Chapter: Mechanical : Kinematics of Machinery : Friction in the Machine Elements

Friction in the Machine Elements

FRICTIONIN THE MACHINE ELEMENTS

1 Surface contacts:

·

Basic laws of friction

·

Pivot and collar, introducti on and types.

·

Problem on flat pivot, Problems on conical pivot.

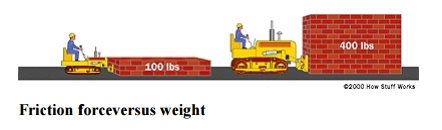

Friction

Friction is

a measure of how hard it is to slide one object over another. Take a look at the

figure below. Both of the blocks are made

from the same material, but one is heavier. I think we all know which one will be

harder for the bulldozer to push.

Friction force versus weight

To

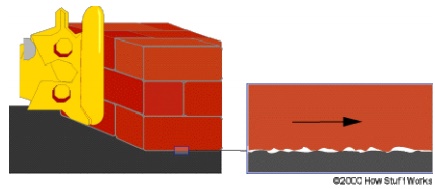

understand why this is, let's take a

close look at one of the blocks and the

table:

Because friction exists at the microscopic level,

the amount of force it takes to move a given block is proportional to that

block's weight.

Even though

the blocks look smooth to the naked eye, they are actually quite rough at the

microscopic level. When you set the block down on the table, the little peaks

and valleys get squished together, and some of them may actually weld together.

The weight of the heavier block causes it to squish together more, so it is

even harder to slide. Different materials have different microscopic

structures; for instance, it is harder to slide rubber against rubber than it

is to slide steel against steel. The type of material determines the

coefficient of friction, the ratio of the force required to slide the block to

the block's weight. If the coefficient were 1.0 in our example, then it would

take 100 pounds of force to slide the 100-pound (45 kg) block, or 400 pounds (180

kg) of force to slide the 400-pound block. If the coefficient were 0.1, then it

would take 10 pounds of force to slide to the 100-pound block or 40 pounds of

force to slide the 400-pound block.

So the

amount of force it takes to move a given block is proportional to that block's

weight. The more weight, the more force required. This concept applies for

devices like brakes and clutches, where a pad is pressed against a spinning

disc. The more force that presses on the pad, the greater the stopping force.

FRICTION

Dry friction – Friction in screw jack – Pivot and

collar friction - Plate clutches - Belt and rope drives - Block brakes, band

brakes.

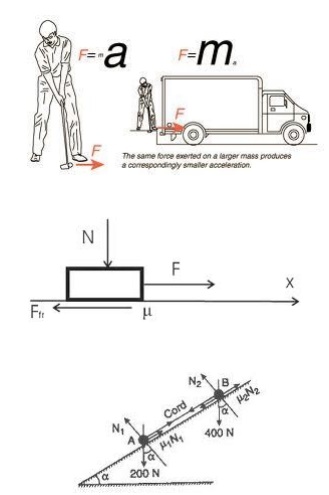

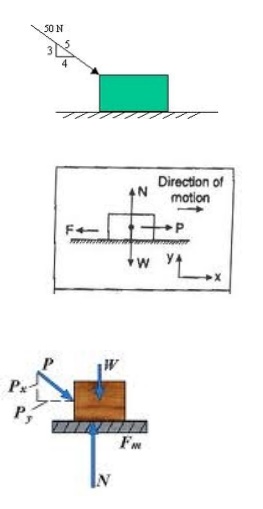

Friction:

The opposing force which acts in the opposite

direction of the movement of the upper block is called the force of friction or

friction.

Types or friction:

1. Static

friction: It is experienced by a body, when at rest.

2. Dynamic

friction: It is friction experienced by a body when in motion.

a. Sliding

friction: It is friction experienced by a body when it slides over another

body.

b. Rolling

friction: It is friction experienced between the surfaces which the balls or

rollers interposed between them.

c. Pivot

friction: It is the friction experienced by a body due to motion of rotation.

Further

classified

1. Friction

between unlubricated surfaces

2. Friction

between lubricated surfaces. Laws of dry or solid friction:

Ø The force

of friction directly proportional to the normal load between the surfaces.

Ø The force

of friction is independent of the area of the contact surface for a given

normal load.

Ø The force

of friction depends upon material which the contact surfaces or made.

Ø The force

of friction is independent of the velocity of sliding of one body relative to

other body.

Coefficient

of friction (µ):

It is as

the ratio the limiting friction (F) to the normal reaction (RN) between the two

bodies.

