Chapter: Mechanical : Unconventional machining process : Chemical and Electro Chemical Energy Based Processes

Chemical and Electro Chemical Energy Based Processes

CHEMICAL

AND ELECTRO CHEMICAL ENERGY BASED PROCESSES

· Chemical Machining

· Chemical milling

· Electrochemical Machining

· Electrochemical Honing

· Electrochemical Grinding

1. CHEMICAL MACHINING

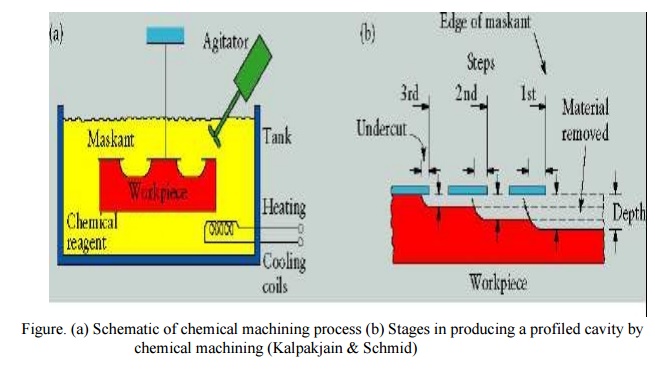

Chemical

machining (CM) is the controlled dissolution of work piece material (etching)

by means of a strong chemical reagent (etchant). In CM material is removed from

selected areas of work piece by immersing it in a chemical reagents or

etchants; such as acids and alkaline solutions. Material is removed by

microscopic electrochemical cell action, as occurs in corrosion or chemical

dissolution of a metal. This controlled chemical dissolution will

simultaneously etch all exposed surfaces even though the penetration rates of

the material removal may be only 0.0025–0.1 mm/min. The basic process takes many

forms: chemical milling of pockets, contours, overall metal removal, chemical

blanking for etching through thin sheets; photochemical machining (pcm) for

etching by using of photosensitive resists in microelectronics; chemical or

electrochemical polishing where weak chemical reagents are used (sometimes with

remote electric assist) for polishing or deburring and chemical jet machining

where a single chemically active jet is used. A schematic of chemical machining

process is shown in Figure.

Figure. (a) Schematic of chemical

machining process (b) Stages in producing a profiled cavity by chemical

machining (Kalpakjain & Schmid)

2. Chemical milling

In chemical milling, shallow

cavities are produced on plates, sheets, forgings and extrusions. The two key

materials used in chemical milling process are etchant and maskant. Etchants

are acid or alkaline solutions maintained within controlled ranges of chemical

composition and temperature. Maskants are specially designed elastomeric products

that are hand strippable and chemically resistant to the harsh etchants.

Steps in chemical milling

•

Residual

stress relieving: If the part to be machined has residual stresses from the

previous processing, these stresses first should be relieved in order to

prevent warping after chemical milling.

•

Preparing:

The surfaces are degreased and cleaned thoroughly to ensure both good adhesion

of the masking material and the uniform material removal.

•

Masking:

Masking material is applied (coating or protecting areas not to be etched).

•

Etching:

The exposed surfaces are machined chemically with etchants.

•

Demasking:

After machining, the parts should be washed thoroughly to prevent further

reactions with or exposure to any etchant residues. Then the rest of the

masking material is removed and the part is cleaned and inspected.

Applications:

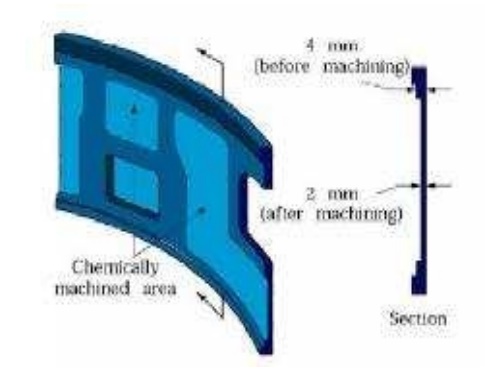

Chemical milling is used in the

aerospace industry to remove shallow layers of material from large aircraft

components missile skin panels (Figure 7), extruded parts for airframes.

