Chapter: Total Quality Management : TQM Principles

Total Quality Management(TQM) Principles

TQM PRINCIPLES

LEADERSHIP

DEFINED

Leadership is interpersonal

influence exercised in a situation and directed through communication process,

towards the attainment of a specialized goal or goals. Thus leadership is a

process of influencing the activities of an individual or a group for goal

achievement in a given situation.

LEADERSHIP

CONCEPT

Leadership requires in order to

become successful as a leader , he needs an intimate and insightful

understanding of human nature – the basic needs, wants and abilities people, a

leader needs to know and understand the following;

1. People need both security and

independence at the same time.

2.People are sensitive and do respond to external rewards or

punishments. They are also strongly self-motivated.

3.Peoples sometime value a kind word of praise more than any

monetary reward.

4. They trust their gut reaction more

than statistical data.

5. A leader should simplify the task

ROLE

OF SENIOR MANGEMENT

Ø Senior management must practice

the philosophy of Management By Wandering Around (MBWA). They should get out of

the office and visit customers, departments, and plants within the organization

and suppliers

Ø Encourage subordinates to write

only important messages that need to be part of the permanent record.

Ø Senior management role is no

longer to make the final decision, but to make sure the teams decision is

aligned with the quality statement of the organization

Ø Problem solving and decision

making to the lowest appropriate level by delegating authority and

responsibility.

Ø Senior managers must stay informed

on the topic of quality improvement by reading books and articles attending

seminars and talking to other TQM leaders.

Ø The needed resources must be

provided to train employees in the TQM tools and techniques, the technical

requirements of the job and safety.

Ø Must be visibly and actively

engaged in the quality effort by serving on teams, coaching teams and teaching

seminars.

Ø They should lead by demonstrating,

communicating, and re-in forcing the quality statements.

Ø They should spend about one third

of their time on quality

Ø Senior managers are listening to

internal and external customers and supplies through visits, focus groups and

surveys.

Ø To create awareness of the

importance of TQM and provide TQM results in an ongoing manner.

Ø Senior managers should be able to

drive fear out of the organization, break down barriers, remove system

roadblocks, anticipating and minimize resistance to change and in general

change the culture.

QUALITY CIRCLE

Meaning

Quality council is composed of the

chief executive officer, the senior managers of the functional areas, such as

design, marketing, finance, production and quality and a coordinator or

consultant. Individual selected for the coordinated position should be bright

young person with execution potential.

Objectives

of quality council:

To raise the quality consciousness

in the organization through seminars, study tours and using forms of promotion.

To ensure effective functioning of

the organization on the quality statement and plan.

To encourage basic and applied

research and development in the field of quality and dissemination of its

results to the organization.

To raise the level of training of

personnel engaged in quality activities including the assessors and trainees.

To facilitate upgradation of

testing and calibration facilities and laboratories as well as to encourage the

overall quality of the organization.

DUTIES

OF QUALITY COUNCIL

q Develop with input from all

personnel; the core values Vision statement, Mission statement, and Quality

policy statement.

q Develop the strategic long term

with goals and the annual quality improvement program with objectives

q Determine and continually monitor

the cost of poor quality.

q Create the total education and

training plan.

q Determine the programme measures

for the organization.

q Continually determine those

projects that improve the process.

( internal and external customers)

q Establish or revise the

recognition and reward system to account for the new way of doing business.

QUALITY STATEMENT

In addition to the core values and

concepts, the quality statement includes the Vision statement, Mission

statement and Quality policy statement. Once developed they are occasionally

revised and updated. They are part of the strategic planning process, which

included goals and objectives.

VISION

STATEMENT

The vision statement is a clear

declaration of what an organization aspires to be in the future (in long term).

Its purpose is to provide a platform for the managers for thinking

strategically. A vision statement is usually an ideal condition, that might

never be reached but that will inspire the people to achieve.

Example: “THE HAPPIEST PLACE ON EARTH” - Disney Theme park.

MISSION

STATEMENT

The mission statement answers the

following questions. Who we are, who are the customers, what we do and how we

do it. This statement is usually one paragraph or less. It is easy to understand

and describe the functions of the organization. It provides a clear statement

of purpose for employees, customers and supplies.

EXAMPLE:

BEN & JERRY‟S ICE CREAM – MISSION STATEMENT

PRODUCT

MISSION: TO make, distribute and sell the finest quality natural ice cream and

related products in a wide variety of innovative flavors made from Vermont

dairy products.