µ= F/ RN

Angle of

friction:

It may be defined as the angle which the resultant

reaction R makes with normal reactions

tan ϕ= F/ RN

2 Friction drives:

3 Friction in screw threads:

·

Friction in screw and nut

·

Friction in screw jack

·

Problems in screw jack

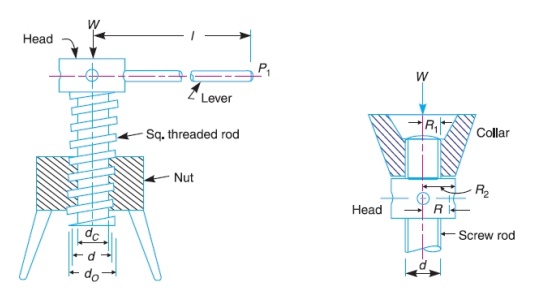

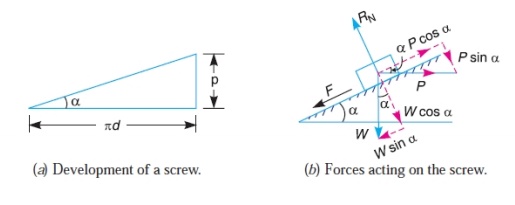

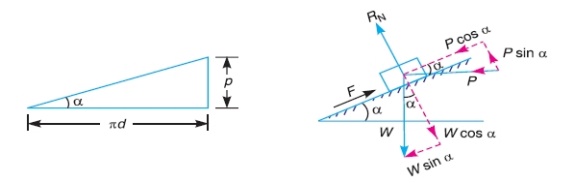

Screwjack:

The screw

jack is a device lifting loads. For lifting heavy loads by applying a

comparatively smaller effort at its handle. The principle on which a screw jack

works in a smaller to that of an inclined plane.

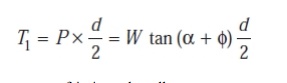

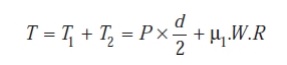

1. Torque required lifting the load by a screw jack

Let p=pitch of the screw

d =mean

diameter of the screw

α= helix

angle

P= effort

applied at the circumference of the screw to lift the load

W=load to

be lifted

µ=coefficient

of the friction

tan

α=p/Πd

Torque

required overcoming friction between the screw and nut

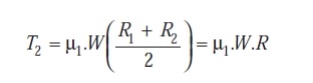

The

torque required to overcome friction at the collar

Total

Torque required overcoming friction

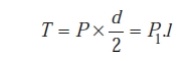

If an P1

is applied at the end of a lever of arm l, then the total torque required to

overcome friction must be equal to the torque applied at the end of the lever

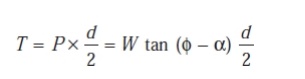

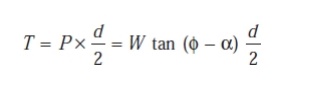

2. Torque required lower the load by a screw jack

Let p=pitch of the screw

d =mean

diameter of the screw

α= helix

angle

P= effort

applied at the circumference of the screw to lift the load

W=load to

be lifted

µ=coefficient

of the friction

tan

α=p/Πd

Torque

required overcoming friction between the screw and nut

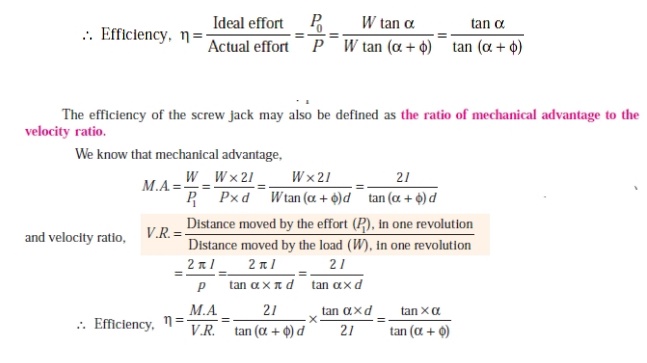

Efficiency

of the screw jack:

The

efficiency of the screw jack may b defined as the ratio between the ideal efforts

to actual effort.

Self

locking and over hauling of screws

Torque

required to lower the load

In the above expressions ,if ϕ< α ,then the torque required

to lower the load will be negative ,the load will start moving downward without

application of force, such a condition is known as overhauling of screw.