Figure: Missile skin-panel section

contoured by chemical milling to improve the stiffness- to- weight ratio of the

part (Kalpakjain & Schmid)

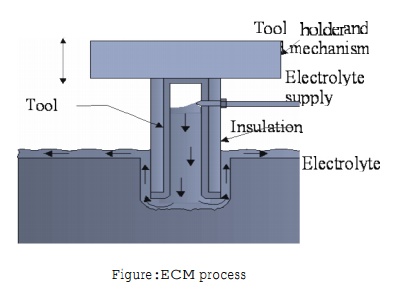

3. Electrochemical Machining (ECM)

Introduction

Electrochemical

machin ing (ECM) is a metal -removal process base d on the principle of reverse

electroplating. In this p rocess, particles travel from the anodic material

(workpiece) toward the cathodic material (machining tool). A current of

electrolyte fluid carries away the depleted material before it has a chance to

reach the machining tool. The cavity produced is the female mating image of the

tool shape.

Figure:ECM process

Similar to EDM, the work piece

hardness is not a factor, making ECM su itable for machining difficult-to

–machine materials. Difficult shapes can be made by this process o n materials

regardless of their hardness. A schematic r epresentation of ECM process is

shown in Figure. The ECM tool is positioned very close to the work piece and a

low voltage, high amperage DC c urrent is passed between the work piece and

electrode. Some of the shapes made by ECM proc ess is shown in Figure.

Figure: Parts made by ECM

Advantages of ECM

• The components are not subject to

either thermal or mechanical stress.

• No tool wears during ECM process.

• Fragile parts can be machined easily

as there is no stress involved.

•

ECM

deburring can debur difficult to access areas of parts.

•

High

surface finish (up to 25 µm in) can be achieved by ECM process.

• Complex geometrical shapes in

high-strength materials particularly in the aerospace industry for the mass

production of turbine blades, jet-engine parts and nozzles can be machined

repeatedly and accurately.

•

Deep

holes can be made by this process.

Limitations of ECM

• ECM is not suitable to produce sharp

square corners or flat bottoms because of the tendency for the electrolyte to

erode away sharp profiles.

• ECM can be applied to most metals

but, due to the high equipment costs, is usually used primarily for highly

specialized applications.

Material removal rate, MRR, in ECM

MRR

= C .I. h (cm3/min)

C: specific (material) removal rate

(e.g., 0.2052 cm3/amp-min for nickel); I: current (amp);

h: current efficiency (90–100%).

The rates at which metal can

electrochemically remove are in proportion to the current passed through the

electrolyte and the elapsed time for that operation. Many factors other than Current

influence the rate of machining. These involve electrolyte type, rate of electrolyte

flow, and some other process conditions.

4. ELECTROCHEMICAL HONING

Electrochemical

honing is one of the non-equilibrium gap processes in ECM and is a new

technique, which in spite of being used in some industrial plants especially to

smooth surfaces, is still not fully described due to the variety of the factors

affecting the process. More information about the process is required

especially the effects of the working parameters on the produced surface

roughness. A special honing tool was designed by using different tool tip

shapes (rectangular, circular, triangle & inclined) to study the ability

for improving the surface roughness. This work presents a study for the factors

affecting the electrochemical honing process especially the machining time,

work piece material, initial working gap, tool rotational speed, tool tip shape

and the inclined tool tip angle. The results are finally furnished with the aim

to generalize a useful guideline for the user to enable proper selection of

conditions for obtaining good surface quality.

5. ELECTROCHEMICAL GRINDING (ECG)

Electrochemical

Grinding, or ECG, is a variation of ECM (Electrochemical Machining) that

combines electrolytic activity with the physical removal of material by means

of charged grinding wheels. Electrochemical Grinding (ECG) can produce burr

free and stress free parts without heat or other metallurgical damage caused by

mechanical grinding, eliminating the need for secondary machining operations.

Like ECM, Electrochemical Grinding (ECG) generates little or no heat that can

distort delicate components.

Electrochemical

Grinding (ECG) can process any conductive material that is electrochemically

reactive. The most common reason customers choose Electrochemical Grinding

(ECG) is for the burr free quality of the cut. If a part is difficult or costly

to deburr, then Electrochemical GRINDING (ECG) is the best option. Materials

that are difficult to machine by conventional methods, that work harden easily

or are subject to heat damage are also good candidates for the stress free and

no heat characteristics of Electrochemical Grinding (ECG). The stress free

cutting capability of the process also makes it ideal for thin wall and

delicate parts.

