Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Manufacturing Of Bricks

Manufacturing Of Bricks

Additives in the Manufacture of

Bricks

Certain additives such as fly

ash, sandy loam, rice husk ash, basalt stone dust, etc. are often required not

only to modify the shaping, drying and firing behaviour of clay mass, but also

to help conserve agricultural land and utilise waste materials available in

large quantities. These additives should, however, have a desirable level of

physical and chemical characteristics so as to modify the behaviour of clay

mass within the optimum range without any adverse effect on the performance and

durability. Some of the basic physio-chemical requirements of conventional

additives are as under:

Fly Ash: A waste

material available in large quantities from thermal power plants can be added

to alluvial, red, black, marine clays, etc. The fly ash contains

amorphous glassy material, mullite, haematite, magnetite, etc. and shows a

chemical composition similar to brick earths. These silicates also help towards

strength development in clay bodies on firing, when mixed in optimum proportion

depending on the physio-chemical and plastic properties of soils to be used for

brick making. The proportion of fly ash mixed as an additive to the brick earth

should be optimum to reduce drying shrinkage, check drying losses and to

develop strength on firing without bloating or black coring in fired product.

The crystallites present in the fly ash should comply with the resultant high

temperature phases in the finished product.

Sandy Loam: Addition of sandy loam is

often found effective in controlling the drying behaviour of highly

plastic soil mass containing expanding group of clay minerals. Sandy loam

should preferably have a mechanical composition as specified below. The

material should, however, meet the other requirement as well.

y micron) 0%

20 micron) 50%

d 0 micron) 60%

Rice Husk Ash: The ash should preferably

have unburnt carbon content in the range of 3-5% and

should be free from extraneous material. It can be used with plastic black

red soils showing excessive shrinkage.

Basalt Stone Dust: Basalt

stone occurs underneath the black cotton soil and its dust is a waste product

available in large quantity from basalt stone crushing units. The finer

fraction from basalt stone units is mixed with soil mass to modify the shaping,

drying and firing behaviour of bricks. The dust recommended for use as an

additive with brick earth should be fine (passing 1 mm sieve), free from coarse

materials or mica flakes and should be of non-calcitic or dolomitic origin.

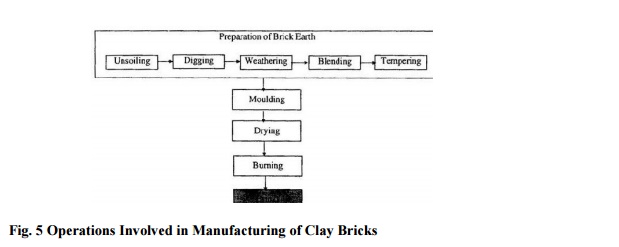

The operations involved in the manufacture of clay

bricks are represented diagrammatically in Fig.

Preparation of Brick Earth

It consists of the following operations.

Unsoiling: The soil

used for making building bricks should be processed so as to be free of gravel,

coarse sand (practical size more than 2 mm), lime and kankar particles, organic

matter, etc. About 20 cm of the top layer of the earth, normally containing

stones, pebbles, gravel, roots, etc., is removed after clearing the trees and

vegetation.

Digging: After

removing the top layer of the earth, proportions of additives such as fly ash,

sandy loam, rice husk ash, stone dust, etc. should be spread over the

plane ground surface on volume basis. The soil mass is then manually excavated,

puddled, watered and left over for weathering and subsequent processing. The

digging operation should be done before rains.

Weathering: Stones, gravels, pebbles,

roots, etc. are removed from the dug earth and the soil is heaped on

level ground in layers of 60-120 cm. The soil is left

in heaps and exposed to weather for at least one month in cases where such

weathering is considered necessary for the soil. This is done to develop

homogeneity in the mass of soil, particularly if they are from different

sources, and also to eliminate the impurities which get oxidized. Soluble salts

in the clay would also be eroded by rain to some extent, which otherwise could

have caused scumming at the time of burning of the bricks in the kiln. The soil

should be turned over at least twice and it should be ensured that the entire

soil is wet throughout the period of weathering. In order to keep it wet, water

may be sprayed as often as necessary. The plasticity and strength of the clay

are improved by exposing the clay to weather.

Blending: The earth is then mixed with

sandy-earth and calcareous-earth in suitable proportions to modify the

composition of soil. Moderate amount of water is mixed so as to obtain the

right consistency for moulding. The mass is then mixed uniformly with spades.

