Chapter: Mechanical : Unconventional machining process : Thermal Energy Based Processes

Thermal Energy Based Processes

THERMAL ENERGY BASED PROCESSES

· Laser–Beam Machining (LBM)

Electron

Beam Machinin g (EBM)

· Plasma Arc Machining (PAM)

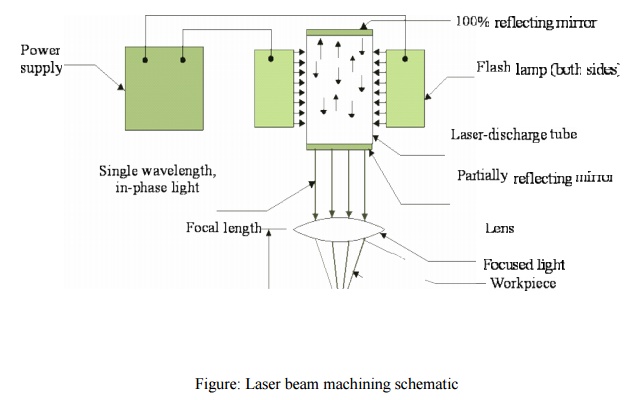

1. Laser–Beam Machining

Laser-beam

machining i s a thermal material-removal process that utilizes a high-energy,

Coherent light beam to melt and vaporize particles on the surface of metallic

and non-metallic work pieces. Lasers can be ussed to cut, drill, weld and mark.

LBM is particularly suitable for making accurately placed hol es. A schematic

of laser beam machining is s hown in Figure

Different types of lasers are a

vailable for manufacturing operations which are as follows:

• CO2 (pulsed or continuous wave): It

is a gas laser that emits light in the infrared region. It can provide up to 25

kW in continuous-wave mode.

•

Nd:YAG:

Neodymium -doped Yttrium-Aluminum-Garnet (Y3Al5O 12) laser is a solid- state

laser which can deliver light through a fibre-optic cable. It c an provide up

to 50 kW power in pulsed m ode and 1 kW in continuous-wave mode.

Figure: Laser beam machining

schematic

Applications

LBM can make very accurate holes as

small as 0.005 mm in refractory metals ceramics, and composite material without

warping the work pieces. This process is used widely for drilling

Laser beam cutting (drilling)

•

In

drilling, energy transferred (e.g., via Nd YAG laser) into the workpiece melts

the material at the point of contact, which subsequently changes into a plasma

and leaves the region.

•

A

gas jet (typically, oxygen) can further facilitate this phase transformation

and departure of material removed.

•

Laser

drilling should be targeted for hard materials and hole geometries that are

difficult to achieve with other methods.

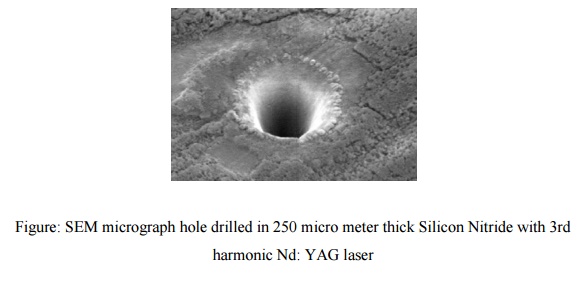

A typical SEM micrograph hole

drilled by laser beam machining process employed in making a hole is shown in

Figure

Figure:

SEM micrograph hole drilled in 250 micro meter thick Silicon Nitride with 3rd

harmonic Nd: YAG laser

2

Laser beam cutting (milling)

•

A

laser spot reflected onto the surface of a workpiece travels along a prescribed

trajectory and cuts into the material.

•

Continuous-wave

mode (CO2) gas lasers are very suitable for laser cutting providing

High-average power, yielding high material-removal rates, and smooth cutting

surfaces

Advantage of laser cutting

•

No

limit to cutting path as the laser point can move any path.

•

The

process is stress less allowing very fragile materials to be laser cut without

any support.

•

Very

hard and abrasive material can be cut.

•

Sticky

materials are also can be cut by this process.

•

It

is a cost effective and flexible process.

•

High

accuracy parts can be machined.

