Chapter: Mechanical : Unconventional machining process : Thermal Energy Based Processes

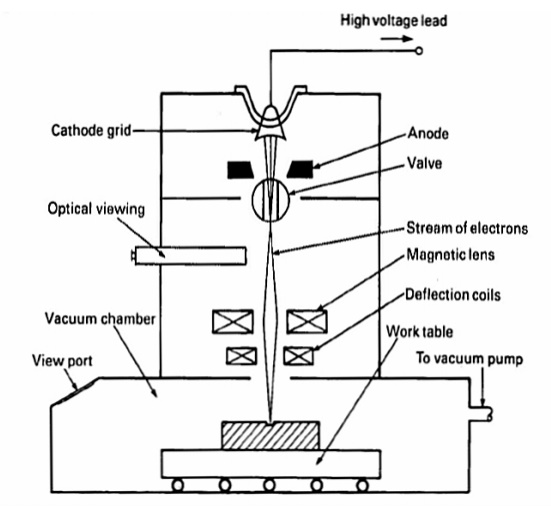

Electron Beam Machining (EBM)

ELECTRON BEAM MACHINING (EBM)

As has already been mentioned in EBM the gun is operated in pulse mode. This is achieved by appropriately biasing the biased grid located just after the cathode. Switching pulses are given to the bias grid so as to achieve pulse duration of as low as 50 μs to as long as 15 ms. Beam current is directly related to the number of electrons emitted by the cathode or available in the beam. Beam current once again can be as low as 200 μamp to 1 amp. Increasing the beam current directly increases the energy per pulse. Similarly increase in pulse duration also enhances energy per pulse. High-energy pulses (in excess of 100 J/pulse) can machine larger holes on thicker plates. The energy density and power density is governed by energy per pulse duration and spot size. Spot size, on the other hand is controlled by the degree of focusing achieved by the electromagnetic lenses. A higher energy density, i.e., for a lower spot size, the material removal would be faster though the size of the hole would be smaller. The plane of focusing would be on the surface of the work piece or just below the surface of the work piece.

1. Electrons generated in a vacuum chamber

2. Similar to cathode ray tube

3. Electron gun

4. Cathode - tungsten filament at 2500 – 3000 degC

5. Emission current – between 25 and 100mA (a measure of electron beam density)

MRR:

In the region where the beam of electrons meets the workpiece, their energy is converted Into heat

Workpiece surface is melted by a combination of electron pressure and surface tension Melted liquid is rapidly ejected and vaporized to effect material removal

Temperature of the workpiece specimen outside the region being machined is reduced by pulsing the electron beam (10 kHz or less)

Advantages of Ebm:

1. Large depth-to-width ratio of material penetrated by the beam with applications of very fine hole drilling becoming feasible

2. There are a minimum nu mber of pulses ne associated with an optimum accelerating Voltage. In practice the number of pulses to produce a given hole depth is usually found to decrease with increase in accelerating voltage.

Related Topics