Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Testing Of Bricks

Testing Of Bricks

About fifty pieces of bricks are

taken at random from different parts of the stack to perform various tests. For

the purpose of sampling, a lot should contain maximum of 50,000 bricks. The

number of bricks selected for forming a sample are as per Table 2.3, (IS:

5454). The scale of sampling for physical characteristics is given in Table

2.4.

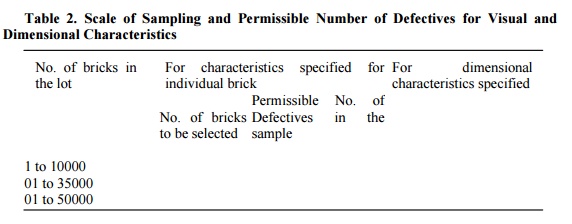

Table 2.

Scale of Sampling and Permissible Number of Defectives for Visual and

Dimensional Characteristics

Note: In

case the lot contains 2000 or less bricks, the sampling shall be subject to

agreement between the purchaser and supplier.

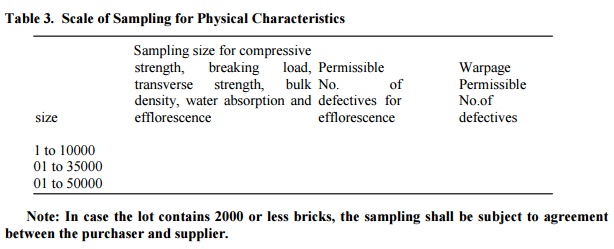

Table 3.

Scale of Sampling for Physical Characteristics

Note: In

case the lot contains 2000 or less bricks, the sampling shall be subject to

agreement between the purchaser and supplier.

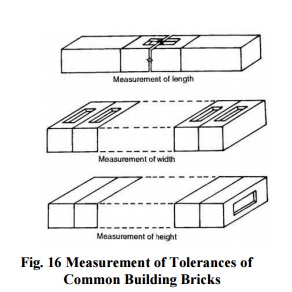

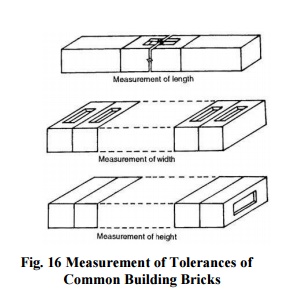

Dimension

Test (IS: 1077): 20 pieces out of selected pieces (Table)

are taken and are laid flat as shown in Fig. 16.

The

tolerances (Section ) on the sizes of bricks are fixed by giving maximum and

minimum dimensions, not on individual bricks but on batches of 20 bricks chosen

at random.

It

follows from this method of measurement that batches are likely to contain,

bricks outside the prescribed limit of tolerance. Such lots should be rejected

to avoid complaints about the variation of perpends.

Water Absorption Test (IS: 3495 (Part II)): The

existence of minute pores confers marked capillary properties on brick

ceramics. In particular all bricks absorb water by capillary action. The percentage

of water absorption is a very valuable indication of the degree of burning.

Vitrification, in the true sense, corresponds to such a dgree of compactness

that the absorption of the brick is not over 3 per cent after 48 hours of

immersion. It has been reported that for absorption less than 5 per cent danger

from frost is negligible.

Water absorption does not necessarily indicate the

behavior of a brick in weathering. Low absorption (< 7 %) usually indicates

a high resistance to damage by freezing, although some type of bricks of much

higher absorption may also be frost resistance. Since expansive force of water

freezing in the pores of a clay product depends upon the proportion of pore

space occupied, the ratio of the absorption after 24 hours submersion to the

absorption after boiling for 5 hours (C24/B5) appears to

be a better criterion of resistance to freezing than the percentage of

absorption.

The

durability of a brick may be tested by frost action, i.e., by alternate wetting

and drying. The absorption test has long been considered a measure of

durability, although the basis for this assumption is questionable. The suction

rate of the brick at the time it is laid exercises a mark influence on the

mortar bond. Too rapid withdrawal of water from the mortar by the brick

produces a weak bond. The rate at which a brick absorbs water, frequently

called its suction rate, maybe measured by immersing one face of the brick in

water. The one minute water uptake (initial rate of absorprion) is taken as the

suction rate. For long periods of immersion in theis test, the total wieght of

water absorbed per unit area,

w = AÖt

where, A is the water absorption coefficient

and t is the time elapsed in the test.