QUALITY

POLICY STATEMENT

QPS serve as a guide for everyone

in the organization. This statement clarifies the employees about how the

products and services must be provided to the customers. The CEO of the company

writes quality policy statement after a careful study and analysis of the

feedback from the workforce. Finally the quality council must approve the

statement.

EXAMPLE:

Meet

the requirements of the customers (both internal and external)

Go

ahead competition

Complete

utilization of the entire workforce.

STRATEGIC PLANNING

Organizations are finding that

strategic quality plans and business plans are inseparable. The strategic

planning is three to ten years and short term planning is one year or less. It

consists of goals and planning.

SEVEN

STEPS TO STRATEGIC PLANNING.

1. Identification of customer needs.

2. Determination of customer

positioning

3. Predict the future.

4. Gap analysis.

5. Closing the gap.

6. Aligning the plan to the mission

and vision.

7. Implementation of the plan.

1.

Identification of customer needs.

This steps provides a focus on customer satisfaction.

There needs and wants have to be

identified and satisfied.

The profile of the customers are

identified. Questions like who are our customers? Will they change in future?

What will they want in future?.

2.

Determination of customer positioning

The planners determine where the

organization wants to be in relation to the customers.

Expand the customer base products

or services.

Products with poor quality

performance should be removed or eliminated and replaced by better ones.

The organization needs to

concentrate its efforts on areas of excellence

3.

Predict the future

Predict the future conditions that

will affect their product or service Using effective tools for analyzing and

predicting future

Some products or services have

become absolute because it failed to foresee the changing technologies.

The mangers in the organization

anticipate a change in the first place, and then they can make necessary

arrangements by making investments on resources and be prepared to take on the

future.

The rate of change is continuously

increasing.

4.

Gap Analysis

The planners to identify the gaps

between the current state and future state.

The present position of the organization in the market in relation to

competition, profits, customer satisfaction employee satisfaction, etc. to the

intended position.

If any there is gap identified future strategies must be formulated

taking this gap in to consideration.

5.

Closing the Gap

After gap analysis plans must be formulated to reduce or close the

strategic gap.

To close the gap by establishing

goals and responsibilities.

All stakeholders should be

included in the development of the plan.

6. Alignment

It must be aligned with the mission,

vision, and core values and concepts of the organization.

7. Implementation

a. Resources

must be allocated to collecting data, designing changes and overcoming

resistance to change.

b. To

monitoring activities to ensure that progress is being made.

Monitoring by the steering

committee and periodical assessments are required for an effective and speedy

implementation

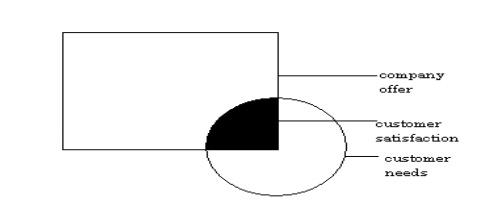

CUSTOMER

SATISFACTION

CUSTOMER

SATISFACTION MODEL:

CUSTOMER:

A customer can be defined as one

who purchases a product or service. There are two distinct type of customer.

Customer satisfaction is achieved

when their expectations are matched by what is offered to them by the

organization. It is important for the organization to listen to the voice of

the customers to ensure that is marketing, production, R&D , distribution

and service truly meet the expectations of the customers.

There are two distinct types of

customers; they are external and internal customers.

A)External

Customers:

External customers can be defined

as the one who purchases the product of the organization for end usage or for

reselling or to use the product in his production process as raw material.

B)

Internal customers:

Internal customers are the

employees of the organization. As far as the top management in concerned they

have an obligation to keep internal customers satisfied.

CUSTOMER

PERCEPTION OF OUALITY:

An American society for quality

(ASO) survey on end user perception of

important factors that influenced purchases showed the following ranking.

1. Performance

2. Features

3. Service

4. Warranty

5. Price

6. Reputation

1.

PERFORMANCE

Performance of

the product is the ―fitness‖ the product or

service by the customer at the time of sale.

It indicates that

the product can be used as such without any further modification.

Availability,

which is the probability that a product will operate when needed.

Reliability is

the consistent performance of the product every time is used Maintainability

which is the ease of keeping the product operational is also important.

2. FEATURE

Features are the secondary

characteristics or added facilities available with the core product.

FOR

EXAMPLE:

Primary function of an automobile

is transportation where as stereo system is a feature.

3. SERVICE:

Service

is emerging as a method for organizations to give the customer added value.