•

No

cutting lubricants required

•

No

tool wear

•

Narrow

heat effected zone

Limitations of laser cutting

•

Uneconomic

on high volumes compared to stamping

•

Limitations

on thickness due to taper

•

High

capital cost

•

High

maintenance cost

•

Assist

or cover gas required

3

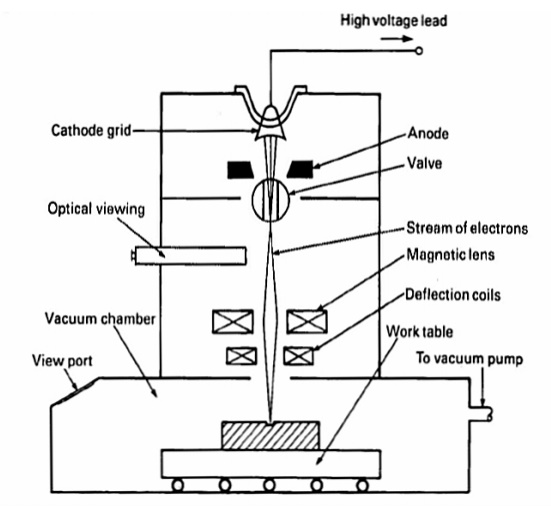

ELECTRON BEAM MACHINING (EBM)

As

has already been mentioned in EBM the gun is operated in pulse mode. This is

achieved by appropriately biasing the biased grid located just after the

cathode. Switching pulses are given to the bias grid so as to achieve pulse

duration of as low as 50 μs to as long as 15 ms. Beam current is directly

related to the number of electrons emitted by the cathode or available in the

beam. Beam current once again can be as low as 200 μamp to 1 amp. Increasing

the beam current directly increases the energy per pulse. Similarly increase in

pulse duration also enhances energy per pulse. High-energy pulses (in excess of

100 J/pulse) can machine larger holes on thicker plates. The energy density and

power density is governed by energy per pulse duration and spot size. Spot

size, on the other hand is controlled by the degree of focusing achieved by the

electromagnetic lenses. A higher energy density, i.e., for a lower spot size,

the material removal would be faster though the size of the hole would be

smaller. The plane of focusing would be on the surface of the work piece or

just below the surface of the work piece.

1. Electrons generated in a vacuum

chamber

2. Similar to cathode ray tube

3. Electron gun

4. Cathode - tungsten filament at 2500

– 3000 degC

5. Emission current – between 25 and

100mA (a measure of electron beam density)

MRR:

In the region where the beam of

electrons meets the workpiece, their energy is converted Into heat

Workpiece surface is melted by a

combination of electron pressure and surface tension Melted liquid is rapidly

ejected and vaporized to effect material removal

Temperature of the workpiece

specimen outside the region being machined is reduced by pulsing the electron

beam (10 kHz or less)

Advantages

of Ebm:

1. Large

depth-to-width ratio of material penetrated

by the beam with applications of very fine hole drilling becoming feasible

2. There

are a minimum nu mber of pulses ne associated

with an optimum accelerating Voltage. In practice the number of pulses to

produce a given hole depth is usually

found to decrease with increase in accelerating voltage.

4.

PLASMA ARC MACHINING (PAM)

The

plasma welding process was introduced to the welding industry in 1964 as a

method of bringing better control to the a rc welding process in lower current

ranges. Todday, plasma retains the original advantages it brought to industry

by providing an advanced level of control and accuracy to produce high quality

welds in miniature or precision applications and to provide long electrode life

for high production requirements.

The plasma process is equally suited

to manual and automatic applications. It has been used in a variety of

operations ranging from high volume welding of strip met al, to precision

welding of surgical instruments, to automatic repair of jet engine blades, to

the manual welding of kitchen equipment for the food and dairy industry.

5. PLASMA ARC WELDING (PAW):

Plasma arc welding (PAW) is a

process of joining of metals, produced by heating with a constricted arc

between an electrode and the work piece (transfer arc) or the electrode and the

constricting nozzle (non transfer arc). Shielding is obtained from the hot

ionized gas issuing from the orifice, which may be supplemented by an auxiliary

source of shielding gas. Transferred arc process produces plasma jet of high

energy density and may be used for high speed welding and cutting of Ceramics,

steels, Aluminum alloys, Copper alloys, Titanium alloys, Nickel alloys.

Non-transferred arc process produces

plasma of relatively low energy density. It is used for welding of various

metals and for plasma spraying (coating).

Equipment:

(1) Power source. A constant current

drooping characteristic power source supplying the dc Welding current is

required. It should have an open circuit voltage of 80 volts and have a duty

cycle of 60 percent.

(2) Welding torch. The welding torch for

plasma arc welding is similar in appearance to a gas tungsten arc torch but it

is more complex.

