Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Production Planning and Control Systems

Just ln Tirne Production Systems

JUST IN TIME

PRODUCTION SYSTEMS

Just-in-time (JIT) production systems were

developed in Japan to minimize inventories,

especial 1)' WlP. WIP

and other types of inventory are seen by the Japanese as waste that should be

minimized or eliminated, The ideal just-in-time

production system produces and delivers exactly the required number of each

component to the downstream operation in the manufacturing sequence just at the

time when that component is needed. Each component is delivered "just in

time." This delivery discipline minimizes WIP and manufacturing lead time

as well as the space and money invested in WIP, The JIT discipline can be applied

not only to production operations but to supplier delivery operations as well

Whereas

the development of lIT production systems is largely credited to the Japanese,

the philosophy of JIT has been adopted by many U.S. manufacturing firms. Other

terms have sometimes been applied to the American practice of lIT to suggest

differences with the Japanese practice. For example, continuous flow manufacturing is a widely used term in the United

States that denotes a lIT style of production operations. Prior to lIT, the

traditional U.S. practice might be described as a just In case"

philosophy. that is, to hold large in process inventories to cope with

production problems such as late deliveries of components, machine breakdowns. Defective components, and

wildcat strikes,

The JIT

production discipline has shown itself to be very effective in high volume

repetitive operations, such as those found in the automotive industry (6J, The potential for wrp accumulation in this type of

manufacturing is significant due to the large quantities of products made and the large

numbers of components per product.

The

principal objective of JIT is to reduce inventories, However, inventory

reduction cannot simply be mandated to happen. Certain requisites must be in

place for a JlT production system to operate successfully. They are: (I) a pull

system of production control, (2) small batch sizes and reduced setup times,

and (3) stable and reliable production operations. We discuss these requisites

in the following sections.

Pull

System of Production Control

JIT is

based on a pull system of production

control, in which the order to make and deliver parts at each workstation in

th", production sequence comes from the downstream station that uses those

parts. When the supply of parts at a given workstation is about to be

exhausted. that station orders the upstream station to replenish the supply.

Only on receipt of this order is the upstream station authorized to produce the

needed parts. When this procedure is repeated at each workstation throughout

the plant, it has the effect of pulling parts through the production system. By

comparison, in a push system of

production control, parts at each workstation are produced irrespective of the

immediate need for the parts at its respective downstream station. In effect, this

production discipline pushes parts through the plant. The risk in a push system

is that more work gets scheduled in the factory than it can handle, resulting

in large queues of parts in front of machines. The machines are unable to keep

up with arriving work. and the factory becomes overloaded. A poorly planned MRP

based production planning system that does not include capacity planning runs

this risk.

One way

to implement a pull system is to use kanbans, The word kanban (pronounced kahn-bahn ) means "card" in Japanese,

The Kanban system of production

control, developed and made famous by Toyota, the Japanese automobile company,

is based on the use of cards that authorize (1) parts production and (2) parts

delivery in the plant. Thus, there are two types of kanbans: (1) production

kanuans and (2) transport kanbans. A production

kanban (P-kanban) authorizes the

upstream station to produce a batch of parts. As they are produced. the parts are placed in

containers. so the batch quantity is just sufficient to fill the container.

Production of more than this quantity of parts is not allowed in the kauban

system. A transport kanbon (T-kanban)

authorizes transport of the container of parts to the downstream station.

