Chapter: Civil : Prestressed Concrete Structures : Design Concepts

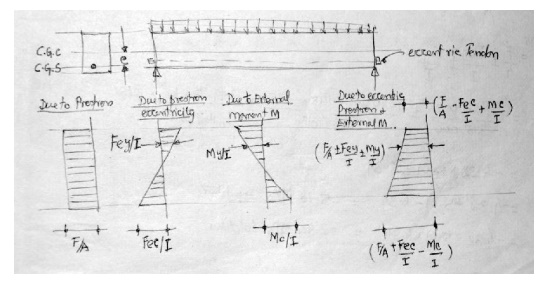

Prestressed Concrete Structures: Analysis of beam section- concept

Analysis of beam section - concept

Sign convention

1. Tension is (+)

2. Compression is (-)

Different concepts

Different concepts can be applied to

the analysis if PSC concrete beams, namely

1. Pre-stressing transforms concrete

into an elastic material.

2. Pre-stressing is a

combination of high-strength steel and concrete.

3. Pre-stress balances

loads.

Elastic material

This concept treats concrete as an

elastic material and is the most common among engineers. Here concrete is

visualized as being subjected to:

1. Internal pre-stress

2.

External loads.

So long as there are no cracks in the

section, the stresses, strains and deflections of the concrete due to the two

systems of forces can be considered separately and superimposed if needed.

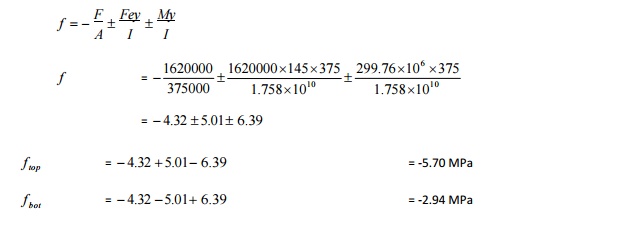

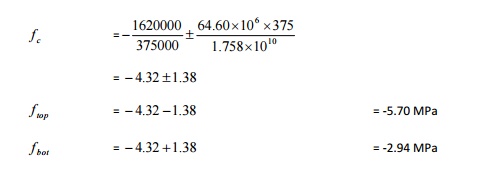

Due to a tensile pre-stressing force

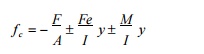

F, thee resulting stress at a section is given below.

The concrete stress at a section due

to pre-stress f is dependant only on the magnitude and location of pre-stress

at that section, ie., F and e, regardless of how the tendon profile varies

elsewhere along the beam.

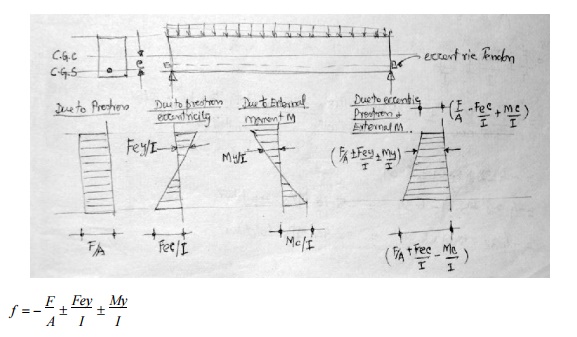

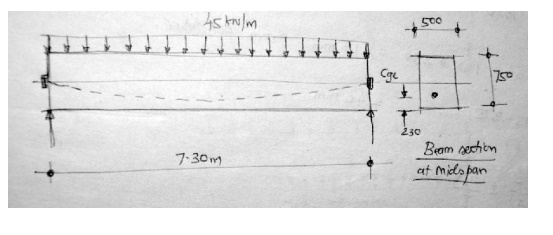

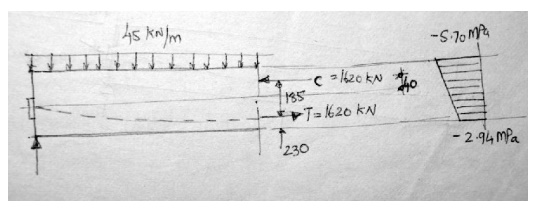

Ex 1

A pre-stress concrete rectangular

beam of size 500 mm x 750 mm has a simple span of 7.3 m and is loaded with a

udl of 45 kN/m including its self-weight. An effective pre-stress of 1620 kN is

produced. Compute the fiber stresses in concrete at mid-span section.

