Chapter: Mechanical : Unconventional machining process : Electrical Based Processes

Electrical Based Processes

ELECTRICAL

BASED PROCESSES

ELECTRICAL

BASED PROCESSES

•

Electrical

Discharge `Machining (EDM)

•

Wire

Cut Electrical Discharge Machining (WCEDM)

1.

Electrical Discharge `Machining (EDM)

Electrical

discharge machining (EDM) is one of the most widely used non-traditional

machining processes. The main attraction of EDM over traditional machining

processes such as metal cutting using different tools and grinding is that this

technique utilizes thermoelectric process to erode undesired materials from the

work piece by a series of discrete electrical sparks between the workpiece and

the electrode. A picture of EDM machine in operation

The traditional machining processes

rely on harder tool or abrasive material to remove the softer material whereas

non -traditional machining processes such as EDM uses electrical spark or

thermal energy to erode unwanted material in order to create desired shape. So,

the hardness of the material is no longer a dominating factor for EDM process.

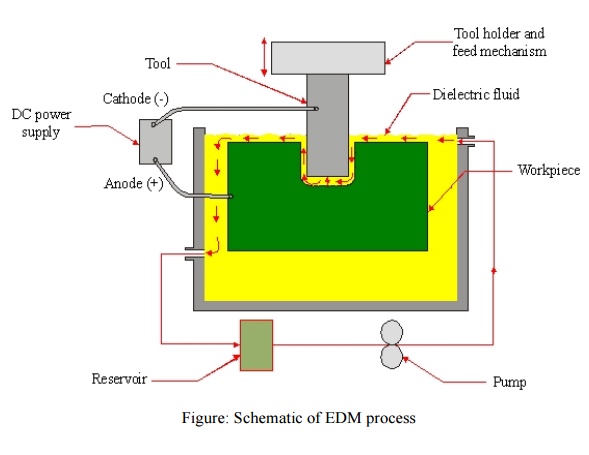

A schematic of an EDM process is shown in Figure 2, where the tool and the

workpiece are Immersed in a dielectric fluid.

Figure: Schematic of EDM process

EDM

removes material by discharging an electrical current, normally stored in a

capacitor bank, across a small gap between the tool (cathode) and the workpiece

(anode) typically in order

1. Application of EDM

The EDM process has the ability to

machine hard, difficult-to-machine materials. Parts with complex, precise and

irregular shapes for forging, press tools, extrusion dies, difficult internal

shapes for aerospace and medical applications can be made by EDM process. Some

of the shapes made by EDM process are shown in Figure.

Figure: Difficult internal parts

made by EDM process

2. Working principle of EDM

As

shown in Figure 1, at the beginning of EDM operation, a high voltage is applied

across the narrow gap between the electrode and the workpiece. This high

voltage induces an electric field in the insulating dielectric that is present

in narrow gap between electrode and workpiece. This cause conducting particles

suspended in the dielectric to concentrate at the points of strongest

electrical field. When the potential difference between the electrode and the

workpiece is sufficiently high, the dielectric breaks down and a transient

spark discharges through the dielectric fluid, removing small amount of

material from the workpiece surface.

![]()

The volume of the material removed

per spark discharge is typically in the range of 10-6 to 10-6 mm3.

The material removal rate, MRR, in

EDM is calculated by the following formula: MRR = 40 I / Tm 1.23 (cm3/min)

Where, I is the current amp, TM is

the melting temperature of workpiece in 0C

3. Advantages of EDM

The main advantages of DM are:

•

By

this process, materials of any hardness can be machined;

•

No

burrs are left in machined surface;

•

One

of the main advantages of this process is that thin and fragile/brittle

components

can be machined without distortion;

• Complex

internal shapes can be machined

3. Limitations of EDM

The main limitations of this process

are:

•

This

process can only be employed in electrically conductive materials;

•

Material

removal rate is low and the process overall is slow compared to conventional

machining processes;

•

Unwanted

erosion and over cutting of material can occur;

•

Rough

surface finish when at high rates of material removal.

4. Dielectric fluids

Dielectric fluids used in EDM

process are hydrocarbon oils, kerosene and deionised water. The functions of

the dielectric fluid are to:

•

Act

as an insulator between the tool and the workpiece.