The standard methods of finding the absorption

value of the bricks are discussed below. If absorption by volume is desired it

can be obtained by multiplying the weight percentage by the apparent specific

gravity.24 Hours Immersion Cold Water Test: Dry bricks are put in an oven at a

temperature of 105 o to 115 o C till these attain constant mass. The weight (W1)

of the bricks is recorded after cooling them to room temperature. The bricks

are then immersed in water at a temperature of 27 o

± 2 o C for

24 hours. The specimens are then taken out of water and wiped with a damp

cloth. Three minutes, thereafter it is weighed again and recorded as W2.

The water

absorption in % = w2-w1/ w1 x 100

The average water absorption shall not be more

than 20 per cent by weight upto class 12.5 and 15 per cent by weight for higher

classes.

Five

Hours Boiling Water Test: The weight of the oven dried bricks (W1)

is recorded as above. Then the specimen is immersed in the water and boiled for

five hours, followed by cooling down to 27 o ± 2 o C by natural loss of heat

within 16-19 hours. The specimen is taken out of water

and wiped with a damp cloth and the weight is recorded as W3.

The water

absorption in % = W3W1 / W1 - 100

Compressive

Strength Test (IS: 3495 (Part I)): The crushing affords a basis for

comparing the quality of bricks but is of little value in determining

the strength of a masonry wall, since the latter depends primarily on the

strength of mortar. Six bricks are taken for the compressive strength test

althought it may be found that an individual brick varies by 20% or more from

the average, the permissible stresses allowed for load bearing walls take

account of this, being based on an average strength of six bricks. It is,

therefore, both unnecessary and uneconomical to insist that every bricks is

above a certain strength. As a criterion of structural strength for brick, the

transverse failure in a wall or pavement is likely to occur on account of

improper bedment. For testing bricks for compressive strength from a sample the

two bed faces of bricks are ground to provide smooth, even and parallel faces.

The bricks are then immersed in water at room temperature for 24 hours. These

are then taken out of water and surplus water on the surfaces is wiped off with

cotton or a moist cloth. The frog of the brick is flushed level with cement

mortar and the brick is stored under damp jute bags for 24 hours followed by

its immersion in water at room temperature for three days. The specimen is

placed in the compression testing machine with flat faces horizontal and mortar

filled face being upwards. Load is applied at a uniform rate of 14 N/m2

per minute till failure. The maximum load at failure divided by the average

area of bed face gives the compressive strength.

Compressive

strength (N/mm2)

= M aximum load at failure (N) / A verage area

of bed faces (mm)

average

of results shall be reported. The compressive strength of any individual brick

tested in the sample should not fall below the minimum average compressive

strength specified for the corresponding class

of brick by

more than percent.

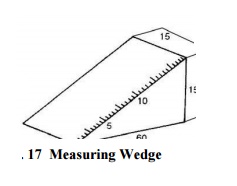

Warpage Test (IS:3495 (Part IV):

Warpage of the brick is measured with the help of a flat steel or glass surface

and measuring ruler graduated in 0.5 mm divisions or wedge of steel 60 × 15 ×

15 mm (Fig. 17 ). For warpage test, the sample consists of 10 bricks from a

lot.

Concave Warpage: The flat surface of the brick is placed along

the surface to be measured selecting the location that gives the greatest

deviation from straightness. The greatest distance of brick surface from the

edge of straightness is measured by a steel ruler or wedge.

Convex Warpage: The brick is

place on the plane surface with the convex surface in contact with the flat

surface and the distances of four corners of brick are measured from the flat

surface. The largest distance is reported as warpage.

The higher of the distance measured in concave and

convex warpage tests is reported as warpage. Efflorescence Test (IS: 3495

(Part III)): The ends of the brick are kept in a 150 mm diameter porcelain

or glass dish containing 25 mm depth of water at room temperature (20 o -30 o C)

till the entire water is absorbed or evaporated. The water is again filled to

25 mm depth in the dish and allowed to be absorbed by the brick or evaporated.

Presence of efflorescence is classified as below.

When the

deposit of efflorescence is imperceptible.

ht When the deposit of efflorescence

does not cover more than 10 per cent

he

exposed area of the brick.

derate When the deposit of efflorescence

is more than 10 per cent but less than

of the

exposed area of the brick.

When the

deposit of efflorescence is more than 50

per cent but the

vy osits

not powder

or flake away the brick surface.

ous When the deposits are heavy and

powder or flake away the brick surface.

The

specifications limit the efflorescence to be not more than moderate (10-50%) up

to class and not more than slight (< 10 per cent) for higher classes.

Related Topics