Textiles and Dress Designing - Grain | 12th Textiles and Dress Designing : Chapter 7 : Identification of Fabrics and Preliminary Stitches in Garment Construction

Chapter: 12th Textiles and Dress Designing : Chapter 7 : Identification of Fabrics and Preliminary Stitches in Garment Construction

Grain

Grain

This is the term that explains the direction in which the fabric

is woven. It determines greatly by the way the fabric falls on the object or

the wearer. Understanding the grain helps in minimising the wastage and to

create interesting fullness effects on the garment. Grain refers to the

alignment of warp and weft yarns inside a fabric. When the fabric is selected

for construction the grain line is analysed. When grain is not in the proper

angle steps are taken to make it right. Also, diagonal grain is chosen when the

design requires more flexibility for good fit or fullness for decoration. The

common type of grain seen in garments is the straight grain. The main reason

for this is, to get full strength for the garment which can be obtained when

the garment is cut in the same direction as it was constructed. Apart from

this, the perfectly twisted warp yarns that work like a skeleton on the fabric

is very strong. The combination of that warp along with the weft will enable

good compaction and better properties when cutting a garment pattern. In order

to check if the fabric is on proper grain, one thread can be ravelled from

selvedge to selvedge and then the fabric is folded on half. If this can create

neat edge in the bottom, it is said that the material has been laid on proper

grain. There are different types of grain which are explained below:

1. On Grain

Lengthwise grain means the yarn in the fabric runs in the length

of the fabric and is parallel to the selvage. Crosswise grain has threads that

are perpendicular to the selvage of the fabric. The term on grain refers to the

length and crosswise thread being right angle to each other. This is very basic

in woven fabric as they are made by warp and weft interlaced at right angle to

each other.

2. Off Grain

When the warp and weft threads are not exactly at the right

-angled ways, they are termed to be in off grain. This is usually a defect and

methods are available to set the grain to the on-grain line.

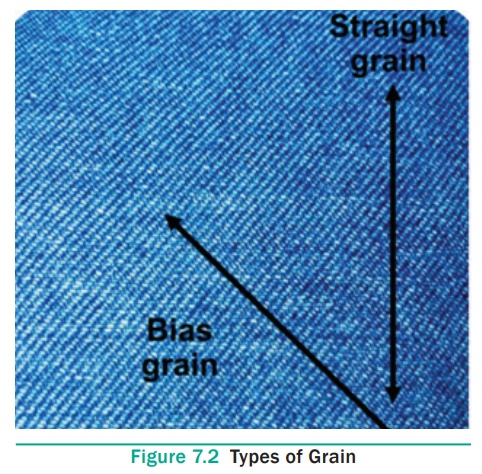

3. Bias Grain

When the garment pattern is cut at 45 degrees it is called bias

grain. This has a good drape as it is taken in the diagonal way. Further

extending of the pattern tends to increase the fall of the fabric and gives

beautiful wavy effect.

4. On Grain Print

This is when the print is neatly lined up with the warp yarns and

is parallel to the selvedge. It is on grain print and results in a neat look of

the design on a fabric.

5. Off Grain Print

In contrast to the above on grain print, off grain is the printed

set of design which is not parallel to the selvedge. This can be considered as

a defect in printing as it directly implies poor quality in printing.

It is also important to remember that when the textile material is

made in a weaving loom or a knitting machine it will be in the perfect grain

only. During the various textile processes like washing, calendaring, scouring,

mercerisation the selvedge are held tight resulting change in the grain lines.

When the grain line is not maintained in the way it should be done, there are

chances for the fabric to lose shape, sag and even be uncomfortable to wear.

Related Topics