(a) All plasma torches are water cooled,

even the lowest-current range torch. This is because the arc is contained

inside a chamber in the torch where it generates considerable heat.During the

non transferred period, the arc will be struck between the nozzle or tip with the

orifice and the tungsten electrode.

(b) The torch utilizes the 2 percent

thoriated tungsten electrode similar to that used for gas tungsten welding.

(3) Control console. A control

console is required for plasma arc welding. The plasma arc torches are designed

to connect to the control console rather than the power source. The console

includes a power source for the pilot arc, delay timing systems for

transferring from the pilot arc to the transferred arc, and water and gas

valves and separate flow meters for the plasma gas and the shielding gas. The

console is usually connected to the power source. The high-frequency generator

is used to initiate the pilot arc.

Principles

of Operation:

The plasma arc welding process is

normally compared to the gas tungsten arc process. But in the TIG-process, the

arc is burning free and unhandled, whereas in the plasma-arc system, the arc is

necked by an additional water-cooled plasma-nozzle. A plasma gas – almost

always 100 % argon –flows between the tungsten electrode and the plasma nozzle.

The welding process involves heating

a gas called plasma to an extremely high temperature and then ionizing it such

that it becomes electrically conductive. The plasma is used to transfer an

electric arc called pilot arc to a work piece which burns between the tungsten

electrode and the plasma nozzle. By forcing the plasma gas and arc through a

constricted orifice the metal, which is to be welded is melted by the extreme

heat of the arc. The weld pool is protected by the shielding gas, flowing

between the outer shielding gas nozzle and the plasma nozzle. As shielding gas

pure argon-rich gas-mixtures with hydrogen or helium are used.

The high temperature of the plasma

or constricted arc and the high velocity plasma jet provide an increased heat

transfer rate over gas tungsten arc welding when using the same current. This

results in faster welding speeds and deeper weld penetration. This method of

operation is used for welding extremely thin material and for welding multi

pass groove and welds and fillet welds.

Uses

& Applications:

Plasma arc welding machine is used

for several purposes and in various fields. The common application areas of the

machine are:

1. Single runs autogenous and multi-run

circumferential pipe welding.

2. In tube mill applications.

3. Welding cryogenic, aerospace and

high temperature corrosion resistant alloys.

4. Nuclear submarine pipe system

(non-nuclear sections, sub assemblies).

5. Welding steel rocket motor cases.

6. Welding of stainless steel tubes

(thickness 2.6 to 6.3 mm).

7. Welding of carbon steel, stainless

steel, nickel, copper, brass, monel, inconel, aluminium, titanium, etc.

8. Welding titanium plates up to 8 mm

thickness.

9. Welding nickel and high nickel

alloys.

10.

Melting,

high melting point metals.

11.

Plasma

torch can be applied to spraying, welding and cutting of difficult to cut

metals and alloys.

6

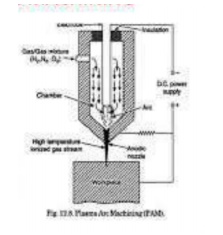

Plasma Arc Machining (PAM):

Plasma-arc machining (PAM) employs a

high-velocity jet of high-temperature gas to melt and displace material in its

path called PAM, this is a method of cutting metal with a plasma-arc, or

tungsten inert-gas-arc, torch. The torch produces a high velocity jet of

high-temperature ionized gas called plasma that cuts by melting and removing

material from the work piece. Temperatures in the plasma zone range from

20,000° to 50,000° F (11,000° to 28,000° C). It is used as an alternative to

oxyfuel-gas cutting, employing an electric arc at very high temperatures to

melt and vaporize the metal.

Equipment:

A plasma arc cutting torch has four

components:

1. The electrode carries the negative

charge from the power supply.

2. The swirl ring spins the plasma gas

to create a swirling flow pattern.

3. The nozzle constricts the gas flow

and increases the arc energy density.

4. The shield channels the flow of

shielding gas and protects the nozzle from metal spatter.

Principle

of operation:

PAM is a thermal cutting process

that uses a constricted jet of high-temperature plasma gas to melt and separate

metal. The plasma arc is formed between a negatively charged electrode inside

the torch and a positively charged work piece. Heat from the transferred arc

rapidly melts the metal, and the high-velocity gas jet expels the molten

material from the cut.

Applications:

The materials cut by PAM are

generally those that are difficult to cut by any other means, such as stainless

steels and aluminum alloys. It has an accuracy of about 0.008".

Related Topics