If ϕ> α ,then the torque required

to lower the load will be positive ,indicating that an efforts applied lower

the load , such a condition is known as self locking of screw

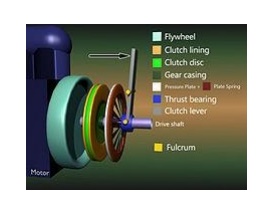

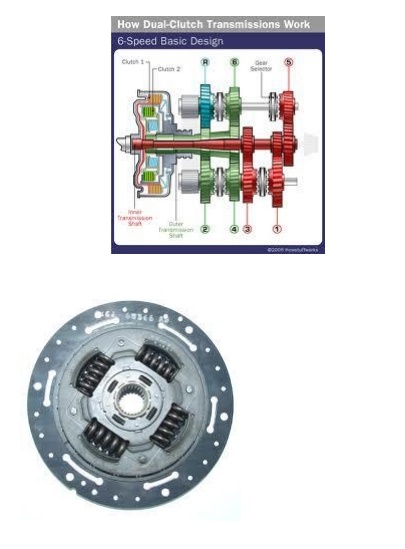

4 Clutch

For other uses, see Clutch (disambiguation).

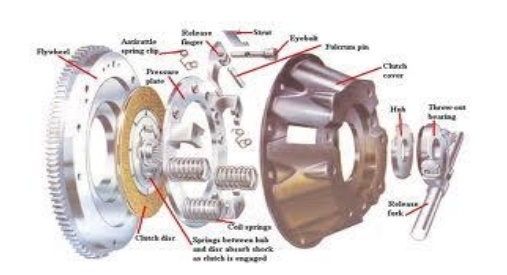

Clutch for a drive shaft: The clutch disc (center) spins with the flywheel (left).

To disengage, the lever is pulled

(black arrow), causing a white pressure plate (right) to disengage the green

clutch disc from turning the drive shaft, which turns within the thrust-bearing

ring of the lever. Never will all 3 rings connect, with no gaps.

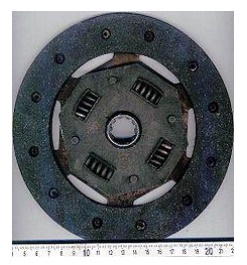

Rear side

of a Ford V6 engine, looking at the clutch housing on the flywheel

Single,

dry, clutch friction disc. The splined hub is

attached to the disc with springs to damp chatter.

A clutch is a mechanical device, by

convention understood to be rotating, which provides driving force to another

mechanism when required, typically by connecting the driven mechanism to the

driving mechanism. Clutches and brakes are similar; if the driven member of a

clutch is fixed to the mechanism frame, it serves as a brake.

Clutches are useful in devices that have two rotating shafts. In these devices, one shaft is typically attached to a motor or other power unit (the driving member), and the other shaft (the driven member) provides output power for work to be done. In a drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so that they can either be locked together and spin at the same speed (engaged), or be decoupled and spin at different speeds (disengaged).

Multiple plate clutch

This type

of clutch has several driving members interleaved with several driven members.

It is used in race cars including F1, Indy car, World rally and even most club

racing, motorcycles, automatic transmissions and in

some diesel locomotives with

mechanical transmissions. It is also used in some electronically controlled

all-wheel drive systems.

Vehicular

There are

different designs of vehicle clutch but most are based on one or more friction

discs pressed tightly together or against a flywheel using springs. The

friction material varies in composition depending on many considerations such

as whether the clutch is "dry" or "wet". Friction discs

once contained asbestos but this has been largely eliminated. Clutches found in

heavy duty applications such as trucks and competition cars use ceramic

clutches that have a greatly increased friction coefficient. However, these

have a "grabby" action generally considered unsuitable for passenger

cars. The spring pressure is released when the clutch pedal is depressed thus

either pushing or pulling the diaphragm of the pressure plate, depending on

type. However, raising the engine speed too high while engaging the clutch

causes excessive clutch plate wear. Engaging the clutch abruptly when the

engine is turning at high speed causes a harsh, jerky start. This kind of start

is necessary and desirable in drag racing and other competitions, where speed

is more important than comfort.