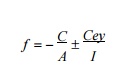

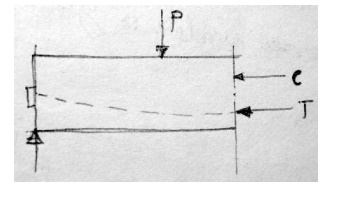

High strength steel and concrete

This considers the pre-stressed

concrete as combination of steel and concrete similar to RCC. Tension exists in

steel and compression in concrete. These two form a internal resisting couple

against external moment produced by loads.

[Note: Stresses are calculated with

force and eccentricity in concrete. e is the eccentricity of C, the compressive

force in concrete.]

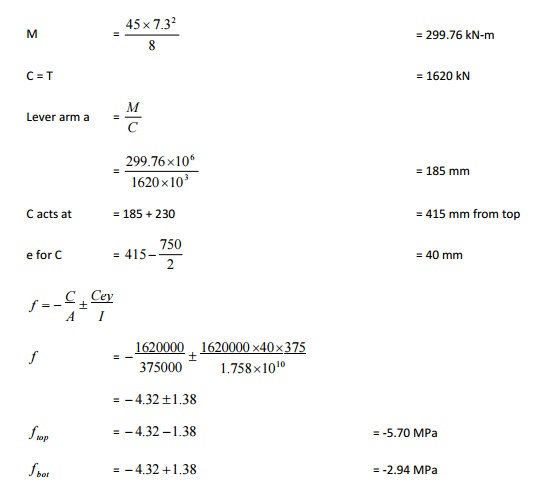

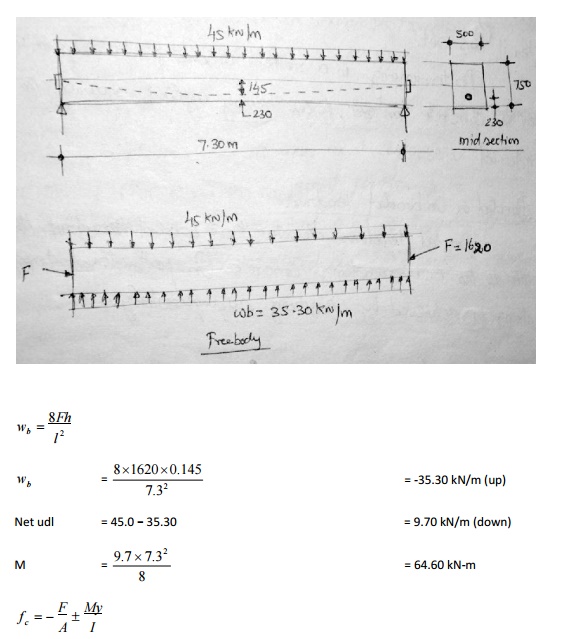

Ex 2

Solve Ex.1 using this concept.