The product may work fine but if the service

which is attached to the product is not managed properly then it will lead to

customer dissatisfaction.

FOR

EXAMPLE:

Purchase of Air conditioner, the

seller has to come to your home to install and run the A/C machine. After that

he must come and service the A/C with regular internal and incase of any

problem immediately come and repair the problem.

4. WARRANTY:

The

warranty encourages customer to buy a product a service by reducing the risk of

the purchase division.

5. PRICE:

Customer is willing to pay a

higher price to obtain value. he evaluating product and services against those

of its competitors who provides the greatest value.

6. REPUTATION:

Find organizations by our overall

experience with them.

Customer satisfaction is based on

the entire experience with the organization not just the product.

FEEDBACK:

Customer feedback must be

continually solicited and monitored. Customer continually changes. They change

their minds, their expectations and their supplies. Customer feedback is not a

one-time effort it is a ongoing and active probing of the customer‘s mind.

IT ENABLES THE ORGANIZATION:

Discover customer

dissatisfaction.

Discover relative

priorities of quality.

Compare

performance with the competition.

Identify

customer‘s needs.

Determine

opportunities for improvement.

TOOLS USED:

1.

COMMENT CARD –attach with warranty

card.

Comment cards are simple cards

usually in the form of prepaid postage card which can be attached with the

product manual or the warranty card. or just included with the product the time

of purchase.

2.

Survey.

It is more effective and also

popular tool for obtaining opinions and perceptions about an organization and

its products and services.

Customers are asked to furnish the

answers related to the quality of the product and service.

3.

Focus group.

The focus group is like an in

depth interview, except that it involves a group rather than an individual. It

is a group interview that tries to stimulate people to talk freely about the

products.in a typical focus group, a few customers are invited to attend a

group discussion at a central interviewing location.

4.

Toll-free telephone numbers.

Toll free phone numbers (1600 –

inIndia, /800/888 in US) are an effective technique for receiving customer feedback.

Organizations can respond faster and more cheaply to a complaint on receiving a

complaint call.

5.

Customer visits.

Company personnel visiting

customers at their place will provide valuable information and feedback on the

product.

6.

The Internet

Web home pages and e-mails have

become very popular these days that they are fast replacing the conventional

methods of feedback mechanism.Customers also find it very easy and cheaper to

provide feedback to the supplier.

Using

customer complaints:

Every single complaint should be

accepted, analyzed and acted upon for its represents.

Information on customer

dissatisfaction is received into

the organization at the highest

level, there by providing a fast response.

Complaints can be seen as

opportunity to obtain information and provide a positive service to the

customers.

Activities

of the customer complaints:

Investigate

customer‘s experiences by actively soliciting feedback both positive and

negative and then acting it promptly.

Develop

procedures for complaint resolution.

Analyze

complaints but under stand that complaints do not always fit in to neat

categories.

Survey

response is received a senior manager should contact the customer and strive to

resolve them.

Establish

customer satisfaction measures and constantly monitor them. Provide a monthly

complaint report to the quality council for their evaluation and improvements.

SERVICE

QUALITY

CUSTOMER SERVICE is the set of

activities an organization used to win and retain customer‘s satisfaction. It

can be provided before during or after the sale of the product or exits on it‘s

own.

ELEMENTS

OF CUSTOMER SERVICE:

ORGANIZATION:

Identify

each market segment.

Write

down the requirements.

Communicate

the requirements.

CUSTOMER CARE:

Meet the

customer expectations. Get the customer point of view. Deliver what is

promised.

Make the

customer feel valued. Respond to all the complaints. Over respond to the

customer.

Provide a

clean and comfortable customer reception area.

COMMUNICATION:

Optimize

the trade-off between time and personal attention.

Minimize

the number of contact points.

Provide

pleasant knowledgeable and enthusiastic employees.

Write

documents in customer friendly language.

FRONT-LINE PEOPLE:

Serve

them as internal customer.

Hire people

who like people.

Give them

the authority to solve the problem.

Challenge

them to develop better methods.

Be sure

they are adequately trained.

Recognize

and award performance.

LEADERSHIP:

Lead by

example.

Listen to

the front-line people.

Strive for

continuous process involvement.

CUSTOMER

RETENTION

Wheather retail or industrial

customer, are constantly watching out for better cheaper products and when a

competitor is able to offer the product better, that the customers usually

switch.

Any organization should develop a

very personal relationship with individual customers, so that they do not

switch over to the competitors.