Addition of water to the soil at the dumps is necessary for the easy mixing and

workability, but the addition of water should be controlled in such a way that

it may not create a problem in moulding and drying. Excessive moisture content

may effect the size and shape of the finished brick

Tempering: Tempering consists of kneading

the earth with feet so as to make the mass stiff and plastics (by

plasticity, we mean the property which wet clay has of being permanently

deformed without cracking). It should preferably be carried out by storing the

soil in a cool place in layers of about 30 cm thickness for not less than 36

hours. This will ensure homogeneity in the mass

of clay for subsequent processing. For

manufacturing good brick, tempering is done in pug mills and the operation is

called pugging.

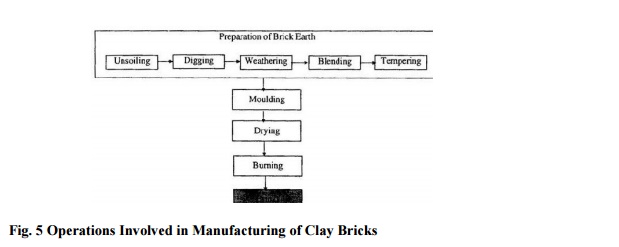

Pug mill

consists of a conical iron tube as shown in Fig. 6. The mill is sunk 60 cm into

the earth. A vertical shaft, with a number of horizontal arms fitted with

knives, is provided at the centre of the tube. This central shaft is rotated

with the help of bullocks yoked at the end of long arms. However, steam, diesel

or electric power may be used for this purpose. Blended earth along with

required water, is fed into the pug mill from the top. The knives cut through

the clay and break all the clods or lump-clays when the shaft rotates. The

thoroughly pugged clay is then taken out from opening provided in the side near

the bottom. The yield from a pug mill is about 1500 bricks.

Moulding

It is a process of giving a required shape to the brick from the prepared brick earth. Moulding may be carried out by hand or by machines. The process of moulding of bricks may be the soft-mud (hand moulding), the stiff-mud (machine moulding) or the dry- press process (moulding using maximum 10 per cent water and forming bricks at higher pressures). Fire-brick is made by the soft mud process. Roofing, floor and wall tiles are made by dry-press method. However, the stiff-mud process is used for making all the structural clay products.

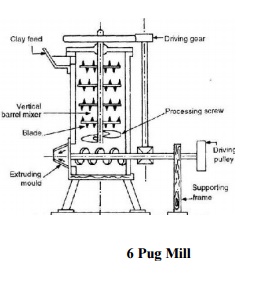

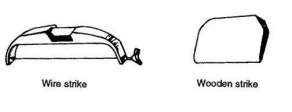

Hand

Moulding: A typical mould is shown in Fig. 7. Hand moulding is further

classified as ground moulding and table moulding

Ground Moulding: In this

process, the ground is levelled and sand is sprinkled on it. The moulded bricks

are left on the ground for drying. Such bricks do not have frog and the lower

brick surface becomes too rough. To overcome these defects, moulding blocks or

boards are used at the base of the mould. The process consists of shaping in

hands a lump of well pugged earth, slightly more than that of the brick volume.

It is then rolled into the sand and with a jerk it is dashed into the mould.

The moulder then gives blows with his fists and presses the earth properly in

the corners of the mould with his thumb. The surplus clay on the top surface is

removed with a sharp edge metal plate called strike (Fig. 8) or with a thin

wire stretched over the mould. After this the mould is given a gentle slope and

is lifted leaving the brick on the ground to dry.

Notes: (i) This method is adopted when a large and

level land is available.

(ii) To prevent the moulded bricks from sticking

to the side of the mould, sand is sprinkled on the inner sides of the mould, or

the mould may be dipped in water every time before moulding is done. The bricks

so produced are respectively called sand moulded and slop moulded bricks, the

former being better since they provide sufficient rough surface necessary for

achieving a good bond between bricks and mortar.

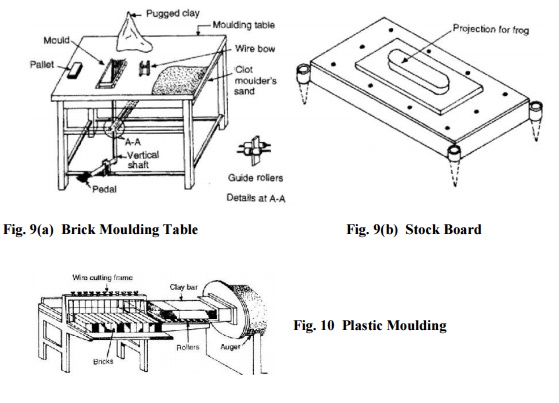

Table Moulding: The bricks are moulded on

stock boards nailed on the moulding table

(Fig. 9). Stock boards have the projection for forming the

frog. The process of filling clay in the mould is the same as explained above.