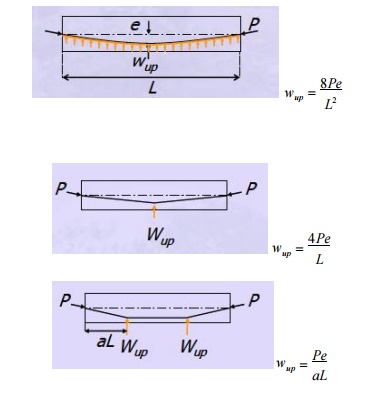

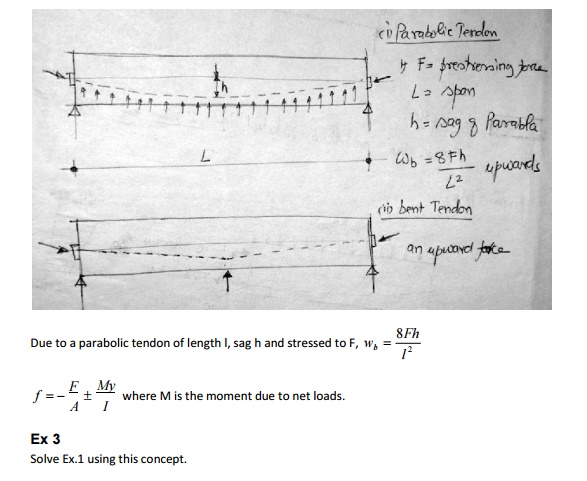

Load balancing

The effect of pre-stressing is

considered as the balancing of gravity loads so that the member under bending

will not be subjected to flexural stresses under a given loading condition.

Analysis of beam section for flexure

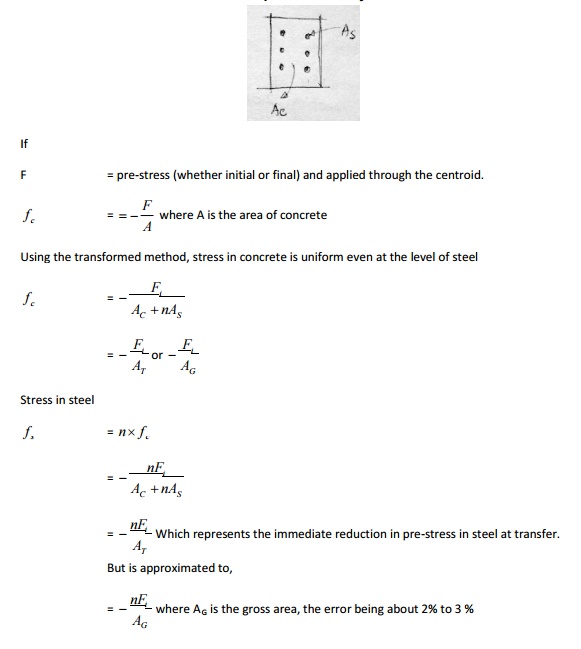

Stress in concrete and steel due to pre-stress only

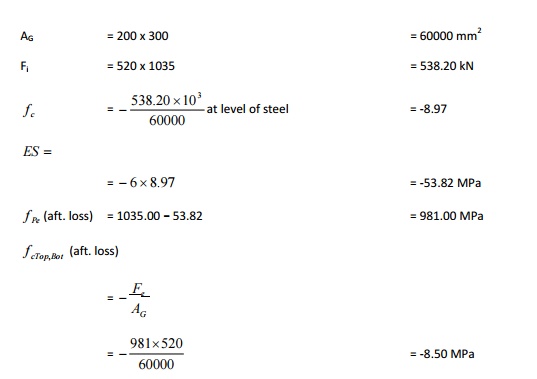

Example - Pre-tensioned member - concentric tendon

A pre-tensioned beam of size 200 mm x

300 mm is concentrically pre-stressed with 520 mm2 wires anchored to

bulkheads with a fi = 1035

MPa. Assuming n = 6, compute the stresses in concrete and steel immediately

after transfer due to pre-stress only.