CUSTOMER RETENTION represents the

activities the produce the necessary customer satisfaction that creates

customers loyalty, which actually improves the bottom line.

EMPLOYEE

INVOLVEMENT

TQM requires everybody‘s

involvement in the process and everyone should feel that the company belongs to

them. Employee involvement results in improved quality and productivity.

MOTIVATION:

MEANING/DEFINITION:

1. Motivation is a process that

starts with a physiological or psychological deficiency or need that activates

behavior or a derive that is aimed at a goal or an incentive.

2. Motivation is the result of

processes internal and external to the individual that arouse enthusiasm and

persistence to pursue a certain course of actor.

THEORIES

OF MOTIVATION:

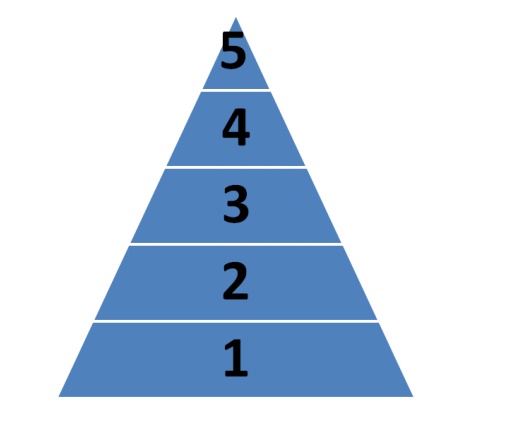

MASLOW

THEORY

According to this theory every

individual is depicted as a wanting organism with a desire to rise from one

level to another level in the society. Maslow suggests five levels for every

individual with differing needs at every level.

1. Basic or

physiological needs

The first need of a person is

physiological in nature. physiological needs are the necessities for survival.

Once this need is satisfied, they no longer act as motivators for the employee.

These factors when available are taken for granted and employees look for the

next level as motivators.

2.

Security or safety needs.

Employees now strive to achieve

the next level which is safety needs. These needs include safe place of work

and job security, which are very important for employees.

3. Social needs.

Since a man is social being, he

has a need to belong and to be accepted by the various groups. When social

needs are dominant, a person will strive for meaningful relationship with

others. He gets a fear of being rejected.

Conversely when an individual has

an opportunity to be a part of a group by feeling important and needed will

motivate that person.

4. Esteem needs.

Self esteem needs are concerned

with self respect, recognition, self worth and feeling of being unique.

5.

Self- actualization.

Individuals in an organization

must be given the opportunity to go as far as their abilities will take them.

Many organizations have a policy of promoting employees from within. This

motivates employees to contribute their maximum to the organization.

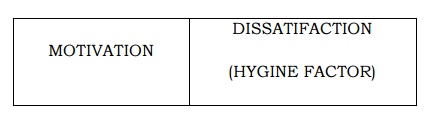

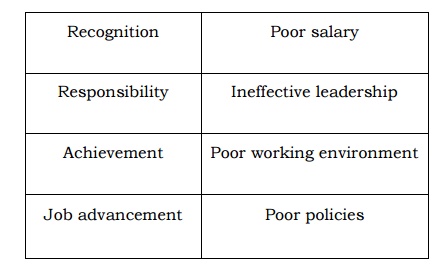

HERZBERG‟S

TWO-FACTOR THEORY:

He identified that people were

motivated by recognition, responsibility, achievement and job advancement. He

labels these factors as motivation.

He also identified that bad

feelings were associated with low salary, minimal fringe benefits. Power

working environment and ineffective supervision.

These factors were labeled as

dissatisfaction or hygiene factor

It should note that the presence

of extrinsic (hygiene factors) results in dissatisfaction, but the absence of

motivating factor does not make employee dissatisfied.

EMPLOYEE

EMPOWERMENT

MEANING:

Employee empowerment is making a

person completely responsible for a particular task; the individual who is

empowered becomes the process owner.

In the empowerment the individual

in given complete authority required to execute the process and ownership is

created.

Condition:

·

Every

one should understand the need for change in culture and attitude.

·

The

system must change to the new paradigm.

·

People

should be provided with necessary resources.

Empowerment is an environment in

which people have the ability the confidence and the commitment to take the

responsibility and ownership to improve the process and initiate the necessary

steps to satisfy customer requirements within well-defined boundaries in order

to achieve organizational values and goals

TEAMS

T-together E-everyone A-achieve

M-more

A team is defined as a group of

people working together to achieve common objectives or goals.