After this, a thin board called pallet is placed over the

mould. The mould containing the brick is then

smartly lifted off the stock board and inverted so that the moulded clay along

with the mould rests on the pallet. The mould is then removed as explained before

and the brick is carried to the drying site.

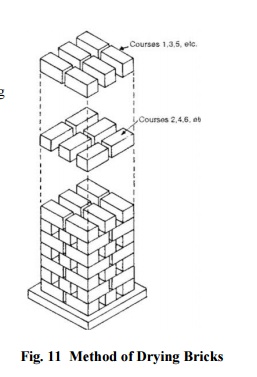

Machine Moulding can be

done by either of the following processes:

Plastic Method: The pugged, stiffer clay is forced

through a rectangular opening of brick size by means of an auger. Clay comes

out of the opening in the form of a bar. The bricks are cut from the bar by a

frame consisting of several wires at a distance of brick size as shown in Fig.

10. This is a quick and economical process.

Dry-press Method: The moist, powdered clay is fed

into the mould on a mechanically operated press, where it is subjected to high

pressure and the clay in the mould takes the shape of bricks. Such pressed

bricks are more dense, smooth and uniform than ordinary bricks. These are burnt

carefully as they are likely to crack.

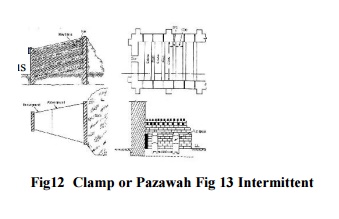

Drying

Green bricks contain about 7 - 30% moisture

depending upon the method of manufacture. Theobject of drying is to remove the

moistre to controlthe shrinkage and save fuel and time during burning.The

drying shrinkage is dependent upon pore spaceswithin the clay and the mixing

water. The additionof sand or ground burnt clay reduces shrinkage,increases

porosity and facilities drying. The moisturecontent is brought down to about 3

per cent underexposed conditions within three to four days. Thus,the strength

of the green bricks is increased and the bricks can be handled safely. Clay

products can be dried in open air driers or in artificial driers. The

artificial driers are of two types, the hot floor drier and the tunnel drier.

In the former, heat is applied by a furnance placed at one end of the drier or

by exhaust steam from the engine used to furnish power and is used for fire

bricks, clay pipes and terracotta. Tunnel driers are heated by fuels

underneath, by steam pipes, or by hot air from cooling kilns. They are more

economical than floor driers. In artificial driers, temperature rarely exceeds

120 o C. The time varies from one to three days. In developing countries, bricks

are normally dried in natural open air driers (Fig. 11). They are stacked on

raised ground and are protected from bad weather and direct sunlight. A gap of

about 1.0 m is left in the adjacent layers of the stacks so as to allow free

movement for the workers.

Burning

The burning of clay may be divided into three main stages.

Dehydration (400-650 o C):

This is also known as water smoking stage. During dehydration,

(1) the water

which has been retained in the pores of the clay after drying is driven off and

the clay loses its plasticity, (2) some of the carbonaceous matter is burnt,

(3) a portion of sulphur is distilled from pyrites. (4) hydrous minerals like

ferric hydroxide are dehydrated, and (5) the carbonate minerals are more or

less decarbonated. Too rapid heating causes cracking or bursting of the bricks.

On the other hand, if alkali is contained in the clay or sulphur is present in

large amount in the coal, too slow heating of clay produces a scum on the

surface of the bricks.

Oxidation Period (650-900 o C):

During the oxidation period, (1) remainder of carbon is eliminated and,

(2) the

ferrous iron is oxidized to the ferric form. The removal of sulphur is

completed only after the carbon has been eliminated. Sulphur on account of its

affinity for oxygen, also holds back the oxidation of iron. Consequently, in

order to avoid black or spongy cores, oxidation must proceed at such a rate

which will allow these changes to occur before the heat becomes sufficient to

soften the clay and close its pore. Sand is often added to the raw clay to

produce a more open structure and thus provide escape of gases generated in

burning.