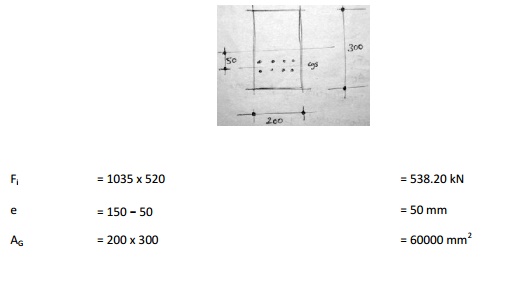

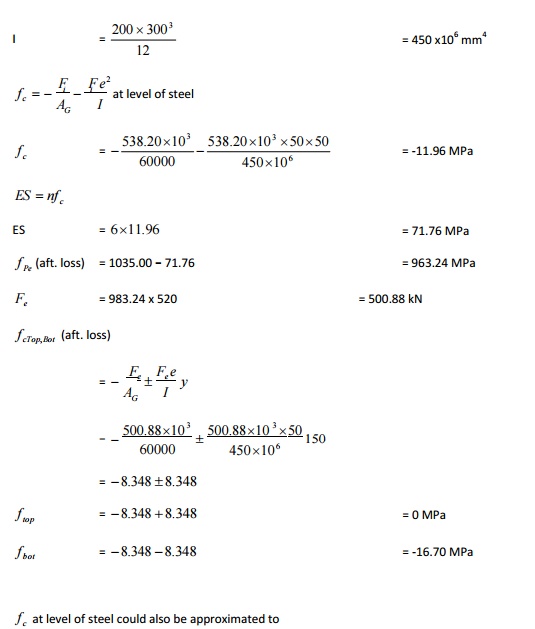

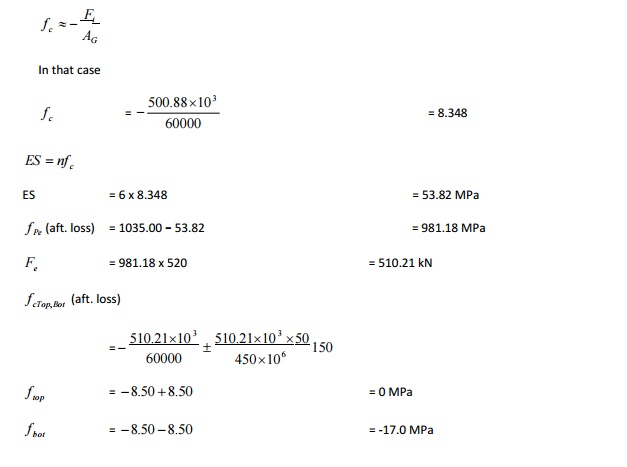

Example - Pre-tensioned member - eccentric tendon

A pre-tensioned beam of size 200 mm x

300 mm is eccentrically pre-stressed with 520 mm2 wires anchored to

bulkheads with a fi = 1035 MPa. The cgs is 100 mm above the bottom of the beam.

Assuming n = 6, compute the stresses in concrete and steel immediately after

transfer due to pre-stress only.

Which show that the approximate

method is fast and quite accurate.

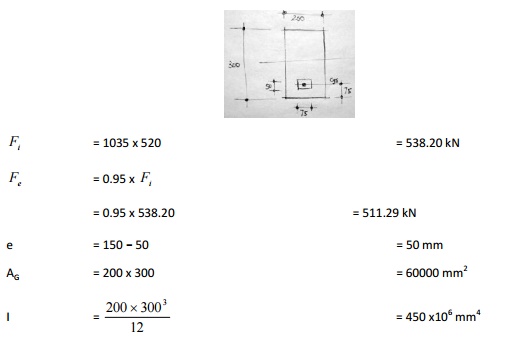

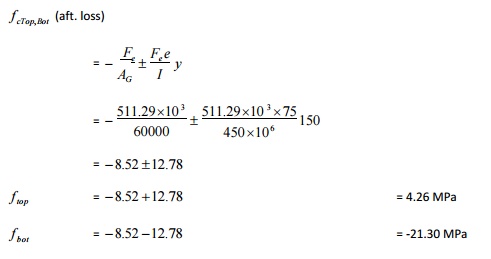

Example - Post-tensioned member - eccentric tendon

A post-tensioned beam of size 200 mm

x 300 mm is eccentrically pre-stressed with 520 mm2 wires stressed

to a fi = 1035 MPa. The cgs is 75 mm above the bottom of the beam.

Immediately after transfer the stress reduces by 5% owing to anchorage and

other losses. The size of the duct is 50 mm x 75 mm. Compute the stresses in

concrete and steel immediately after transfer due to pre-stress only.