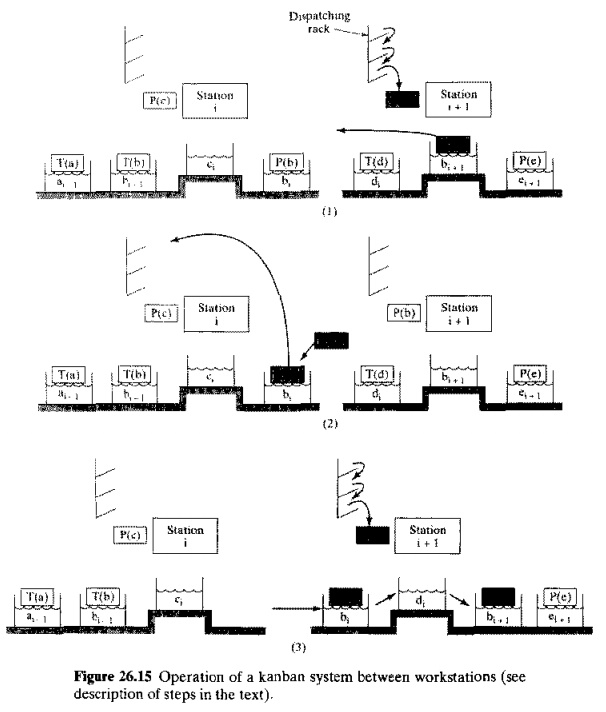

Let us

describe the operation of a kanban system with reference to Figure 26.15. The

workstations shown in the figure (station i and

station i + 1) are only two in a sequence of

multiple stations upstream and downstream. The flow of work is from station i to station

i + 1. The

sequence of steps in the kanban pull system is as follows (our numbering

sequence is coordinated with Figure 26.15): (1) Station i + 1 removes the next P-kanban from

the dispatching rack This P-kanban authorizes the station to process a container

of part b. A material handling worker removes the T-kanban from the incoming

container and takes it back to station i.

(2) At station i, the worker finds a

container of part b, removes the P-kanhan and replaces it with the T-kanban. He

then puts the P-kanban in the dispatching rack at station i. (3) The P-kanban for part b at

station i authorizes station i to process a new container of

part b: however, it must wait its turn in the rack for the other Pkanbans ahead

of it. Scheduling of work at each station is determined by the order in which

the production kanbans are placed in the dispatching rack. The container of

part b that was at station i is moved

to station i + 1, as authorized by the 'T-kanban.

Meanwhile, processing of the b parts at station i + 1 has

been completed, and that station removes the next P-kanban from the dispatching

rack and begins processing that container of parts (part d as indicated in our

figure).

As

mentioned, stations i and i + 1 are only two sequential

stations in a longer sequence, All other pairs of sequential stations operate

according to the same kanban pull system. This production control system avoids

unnecessary paperwork. The kanban cards are used over and over again instead of

generating new production and transport orders every cycle. Although

considerable labor is involved in material handling (moving cards and

containers between stations), this is claimed to promote teamwork and

cooperation among workers.

Small

Batch Sizes and Reduced Setup Times

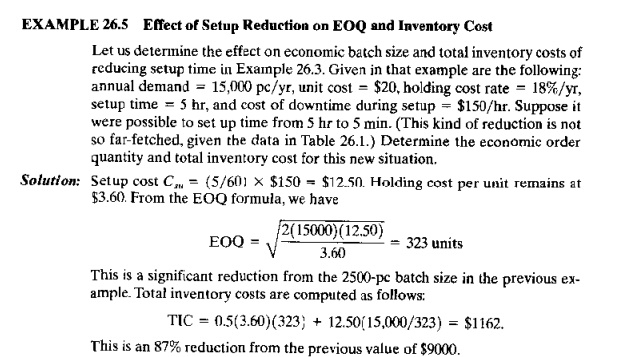

To

minimize WIP inventories in manufacturing, batch size and setup time must be

minimized. The relationship between batch size and setup time is given by the EOQ formula, Eq. (2fi 5). In

our mathematical model for total inventory cost, Eq. (26.1). from which the EOQ

formula is derived, average inventory level is equal to one half the batch

size. To reduce average inventory level, batch size must be reduced. And to

reduce batch size, setup cost must be reduced. This means reducing setup times.

Reduced setup times permit smaller batches and lower WIP levels. Methods for

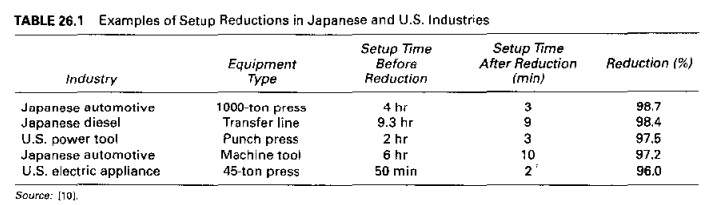

reducing setup time were pioneered by the Japa?ese during the 1960s and 1970s.

