Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Production Planning and Control Systems

Aggregate Production Planning and the Master Production Schedule

AGGREGATE

PRODUCTION PLANNING AND

THE MASTER PRODUCTION SCHEDULE

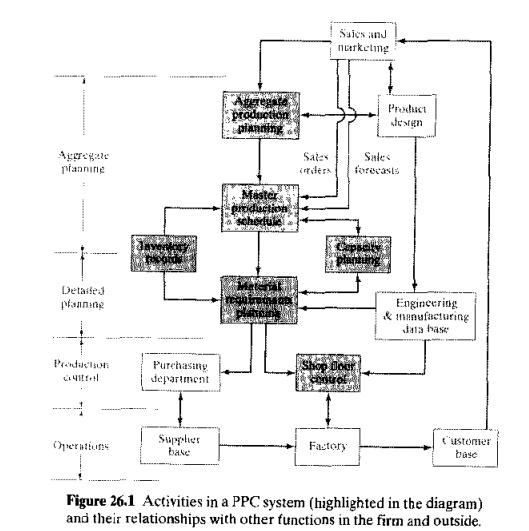

Aggregate planning is a high-level corporate planning activity. The aggregate production pian indicates production output levels for the major product lines of the company. The aggregate plan must be coordinated with the plans of the sales and marketing departments. Because the aggregate production plan includes products that are currently in production, it must also consider the present and future inventory levels of those products and their component parts. Because new products currently being developed will also be included in the aggregate plan. the marketing plans and promotions for current products and new products must be reconciled against the total capacity resources available to the company.

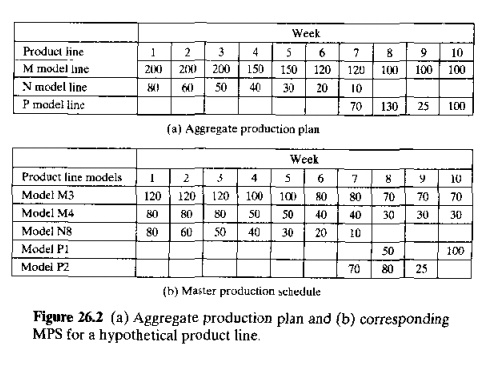

The

production quantities of the major product lines listed in the aggregate plan

must he converted into a very specific schedule of individual products, known

as the master production schedule (MPS).lt

is a list or the products to be manufactured, when they should be completed and delivered, and in what

quantities. A hypothetical MPS for a narrow product set is presented in Figure

26.2(0), showing how it is derived from the conesponding aggregate plan in

Figure 26.2(a). The master schedule must be based on an accurate estimate of

demand and a realistic assessment of the company's production capacity.

Products included in the MPS divide into three

categories: (1) firm customer orders, (2) forecasted demand, and (3) spare

parts. Proportions in each category vary for different companies, and in some

cases one or more categories are omitted. Companies producing assembled

products will generally have to handle all three types. In the case of customer

orders for specific products, the company is usually obligated to delivery the

item by a particular date that has been promised by the sales department. In

the second category. production output quantities are based on statistical forecasting techniques

applied to previous demand patterns, estimates by the sales staff. and other

sources. For many companies, forecasted demand constitutes the largest portion

of the master schedule. The third category consists of repair parts that will

either be stocked in the company's service department or sent directly to the

customer. Some companies exclude this third category from the master schedule

since it does not represent end products.

The MPS

is generally considered to be a medium-range plan since it must take into

account The lead times to order raw materials and components, produce parts in

the factory, and then assemble the end products. Depending on the product. the

lead times can

range

from several weeks 10 many months; in some cases. more than a year. The MPS is usually

considered to he fixed in the near term. This means that changes arc not

allowed within about a 6 week honzon because of the difficulty in adjusting

production schedules within such a short period. However. schedule adjustments

are allowed beyond 6 weeks to cope with changing demand patterns or the

introduction of new products.Accordingly, we should note that the aggregate

production plan is not the only input to the master schedule. Other inputs that

may came the master schedule to depart from the aggregate plan include new

customer orders and changes in sales forecast over the near term.

Related Topics