Stress in concrete due to pre-stress & loads

Stresses in concrete produced by

external bending moment, whether due to the beam's self-weight or applied load

is:

The resulting stress in concrete due

to both the pre-stress and loads is:

Example - Post-tensioned member with loads

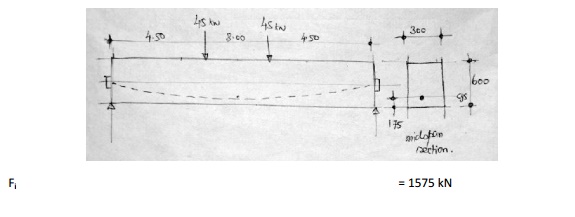

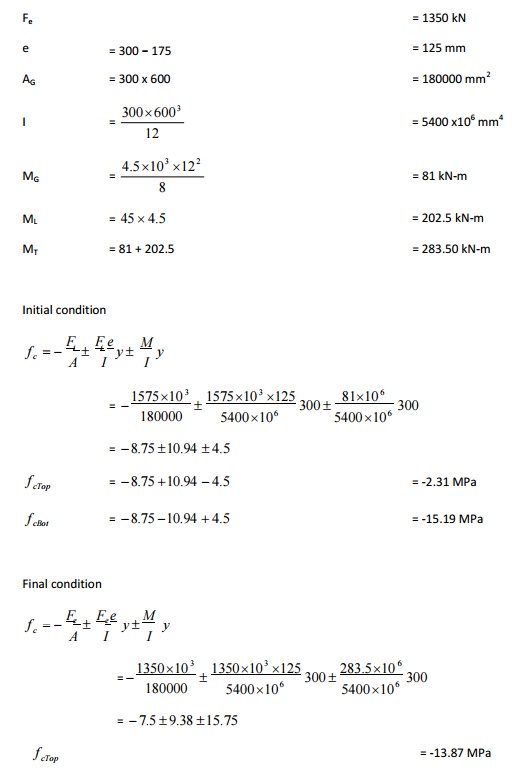

A post-tensioned beam of size 300 mm

x 600 mm and le = 12 m is pre-stressed with1575 kN which eventually reduces to

1350 kN due to losses. The cgs is 175 mm above the bottom of the beam. The beam

carries two live loads of 45 kN each in addition to its self-weight of 4.5

kN/m. Compute the extreme fiber stresses at mid-span for (a) initial condition

with full pre-stress and no live load and (b) pre-stress after losses with full

live load.

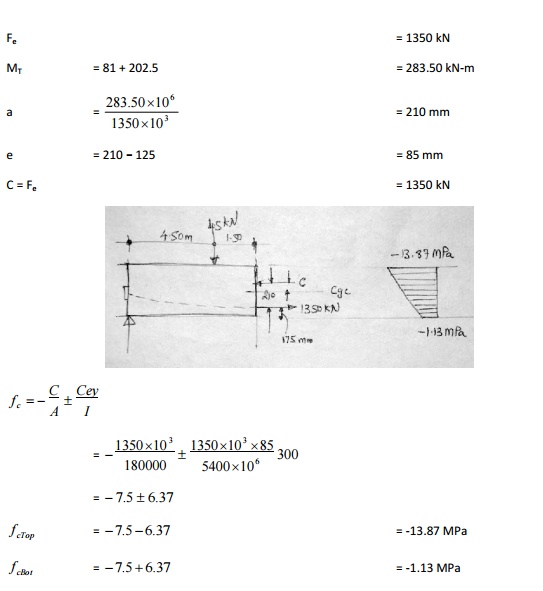

Example - Post-tensioned member with loads

Solve Ex by locating the center of pressure C for

concrete section.

Stress in steel due to loads

In RCC members, the lever arm between

the resultant compression and tension remains almost constant but the tension

in steel increases almost proportionately with increasing moment till yielding.

In pre-stress concrete resistance to

external bending moments is furnished by a lengthening of the lever arm between

the resisting forces C and T which remain relatively unchanged in magnitude.

After cracking, the stress in

pre-stressing steel increases rapidly with moment.