Teamwork is the cumulative actions

of the team during which each member of the team subordinates his individual

interests and opinions to fulfill the objectives or goals of the group.

TYPES OF TEAM

1. Process improvement team.

Here, five to six members from

various disciplines of the organization are brought together to solve a

problem. Usually the scope of the team is limited to the work unit.

The life cycle of the team is

usually temporary. The team is disbanded after the problem (process improved)

is solved.

2.

Cross-functional team.

Here the team is constituted by

the number of different functional areas such as production, engineering,

marketing, finance, e etc. it may also include customers and suppliers.

3. Natural team.

This type of team is not voluntary

in nature as it was with other teams. Here all members of the work unit are in

the team and the manger is also part of the team.

4. Self-management work groups.

They are an extension of natural

work team without the supervisor. These teams are the essence of the empowered

organization. These teams not only do the work but also manage it.

STAGES

OF TEAM DEVELOPMENT:

1. Forming.

Forming is the fist and beginning

stage of the life cycle of a team.

A facilitator is appointed by the

quality council and he meets with the senior management to charter the path the

solution of the problem should take.

Once team is assembled, a meeting

is called and the facilitator briefs the problem to the team, and then

determine the type of training the team members may need and identify an

appropriate team leader.

2. Storming.

In this stage all members of the

team are fully aware of the quality problem they are faced with.

They will be interested in proving

themselves by exhibiting their individual skills.

3. Norming.

In this stage members have

understood each other well. Everyone knows each others strengths and weakness

and capabilities and limitations.

The roles of the members are

clearly defined, mission and objectives are clear and the course to be taken to

solve the problem is also clear.

4. Performing.

In this stage, the team members

have understood the project better and begin performing by diagnosing and

solving problems and choosing and implementing changes.

BARRIES

OF TEAM PERFORMING:

1.

Poor training for the group members.

2. Improper reward schemes.

3. Lack of planning.

4. Lack of management commitment in

monitoring the team program.

5. Poor communication.

6. Too many members in team.

Role

of team leader:

1. Ensure the smooth and effective

operation of the team.

2. Handling and assigning the

responsibilities.

3. Good record keeping.

4. Preparing and presenting the

report.

5.

Prevents

other members from dominating.

6. Use positive interpersonal

dominating.

7. Serve as a contact point between

the team and qty council.

8. Monitors the status and

accomplishments of member assuming firmly completion of assignments.

9. Prepares the meeting agenda i.e.

time, date, location.

Role

of team member:

1. Contributes best.

2. Sharing knowledge.

3.

Listen

carefully and ask question.

4. Negotiate important points.

5. Supports the decisions of the

team.

6. Trust support concern for other

team members.

7. Understands and is committed to

team objectives.

8. Respects and is tolerant of

individual differences.

9. Acknowledges and worker through

conflict openly.

10.Carries out assignments between

meetings such as connecting data observing charting data and returning report.

11.Gives honest sincere

appreciation.

Recognition

and reward:

Recognition and reward are basic

motivational tools used to motivate employees to encourage them to maintain and

improve their present level.

Publicly

acknowledging the contributions of an individual is called recognition.

This acknowledgement may be in the

form of a certificate or a verbal praise.

On the other hand the rewards are

tangible such as cash reward, gold coins etc

Reward can be delayed but the

recognition of the contributions must be done immediately.

Purposes:

1. Reward system reminds the

continual improvement required for the TQM journey.

2. Serves as a platform for

encouraging the super performances.

3. Serve as a goal for the employee.

4. Serve as a morale booster.

Performance

appraisal

Performance appraisal is the

judgement of employee‘s performance in the organization.

Performance appraisal is defined to

show the employees how they are doing. This serves as a basis for promotion,

salary increases etc those who are rated poorly should be allowed to undergo

special counseling and skill up-grading programmer.

It should help people to assess

themselves and improve.

Appraisal

format:

1. Ranking- compares employees by ranking

from highest to lowest.

2. Narrative-

gives a written description of

employee‘s strength and weakness.

3. Graphic-indicate the major duties

performed by the employees and rate each

duty with a sale, which is usually from 1(poor) to 5(excellent).

4. Forced

choice-places

each employee‘s in a category with a predetermined percentage for example excellent 10%, very poor 25%, grave 30%,

fair 25%, poor10%.