•

Act

as coolant.

•

Act

as a flushing medium for the removal of the chips.

The electrodes for EDM process

usually are made of graphite, brass, copper and copper-tungsten alloys.

5. Design considerations for EDM process are as follows:

•

Deep

slots and narrow openings should be avoided.

•

The

surface smoothness value should not be specified too fine.

•

Rough

cut should be done by other machining process. Only finishing operation should

be done in this process as MRR for this process is low.

2

WIRE CUT ELECTRICAL DISCHARGE MACHINING (WCEDM)

EDM,

primarily, exists commercially in the form of die-sinking machines and

wire-process, a slowly moving wire travels along a prescribed path and removes

material from the workpiece. Wire EDM uses electro-thermal mechanisms to cut

electrically conductive materials. The material is removed by a series of

discrete discharges between the wire electrode and the workpiece in the

presence of dielectric fluid, which creates a path for each discharge as the

fluid becomes ionized in the gap. The area where discharge takes place is

heated to extremely high temperature, so that the surface is melted and

removed. The removed particles are flushed away by the flowing dielectric

fluids.

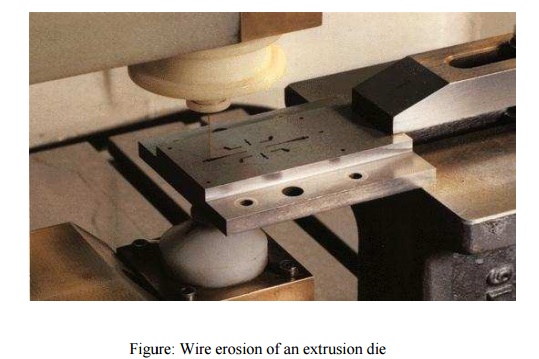

The wire EDM process can cut

intricate components for the electric and aerospace industries. This

non-traditional machining process is widely used to pattern tool steel for die

manufacturing cutting machines (Wire EDM). The concept of wire EDM is shown in

Figure . In this

Figure: Wire erosion of an extrusion

die

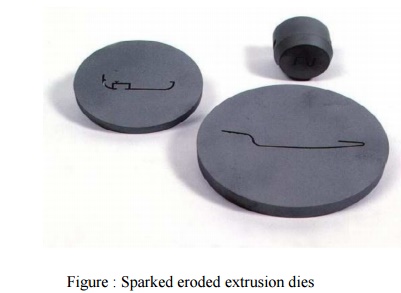

The wires for wire ED M is made of

brass, copper, tungsten, molybdenum. Zinc or brass coated wires are also used

extensively in this process. The wire used in this process should posse’s high

tensile strength and good e lectrical conductivity. Wire EDM can also employ to

cut cylindrical objects with high precision. Th e sparked eroded extrusion dies

are presented in Figure.

Figure : Sparked eroded extrusion

dies

This

process is usually used in conjunction with CNC and will only work when a part

is to be cut completely through. T he melting temperature of the parts to be

machined is an important parameter for this process rather than strength or

hardness. The surface quality and MRR of the machined surface by wire EDM will

depend on different machining parameters such as applied peak current, an d

wire materials.

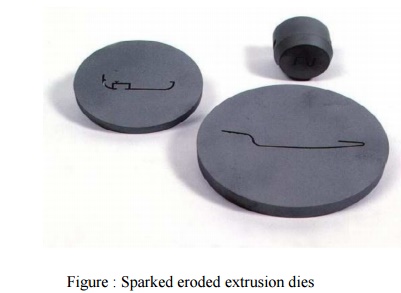

The wires for wire EDM is made of

brass, copper, tungsten, molybdenu m. Zinc or brass coated wires are also used

extensively in this process. The wire used in this process should posses’ high

tensile strength and good electrical con ductivity. Wire EDM can also employ to

cut cylindrical objects with high precision. The sparked eroded extrusion dies

are presented in Figure 5.

Figure: Sparked eroded extrusion

dies

This process is usually used in

conjunction with CNC and will only work when a part is to be cut completely

through. T he melting temperature of the parts to be machined is an important

parameter for this process rather than strength or hardness. The surface

quality and MRR of the machined surface by wire EDM will depend on different

machining parameters such as applied peak current, an d wire materials.

Related Topics