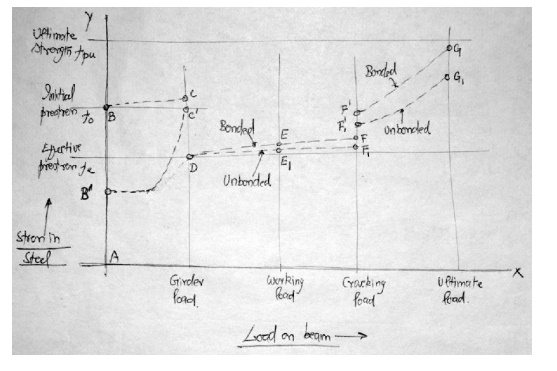

The following sketch explains the variations

of the stress in pre-stressing steel f p with increasing load.

The variations are shown for bonded

and un bonded tendons.

After the pre-stress is transferred

while the member is supported at the ends, the stress will tend to increase

from the value after losses f po due to the moment under self

weight. Simultaneously the stress will tend to drop due to the time dependent

losses such as creep, shrinkage and relaxation. The effective pre-stress after

time dependent losses is denoted as f pe

Due to the moment under service

loads, the stress in the pre-stressing steel will slightly increase from fpv

. The increase is more at the section of maximum moment in a bonded tendon as

compared to the increase in average stress for an un bonded tendon.

The stress in a bonded tendon is not

uniform along the length. Usually the increase in stress is neglected in the

calculations under service loads. If the loads are further increased, the

stress increases slightly till cracking.

After cracking, there is a jump of

the stress in the pre-stressing steel. Beyond that, the stress increases

rapidly with moment till the ultimate load. At ultimate, the stress is f pu

.

Similar to the observation for

pre-cracking, the average stress in an un bonded tendon is less than the stress

at the section of maximum moment for a bonded tendon.

As discussed above, at the section of

maximum moment, the stresses in the un bonded tendon increases more slowly than

that for bonded tendon. This is because any strain in an un bonded tendon will

be distributed throughout its entire length.