BENEFITS

1. PROMOTION

2. SALARY INCREASE

3. BONUS

4. INCENTIVES

5. INDENTIFYING TRAINING NEEDS

6. IMPRORING SKILLS OF THE EMPLOYEE‘S

7. TO IMPROVE EMPLOYEE PERFORMANCE

8. TO RATING THE CUSTOMERS.

CONTINUOUS PROCESS IMPROVEMENT

CPI is the care of TQM. CI in the

business process as war as production process is desired for the growth of the

organization.

CPI is possible by

1. Making all process effective and

adaptative.

2. Accepting the change in the

customer requirements and tuning ourselves to meet demand.

3. Improving the productivity by

eliminating waste.

4. Permanently eliminating the ‘non-value

adding activities‘.

5. Our self with the best player in

the field.

6. Using advanced tool like

DOE(design of experiments), SPC, quality function development etc .

JURAN‟S

TRILOGY

Juran‘s trilogy consists of three

managing process quality planning, quality control and quality improvement.

Quality

planning:

The quality planning starts with identifying external customers of a business.

Identify who are the customers.

·

Determine

the needs of those customers

·

Translate

those needs into the business possibility

·

Develop

a product that can respond to those needs

·

Optimize the

product features so as to meet

the organizations needs and

customer‘s needs.

Quality

Improvement

Develop a process which is able to produce the Product.

Optimize the process.

Quality

control:

Prove that the process can be

producing the producet under operating conditions with minimal inspection.

Transfer the process to

operations.

The

quality control involves checking the products produced with specification.

QUALITY

IMPROVEMENT STRAREGIES

1.

REPAIR:

There are two levels of repair.

a)

In

the first level the team or an individual working in the process identifies the

problem and eliminates the root cause of the problem. This brings in permanent

solution for the problem.

b) In the next level the faulty

product reaches the customer. The customer then indicates that he has received

a bad product and the product is either replaced or repaired. This is temporary

solution to the problem.

c)

It

is important to note that the repair strategy will not make the process better

than the original design.

2.

CONTINUOUS IMPROVEMENT/

REFINEMENT:

Refinement

is doing things a little bit, faster, better, easier, or with less waste.

It is

the process products and services are required to keep the quality improvement

process alive. But management may fail to notice the small improvement and

influence fail to reward the improvement efforts. This will result in

dissatisfaction and loss of involvement.

3.

INNOVATION:

The processes and products by

innovative methods.

For example: automation of

process.

4.

PARADIGM SHIFT (RE-INVENTION):

When a

company understand that the existing processes cannot ensure the customer

satisfaction it is better to reinvent the process.

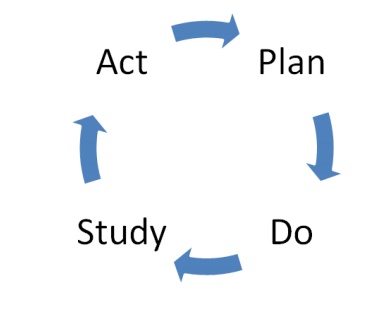

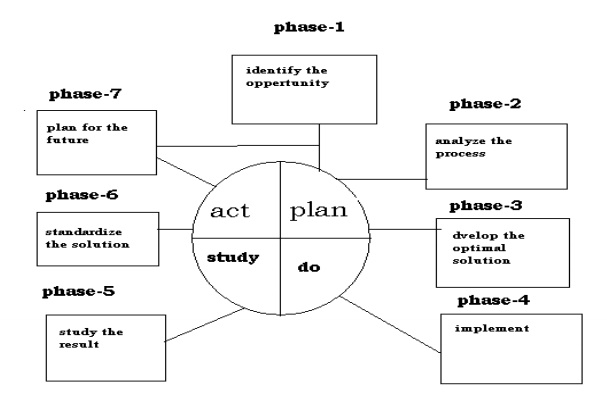

PDSA CYCLE

STEWART developed the

plan-do-check-act (PDCA) cycle and late Deming modified it to plan-do-study-act

(PDSA) cycle.

Plan:

By management. Do: By the operator. Study:

quality manager Act: management

Plan

It is important to establish the stage of the

change to be introduced.

Plan on how you are going to collect the

information about the differences that occur after the implementation of the

plan.

What is to be done and how to achieve.

Do:

Put the plan into practice.

There may be changes that should

only be measured over long periods.

Record any unexpected event,

problems and other observations. Star analyzing the data.

Study

Review and reflect on the data

collected in the previous step

Find out whether there has been

any improvement in the process. Did your expectations match the reality of what

happened?

Find out what could have been done

differently.

