Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Automotion and Control Technologies

Automotion and Control Technologies

Automotion

and Control Technologies

CONTENTS

Basic Elements

of an Automated System

Power to

Accomplish the Automated Process

Program

of Instructions

Control

System

Advanced

Automation Functions

Safety Monitoring

Maintenance

Rapair Diagnostics

Error

Detection and Recovery

Levels of

Automation

Automation is the

technology by which a

process or procedure is accomplished without

human assistance. It is implemented using a program of instructions combined with a controt system that executes the instructions, To automate a

process.power is required, both to drive

the process itself and to operate the program and control system. Although

automation can be applied in a wide variety of areas, it is most closely associated

with the manufacturing industries. It was in the context of manufacturing that

the term was originally coined hy an engineering manager at Ford Motor Company

in 1946 to describe the varicty of automatic transfer devices and feed

mechanisms that had been installed in Ford's production plants (Historical Note

3.1), It is ironic that nearly all modern applications of automation are

controlled by computer technologies that were not available in 1946.

In this

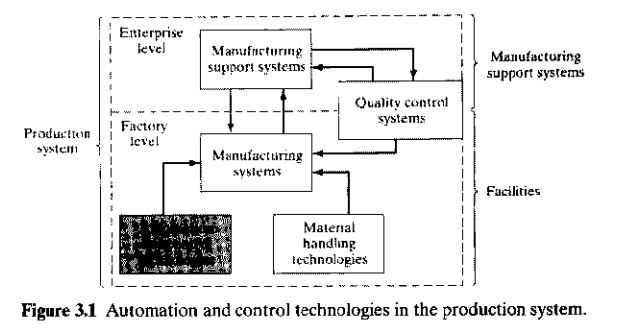

pat of the book, we examine technologies that have been developed to uutamale manufacturing operations. The

position of automation and control technologies in the larger production system

is shown in Figure 3.1. In the present chapter, we provide an

Figure 3.1 Automation and control technologies in the production system.

overview

of automation: What are the elements of an automated system? What are some of

the advanced features beyond the basic elements? And what are the levels in an

enterprise where automation can be applied? In the following two chapters, we

discuss industrial control systems and the hardware components of these

systems. These two chapters serve as a foundation for the remaining chapters in

our coverage of automation and control technologies. These technologies are:

(1) numerical control (Chapter 6), (2) industrial robotics (Chapter 7), and (3)

programmable logic controllers (Chapter 8).

Historical Note 3.1 History of

automation 1

The history of automation can be traced to the

development of basic mechanical devlcea such as the wheel (circa 3200 B.C.),

lever, winch (circa 600 B.C.), cam (circa A.D. 1000), screw (A.D. 1405). and

gear in ancient and medieval times. These basic devices were refined and used

to construct the mechanisms in waterwheels, windmills (circa A.D. 650), and

steam engines (A.D. 1765).These machines generated the power to operate other

machinery of various kinds, such as flour mills (circa 85 B.c.), weaving

machines (flying shuttle, 1733),machine tools (boring mill, 1775),steamboats (1787),and

railroad locomotives (1803). Power,

and the capacity to generate it and transmit it to operate a process, is one of

the three basic elements of an automated system.

After his first steam engine in 1765,James Watt and

his partner, Matthew Boulton,made several improvements in the design. One of

the improvements was the flyingbali governor (around 1785),which provided

feedback to control the throttle of the engine. The govemorconsisted of a ball

on the end of a hinged lever attached to the rotating shaft. The lever was

connectedtothethrottievalve.Astbespeedoftherotatingshaftincreased,the ball was

forced to move outward by centrifugal force; this in tum caused the lever to

reduce the valve opening and slow the motor speed. As rotational speed decreased,

the ball and lever relaxed, thus allowing the valve to open. The flyingball

governor was one of the first examples in englneering of feedback control, an

important type of contro/systemthe

second basic element of an automated system.

Related Topics