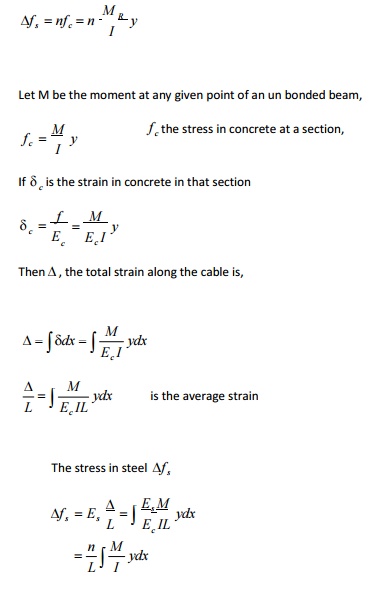

If MR is the resultant moment in at a

cross-section of a bonded beam and the beam deflects downwards, there is an

increase in steel stress due to this bending given by

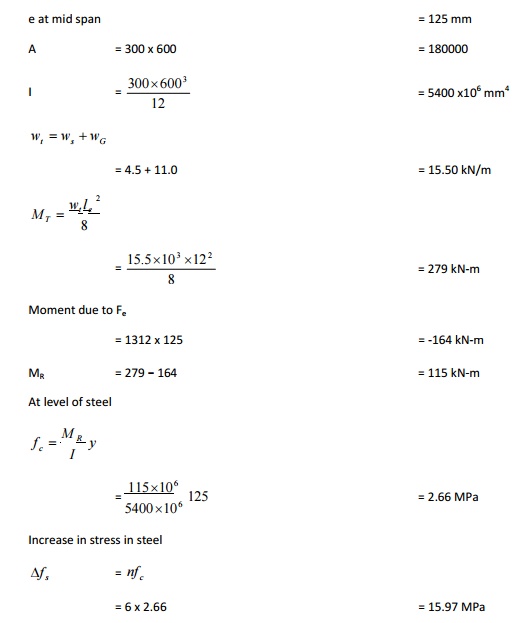

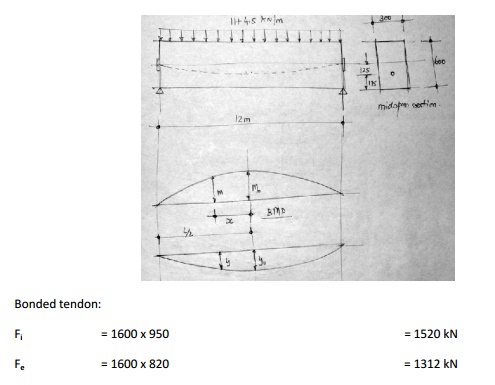

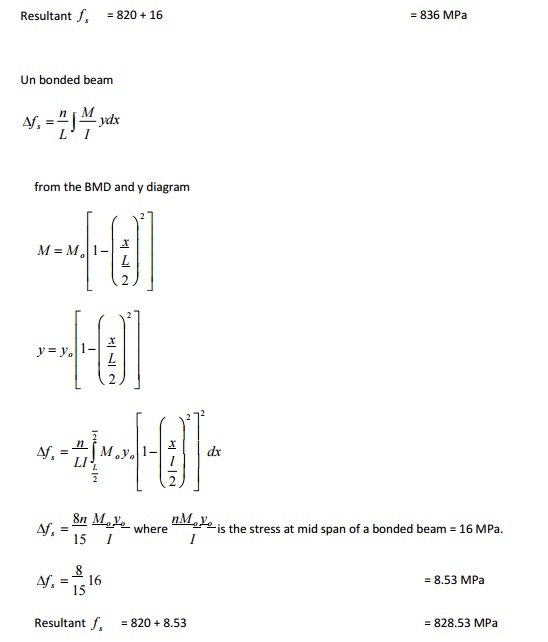

Example - stress in steel

A post-tensioned beam of span le = 12

m and size 300 mm x 600 mm, carries a superimposed load of 11 kN/m in addition

to its own weight of 4.5 kN/m. The initial pre-stress in steel is 950 MPa and

reduces to 820 MPa after all losses and assuming no bending in beam. The cable

of are 1600 mm2 is parabolic. N=6. Compute the stress in steel at

mid-span assuming (a) the steel is bonded by grouting and (b) the steel is un

bonded and entirely free to slip.

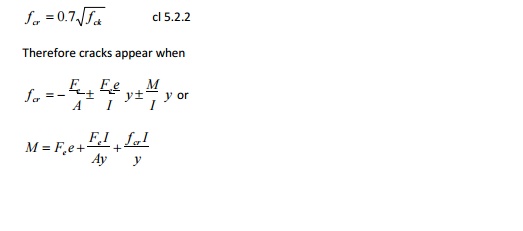

Cracking moment

Moments producing first crack in a

pre-stressed concrete beam, assuming cracks start when tensile stress in the

extreme fiber of concrete reaches its modulus of rupture, fcr ,

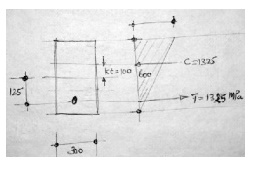

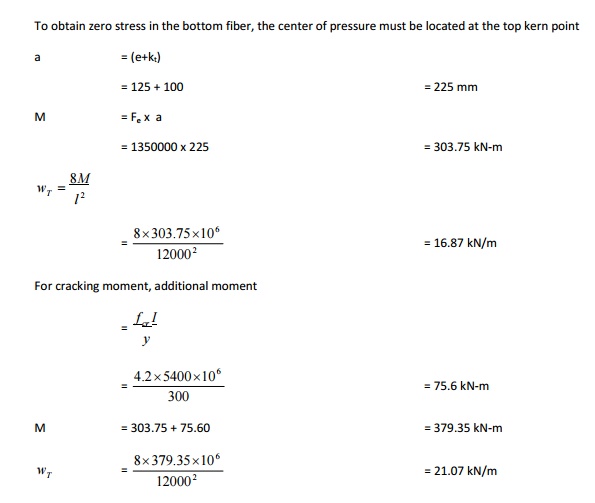

Example

For the problem in 6.3.1 compute the

total dead and live load that can be carried by the beam for (a) zero tensile

stress at bottom fiber and (2) cracking in the bottom fiber assuming f cr=

4.2MPa and Fe =

1350 kN.

Related Topics