5.4.1 Friction clutches:

Single

plate clutches and Multi-plate clutche Uniform wear theory and Uniform pressure

theory Problems in clutches

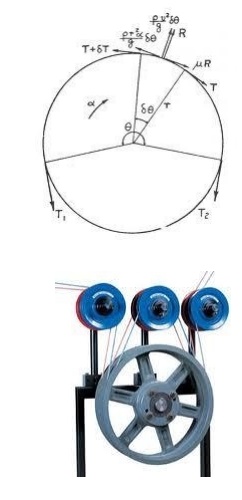

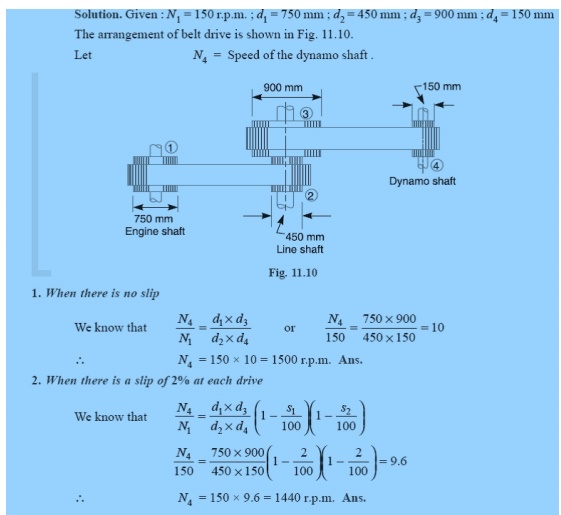

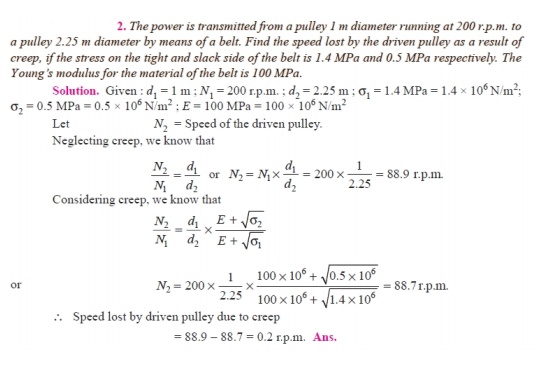

5 BELT

The belt or

ropes are used to transmit power from one shaft to another shaft by means of pulleys

which rotate at the same speed or at different speed.

Types of belt

drives.

1. Light

drives: belt speed upto10m/s

2. Medium

drives: speed 10m/s to22m/s

3. Heavy

drives :Speed ove r22m/s

1Types of belt

1.Flat

belt

2.V- belt

3.Circular

belt or rope

Type of

flat belt drives

Open belt

drive

Cross

belt drive

Quarter

turn belt drive

Belt

drive with idler pulley

Velocity

of belt drive

It is the

ratio between the velocies of the driver and follower or driven.

d1 = diameter

of the driver

d2 = diameter

of the follower

N1 = Speed

of the driver r.p.m

N2 = Speed

of the driven r.p.m

Let r1

and r1 = Radii

of the larger or smaller pulleys

x

=Distance between the centres of the two pulleys

L = Total length of the belt.

Length of

an open belt drive

Length of

the cross belt drive.

Power

transmitted by a belt

T1

and T2 = Tensions in the tight and slack side of

the belt respectively N

r1 and r1 = Radii

of the larger or smaller pulleys

v =Velocity of the belt m/s

Power = (T1-T2)v

W

Belt and rope drives:

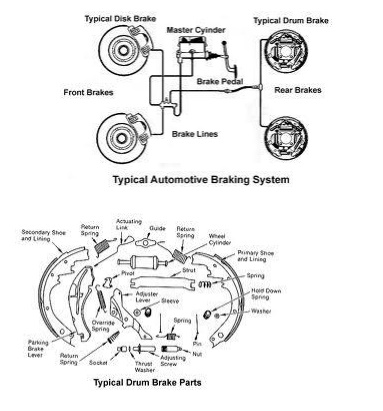

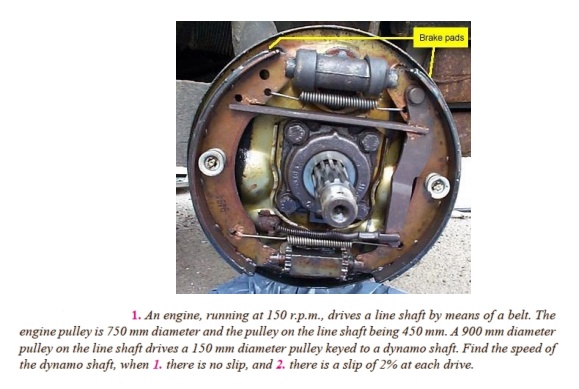

6 Friction aspects in Brakes:

BRAKES

Related Topics