Act

Carry out an amended version of

what happened during the ―Do" stage and measure any differences

PROBLEM

SOVING METHOD FOR PROCESS IMPROVEMENT.

5s-concept

1. Seiko (Proper arrangements)

This is the proper identification

of materials, equipments and tools, data and information which are necessary or

not necessary,.

Provide the necessary space for

the required or necessary items which you require to perform the necessary

task.

2. Seiton (orderliness)

Every equipment or data or anything

should be placed in its appropriate and unique place.

So that a simple eraser or pencil

can be found at the same place every time by everybody in the organization.

This reduces confusion and avoids

wastages of time.

The place in which it is stored

should be easily accessible and appropriate.

3. Seiso (Cleanliness)

The shop floor should be free of

wastage, oil spills, cotton wastes etc., The tools also should be clean, the

machines should be clean and the entire organization should be free from dirt

and any unexpected objects lying around.

Keep the work place clean and make

data and information easily available and constantly updated in order to

support decision making.

4. Seiketsu (personal cleanliness).

A person should be clean and his

cloths should be clean. Only a clean person can be conscious about keeping his

workplace clean and neat. Moreover unclean person present a work situation were

co-workers become uncomfortable to work in.

Personal cleanliness automatically

creates a favourable condition at work place for physical and mental health,

free from dirt, pollutants etc.

5. Shitsuke (Discipline).

This may not only be the jobs

related to the organization but also personal work.

Job discipline is the habit and

skill development to perform the job according to standards, to observe company

rules and policies at all times.

This habit of discipline is

developed as a result of excursing mental, moral and physical strength.

KAIZEN

The philosophy that defines

management role in continuously encouraging and implementing small improvements

involving everyone.

It is the process of continuous

improvement in small increments that make the process more efficient,

effective, under control and adaptable.

Improvements are usually that make

the accomplished at little or no expenses without sophisticated techniques or

expensive equipment. It focuses on simplification.

Kaizen is possible only when the

management is able to hear the workers. It requires an effective communication

in both the directions.

KAIZEN

REQUIRES THE USE OF THE FOLLOWING:

1. The data about value adding and

non-value adding activities.

2. The knowledge about various types

of waster (Muda). Over production, delay, transportation, processing,

inventory, wasted motion and defective parts.

3. Documentation of the operating

procedure.

4. Principles of time study.

5. Following the 5s concept.

6. Fewer inventories – use JIT.

7. Mistake proofing- to prevent or

detect errors.

8. Effective use of teams to solve

problems and to improve the performance.

SUPPLIER PARTNERSHIP

The

relationship between customer (company) and the supplier. Customer and supplier

have the same goal to satisfy the end user. Both the customer and the supplier

have limited resources they must have work together as partners to maximize

their return on investment.

Principles of customer-supplier

relations:

1. Both the customer and supplier are

responsible for the quality control.

2. Supplier and customer should be

independent of each other.

3. The customer must communicate to

the supplier about his requirements.

4. There should be agreement with

respect to quality, price, mode of delivery and payment mode.

5. The supplier should supply quality

materials that will result in customer satisfaction.

6. Provisions for the easy settlement

of the disputes.

7. Mutual exchange of information.

PARTNERING

Meaning:

Partnering is a long-term

commitment between two or more organization for the purpose of achieving

specific business goals and objectives by maximizing the effective of each

participants resources.

Benefits:

1. Improve quality.

2. Increased efficiency.

3. Lower cost.

4. Opportunity for innovation.

5. Continuous improvements of product

and services.

KEY

ELEMENTS OF PARTNERING:

1.

LONG-TERM COMMITMENT:

Long-term commitment provides the

needed environment for both partners to work toward continuous improvement.

Problems require time to solve or

process need constant improvement.

Each partner contributes its

unique strengthen to the processes.

Investment in new equipment or

systems may be required.

These

must be a to far organization involvement from the CEO to the workers.

2. TRUST:

Mutual trust forms the basis for a

strong working relationship.

Open and frequent communication

avoids misdirection and disputes while strengthening the relationship.

The parties should have access to

each other business plans and technical information.

They may share or integrate

resources such as training activities, administration systems and equipment.

Both parties become mutually

motivated when win-win solution not rather than win-lose solution.

3.

SHARED VISION:

Shared goal and objectives ensure a common

direction and must be aligned with each parties.

Employees of both parties should think and act

for their common good.

Understand each other‘s business

so that equitable decision are made

Sharing of business plan.

SOURCING

SOURCING is the process of

identifying the suppliers for the items required by an organization for produce

or manufacturing the product. There are three types of sourcing

1.