The

real value of Electrochemical Grinding (ECG) is in metalworking applications

that are too difficult or time-consuming for traditional mechanical methods

(milling, turning, grinding, deburring etc.). It is also effective when

compared to non-traditional machining processes such as wire and sinker EDM.

Electrochemical Grinding (ECG) is almost always more cost effective than EDM.

Electrochemical

Grinding (ECG) differ from conventional grinding Conventional surface grinding

typically uses shallow reciprocating cuts that sweep across the work surface to

create a flat plane or groove. Another conventional surface grinding process,

creep feed grinding, typically uses slower feeds than conventional surface

grinding and removes material in deep cuts. Because of the abrasive nature of

these processes, the equipment used must be rigid and this is especially true

of creep feed grinding.

Quality

Electrochemical Grinding (ECG) machines must also be rigid for close tolerance

results but since very little of the material removed is done so abrasively the

machines do not have to be as massive as their conventional counterparts. To a

user familiar with creep feed grinding Electrochemical Grinding (ECG) will

appear to be very similar, that is, relatively slow feeds (as compared to

conventional surface grinding) and deep cuts as opposed to shallow

reciprocating cuts. Electrochemical Grinding (ECG) is a combination of

electrochemical (Anodic) dissolution of a material, according to Faraday’s Law,

and light abrasive action. The metal is decomposed to some degree by the DC

current flow between the conductive grinding wheel (Cathode) and the work piece

(Anode) in the presence of an electrolyte solution.

Unlike

conventional grinding techniques, Electrochemical Grinding (ECG) offers the

ability to machine difficult materials independent of their hardness or

strength. Electrochemical Grinding (ECG) does not rely solely on an abrasive

process; the results are precise burr free and stress free cuts with no heat

and mechanical distortions.

Electrochemical

Grinding (ECG) compare to EDM, laser, water-jet and other non-traditional

technologies EDM and laser both cut metal by vaporizing the material at very

high emperatures.

This

results in a re-cast layer and a heat affected zone on the material surface.

Electrochemical Grinding (ECG) is a no heat process that never causes

metallurgical damage. Electrochemical Grinding (ECG) is usually much faster

than EDM but typically is less accurate. Laser cutting can be very fast and

accurate but it is normally limited to thin materials. Water-jet cutting can be

quite fast and usually leaves no metallurgical damage but the consumable costs

can be very high and the cuts are limited to jigsaw type cuts much like Wire

EDM. In most cases, Electrochemical Grinding (ECG) is a more accurate process

than water-jet. Another difference between water jet and laser machining

compared to electrochemical grinding (ecg) is laser and water jet can both

process materials that are not conductive. edm and electrochemical grinding

(ecg) processes can only work on materials that are conductive.

Tolerances

can be achieved with electrochemical grinding (ecg) the tolerances that can be

achieved using electrochemical grinding (ecg) depend greatly on the material

being cut, the size and depth of cut and ecg parameters being used. on small

cuts, tolerances of .0002” (.005mm) can be achieved with careful control of the

grinding parameters.

1 Surface Finishes Can Be Achieved With Electrochemical

Grinding (Ecg)

The

Electrochemical Grinding (ECG) process does not leave the typical shiny finish

of abrasive grinding. This is because there is no smearing of the metal as in

conventional grinding. A 16 micro inch finish or better can be achieved but it

will have a matte (dull) rather than a polished look.

2. Materials Can Be Cut With Electrochemical Grinding (ECG)

Almost

any conductive metal can cut with Electrochemical Grinding (ECG). Steel,

Aluminum, Copper, Stainless Steels, Inconel and Hastelloy cut very freely with

Electrochemical Grinding (ECG). Nickel/Titanium, Cobalt alloys, Amorphous

metals, Berilium, Berilium Copper, Iridium Neodymium Iron Boron, Titanium,

Nickel/Titanium, Nitinol, Powdered Metals, Rene 41, Rhenium, Rhodium,

Stelllite, Vitalium, Zirconium and Tungsten can also be cut effectively.

3. Advantages of Electrochemical Grinding (ECG)

•

Improved

wheel life

•

Burr

free

•

No

work hardening

•

Stress

free

•

Better

finis

•

No

cracking

•

Less

frequent wheel dressing

•

No

metallurgical damage from heat

•

Faster

for tough materials

•

No

wheel loading or glazing

•

More

precise tolerances

Related Topics