U.S. manufacturing firms have also adopted setup reduction methods. Results of

the efforts are sometimes dramatic. Examples of setup reductions in Japanese

and U.S. industries are reported by Suzaki, and we present some of these in

Table 26.1.

Setup

time reductions result from a number of basic approaches that are best

described as industrial engineering methods improvements. These approaches

include (sourcc,:)·

Figure 26.15 Operation of a kanban

system between workstations (see description

of steps in the text)

Separate the work elements that comprise

the setup procedure into two categories:

internal elements,

those that must

be done during the machine

stoppage, and

external

dements, those that can be done while the previous job is still running.

Design

the setup tooling [e.g., die, fixture, mold) and plan the setup method to

permit as much of the changeover procedure as possible to consist of external

work elements.

Use time

and motion study to reduce the internal work elements to the fewest possible.

Eliminate or minimize

adjustments in the setup.

Adjustments are time consuming.

Use

quickacting clamping devices

instead of bolts and nuts.

Develop permanent

solutions for problems that cause

delays in the setup.

Schedule

batches of similar part styles in sequence to minimize the magnitude of changes

required in the setup.

Use group

technology and cellular manufacturing it possible so that similar part styles

are produced on the same equipment.

Design

modular fixtures consisting of a base unit plus insert tooling that can be

quickly changed for each new part style.

Stable

and Reliable Production Operations

Other

requirements for a successful JIT production systems include: (1) stable

production schedules, (2) on-time delivery, (3) defect-free components and

materials, (4) reliable production equipment. (5) a workforce that is capable,

committed, and cooperative, and (6) a dependable supplier base.

Stable

Schedule. Production must flow as smoothly as possible, which means minimum

perturbations from the fixed schedule. Perturbations in downstream operations

tend to be magnified in upstream operations. A 100/,change in final assembly

may translate into a 50Ll:. change

in parts production operations due to overtime, unscheduled setups, variations from

normal work procedures. and other exceptions, By maintaining a constant MPSS

over time, smooth work flow is achieved. and disturbances in production arc minimized.

On

Time Delivery, Zero Defects, and Reliable Equipment. Just-in-time

production requires near perfection in on-time delivery, parts quality, and

equipment reliability, Because of the small lot sizes used in JIT. parts must

be delivered before stock-outs occur at downstream stations. Otherwise. these

stations are starved for work. and production must be stopped

JIT

requires high quality in every aspect of production. If defective parts are

produced. they cannot be used in subsequent processing or assembly stations,

thus interrupting work at those stations and possibly stopping production. Such

a severe penalty forces a discipline of very high quality levels (zero defects)

in parts fabrication. Workers are trained to inspect their own output to make

sure it is right before it goes to the next operation. In effect. this means

controlling quality during production rather than relying on in specters to

discover the defects later. The Japanese use the word Jidoka in their quality control procedures. Roughly translated, it

means "stop everything when something goes wrong"

JIT also

requires highly reliable production equipment. Low WIP leaves little room for

equipment stoppages. Machine breakdowns cannot be tolerated in a JIT production

system. The equipment must he "designed for reliability." and the

plant that operates the equipment must have a well-planned preventive

maintenance program.

Workforce

and Supplier Base. Workers in a JIT production system must be cooperative.

committed, and cross-trained. Small batch sizes means that workers must be

willing and able to perform a variety of tasks and to produce a variety of pan

styles at their workstations. As indicated above, they must be inspectors as

well as production workers to ensure the quality of their own output. They must

be able to deal with minor technical problem, that may be experienced with the

production equipment so that major breakdowns are avoided.

The

suppliers of raw materials and components to the company must be held to the

same standards of ontime delivery, zero defects, and other JIT requirements as

the company itself. New policies in dealing with vendors are required for JlT.

These polices include: (I) reducing the total number of suppliers, thus

allowing the remaining suppliers to do more business: (2) entering into long term

agreements and partnerships with suppliers. so that suppliers do not have to

worry about competitively bidding for every order;

(3)

establishing quality and delivery standards and selecting suppliers on the

basis of their capacity to meet these standards; (4) placing employees into

supplier plants to help those suppliers develop their own JIT systems; and (5)

selecting parts suppliers that are located near the company's final assembly

plant to reduce transportation and delivery problems.

Related Topics