Sole sourcing:

The organization is forced to use

only one supplier. Only one organization producing the item.

2.

Multiple sourcing:

Two or more suppliers are

available for the required item.

It eliminates dependency.

Usually these suppliers are chose

in term of price, quality and delivery.

It will result in better quality

low cost and better service.

If there is a strike going on in

one of the supplier‘s company the manufacturer need not wait for him.

3.

Single sourcing:

Though there are number of suppliers available

for a particular commodity selecting a single vendor for the organization to

supply the item is called single sourcing.

It results in long-term product.

Supplier

Selection

The company before going for selecting a

supplier should finalize on ―Make or Buy‖ decision. The following questions

must be answered before

proceeding with the suppliers.

1. How critical is the item to the

final product/ service

2. Is it possible to produce the item

internally? Do we have technology to produce it? If not, can we develop it?

3. Are there any specialized

suppliers for the item? Or can we develop such a supplier?

Finally the decision is made to

outsource, the following points must be considered for evaluating the

suppliers.

a.

The supplier‘s

ability to understand the management philosophy of the organization.

b. The technical expertise available

now and the ability to cope up with the future technical requirements.

c.

The supplier‘s

ability to consistently supply the raw materials that meet the specifications of the purchaser.

d. The supplier‘s ability to meet the demand and

ability to increase the volume of

production when demanded.

e.

The

credibility of the supplier in maintaining the corporate secrets.

f.

System

of delivery and communication systems available with the supplier.

g. The track record of the supplier

with the company.

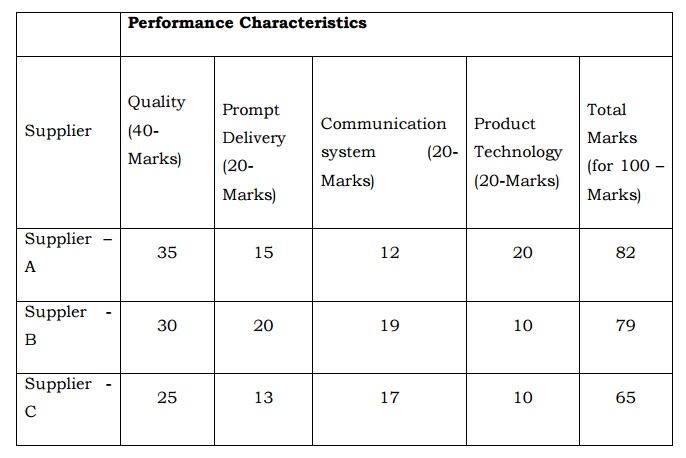

Supplier

Rating.

To assess the performance of the

suppliers with respect to quality, speed if delivery, and service, the supplier

rating is done. Supplier rating is the process of categorizing the suppliers on

the basis of quality, prompt delivery, and services.

1.

Supplier

rating enables the company to obtain an overall rating of the supplier

performance.

2.

It

ensures complete communication with customers on all the key areas.

3.

It

enhances the customer- supplier relationship by providing an objective feedback

of the supplier‘s performance.

4.

It

provides the supplier‘s with a factual record of mistakes, so that the

suppliers can eliminate them in future.

For example

Supplier Rating System. - Scorecard.

The above the clearly show - the

supplier –A having more score comparing with the B and C. so it is conclude

that the supplier –A is good performance.

RELATIONSHIP DEVELOPMENT

Sustaining

the relationship with the suppliers is important after initiating the customer

supplier partnering process. To keep the relationship alive and growing the

following activities are carried out.

1. Inspection

The purpose of this inspection

process is to gain confidence in each other‘s performance and finally

automating the inspection activity. There are four phase in the inspection

process.

a.

100%

inspection

b. Sampling inspection

c.

Audit

d. Identity Checks.

2. Training

It is always better to educate the

suppliers on what we expect from them and what quality means to us in the

business process. This is possible by allowing the suppliers to undergo

training programmes conducted by the senior officials at customer‘s sites.

3.

Team Effort

In all the possible areas the

teams must involve officials from the suppliers side also. This will enhance

the understanding of the suppliers and their role in the business process will

be clear to them.

The team meeting must be arranged

at both the customer and the supplier premises.

4.

Recognition

The

customer should

recognize the supplier‘s performance by awarding them with a place in the preferred suppliers list. A certificate

of contribution to the business must be given to them. This recognition will

surely develop the relationship between the customer and the supplier

Related Topics