Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Classification Of Bricks

Classification Of Bricks

On Field Practice

Clay bricks are classified as

first class, second class, third class and fourth class based on their physical

and mechanical properties.

First Class Bricks

1. These are

thoroughly burnt and are of deep red, cherry or copper colour.

2. The

surface should be smooth and rectangular, with parallel, sharp and straight

edges and square corners.

3. These

should be free from flaws, cracks and stones.

4. These

should have uniform texture.

5. No

impression should be left on the brick when a scratch is made by a finger nail.

6. The

fractured surface of the brick should not show lumps of lime.

7. A

metallic or ringing sound should come when two bricks are struck against each other.

9. Water absorption should be 12-15% of

its dry weight when immersed in cold water for 24 hours. The crushing strength

of the brick should not be less than 10 N/mm2. This limit varies

with different Government organizations around the country.

Uses: First class bricks are recommended for

pointing, exposed face work in masonry structures, flooring and reinforced

brick work.

Second Class Bricks are

supposed to have the same requirements as the first class ones except that

1. Small

cracks and distortions are permitted.

2. A little

higher water absorption of about 16-20% of

its dry weight is allowed.

3. The

crushing strength should not be less than 7.0 N/mm2.

Uses: Second class bricks are

recommended for all important or unimportant hidden masonry works and centering

of reinforced brick and reinforced cement concrete (RCC) structures.

Third Class Bricks are

underburnt. They are soft and light-coloured producing a dull sound when struck

against each other. Water absorption is about 25 per cent of dry weight.

Uses : It is used for building temporary structures.

Fourth Class Bricks are

overburnt and badly distorted in shape and size and are brittle in nature. Uses:

The ballast of such bricks is used for foundation and floors in lime concrete

and road metal.

On Strength

The Bureau of Indian Standards

(BIS) has classified the bricks on the basis of compressive strength and is as

given in Table 2

Table 2 Classification of Bricks based on

Compressive Strength (IS: 1077)

Class : Average compressive

strength not less than (N/mm2)

35 35.0

30 30.0

25 25.0

20 20.0

17.5 17.5

15 15.0

12.5 12.5

10 10.0

7.5 7.5

5 5.0

3.5 3.5

Notes: 1. The burnt clay

bricks having compressive strength more than 40.0 N/mm 2 are known

as heavy duty bricks and are used for heavy duty structures such as bridges,

foundations for industrial buildings, multistory buildings, etc. The water

absorption of these bricks is limited to 5 per cent.

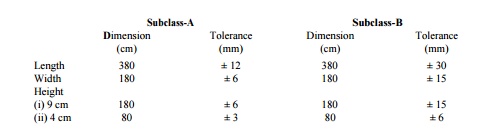

2. Each

class of bricks as specified above is further divided into subclasses A and B

based on tolerances and shape. Subclass-A bricks should have smooth rectangular

faces with sharp corners and uniform colour. Subclass-B bricks may have

slightly distorted and round edges.

Subclass-A Subclass-B

Dimension(cm) Tolerance(mm) Dimension(cm) Tolerance(mm)

Length 380 ±

12 380 ± 30

Width 180 ±

6 180 ± 15

Height

(i)

9 cm 180 ± 6 180 ± 15

(ii)

4 cm 80 ± 3 80 ± 6

On the Basis of Use

Common Brick is a

general multi-purpose unit manufactured economically without special reference

to appearance. These may vary greatly in strength and durability and are

used for filling, backing and in walls where appearance is of no consequence.

Facing Bricks are made

primarily with a view to have good appearance, either of colour or texture or

both. These are durable under severe exposure and are used in fronts of

building walls for which a pleasing appearance is desired.

Engineering Bricks are

strong, impermeable, smooth, table moulded, hard and conform to defined limits

of absorption and strength. These are used for all load bearing structures.

On the Basis of Finish

Sand-faced Brick has

textured surface manufactured by sprinkling sand on the inner surfaces of the

mould.

Rustic Brick has mechanically textured

finish, varying in pattern.

On the Basis of Manufacture

Hand-made: These bricks are hand moulded.

Machine-made: Depending

upon mechanical arrangement, bricks are known as wire-cut bricks-bricks

cut from clay extruded in a column and cut off into brick sizes by wires;

pressed-bricks-when bricks are manufactured from stiff

plastic or semi-dry clay and pressed into moulds; moulded bricks-when

bricks are moulded by machines imitating hand mixing.

On the Basis of Burning

Pale Bricks are underburnt

bricks obtained from outer portion of the kiln. Body Bricks are well

burnt bricks occupying central portion of the kiln.

Arch

Bricks are overburnt also known as clinker bricks obtained from inner

portion of the kiln.

On the Basis of Types

Solid: Small

holes not exceeding 25 per cent of the volume of the brick are permitted;

alternatively, frogs not exceeding 20 per cent of the total volume are

permitted.

Perforated: Small holes may exceed 25 per

cent of the total volume of the brick.

Hollow: The total

of holes, which need not be small, may exceed 25 per cent of the volume of the

brick. Cellular: Holes closed at one end exceed 20 per cent of the

volume.

Note:

Small holes are less than 20 mm or less than 500 mm2 in cross

section.

Related Topics