systems

Digitizing is a process of adding details to an original pattern

or sloper in the computer. The pattern can be prepared by marking the notches,

by defining the series of selected points around the pattern. These basic

patterns can be manipulated with the help of specific tools in the computer.

For example in case of trousers, darts can be moved and pleats can be created,

also new designs can be created on screen from pre-existing pattern.

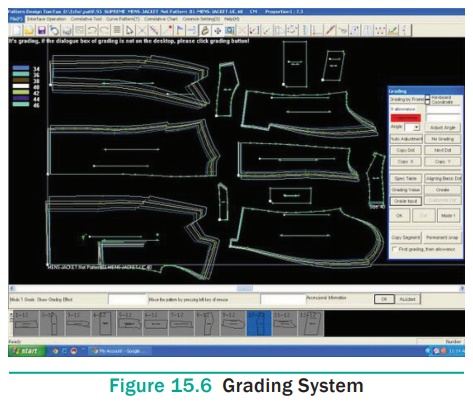

Grading Systems

Pattern grading is the process of turning base size or sample size

patterns into additional sizes using a size specification sheet or grading. It

is simply increasing or decreasing the size of patterns. Production sample

meant for approval is normally medium size but if the buyer requires different

size then the patterns are graded to Small(S), Large (L), Extra Large (XL),

Double Extra Large (XXL).

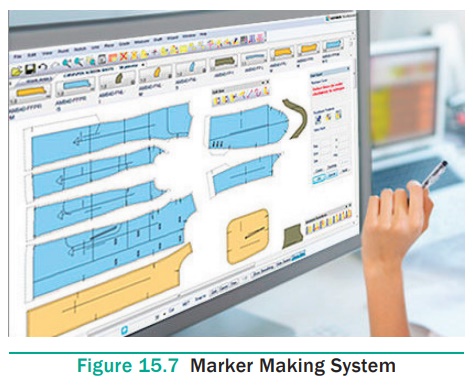

Marker Making Systems

A marker is commonly done on large thin paper. It holds all the

size of pattern pieces for a specific style of garments. Computerized method is

the best and

This method ensures minimum wastage of fabric. On plain fabric marker

making is relatively simple but on striped fabric, matching of fabric requires

utmost care. The Computer Aided marker making system is considered to be an

easier way for preparing markers.

Related Topics