Vitrification-To

convert the mass into glass like substance - the

temperature ranges from 900- 1100 o C

for low melting clay and 1000-1250 o C for high melting

clay. Great care is required in cooling the bricks below the cherry red heat in

order to avoid checking and cracking. Vitrification period may further be

divided into (a) incipient vitrification, at which the clay has softened

sufficiently to cause adherence but not enough to close the pores or cause loss

of space-on cooling

the material cannot be scratched by the knife; (b) complete vitrification, more

or less well-marked by maximum shrinkage; (c) viscous vitrification, produced

by a further increase in temperature which results in a soft molten mass, a

gradual loss in shape, and a glassy structure after cooling. Generally, clay

products are vitrified to the point of viscosity. However, paving bricks are

burnt to the stage of complete vitrification to achieve maximum hardness as

well as toughness.

Burning of bricks is done in a

clamp or kiln. A clamp is a temporary structure whereas kiln is a permanent

one.

Burning in Clamp or Pazawah: A typical

clamp is shown in Fig. 2.9. The bricks and fuel are placed in alternate

layers. The amount of fuel is reduced successively in the top layers. Each

brick tier consists of 4-5 layers of bricks. Some space is

left between bricks for free circulation of hot gasses. After 30 per cent

loading of the clamp, the fuel in the lowest layer is fired and the remaining

loading of bricks and fuel is carried out hurriedly. The top and sides of the

clamp are plastered with mud. Then a coat of cowdung is given, which prevents

the escape of heat. The production of bricks is 2-3 lacs

and the process is completed in six months. This process yields about 60 per

cent first class bricks.

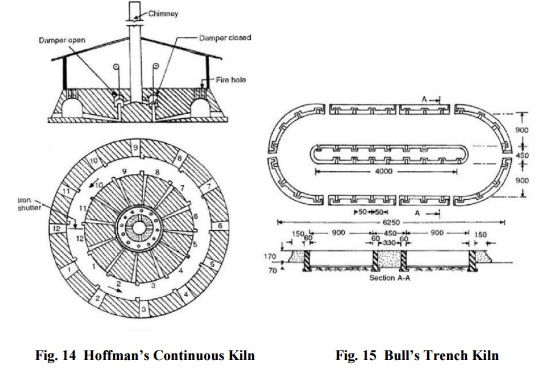

Kiln

Burning: The kiln used for burning bricks may be underground, e.g.

Bull's trench kiln or overground, e.g. Hoffman's kiln. These may be

rectangular, circular or oval in shape. When the process of burning bricks is

continuous, the kiln is known as continuous kiln, e.g. Bull's trench and

Hoffman's kilns.

On the other hand if the process of burning bricks

is discontinuous, the kiln is known as intermittent kiln. Intermittent Kiln:

The example of this type of an over ground, rectangular kiln is shown in Fig.

2.10. After loading the kiln, it is fired, cooled and

Kiln

unloaded and then the next loading is done. Since

the walls and sides get cooled during reloading and are to be heated again

during next firing, there is wastage of fuel.

Continuous Kiln: The

examples of continuous kiln are Hoffman's kiln (Fig. 2.11) and Bull's trench

kiln (Fig. 2.12). In a continuous kiln, bricks are stacked in various

chambers wherein the bricks undergo different treatments at the same time. When

the bricks in one of the chambers is fired, the bricks in the next set of

chambers are dried and preheated while bricks in the other set of chambers are

loaded and in the last are cooled.

Note: In

the areas where black cotton soil occur, a more elaborate method of processing

is

followed. The clay, which may be black or a

mixture of black and yellow, is first washed free of the

lime kankar in the 'GHOL' tanks. The slurry is then run off to the setting

tanks. After 3-4

days when the clay has settled down, the

supernatant water is bucketed off. Opening material like powdered grog of fine

coal ash (passing 2.00 mm sieve), which opens up the texture of clay mass, is

then added in predetermined proportions. This is usually 30 to 40 per cent of

the mass of clay. A solution of 0.5 per cent sodium chloride may also be added

at this stage to prevent lime bursting. The clay is then thoroughly mixed with

the opening materials added and allowed to dry further for a period of 3-4 days

till the mix attains the correct moulding consistency. Grog is prepared by

lightly calcining lumps of black cotton soil (about 10 to 15 cm dia.) in a

clamp at about 700 o to 750 o C. Coal ash, fire wood, brambles, etc. may be used

as fuel. The fuel and clay lumps are arranged in alternate layers in the clamp.

After calcination the clay is pulverized in a machine, such as disintegrator, a

hammer mill or a pan-mill to a fineness of less than 2.0 mm.

Related Topics