Textiles and Dress Designing - Methods of Printing | 12th Textiles and Dress Designing : Chapter 3 : Printing

Chapter: 12th Textiles and Dress Designing : Chapter 3 : Printing

Methods of Printing

Methods of Printing

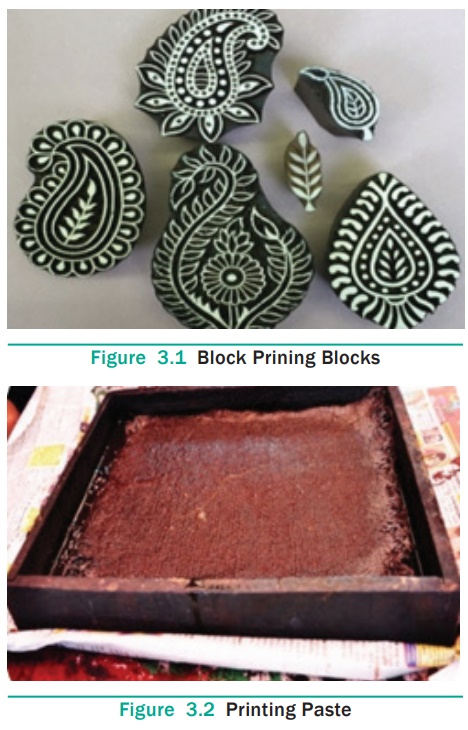

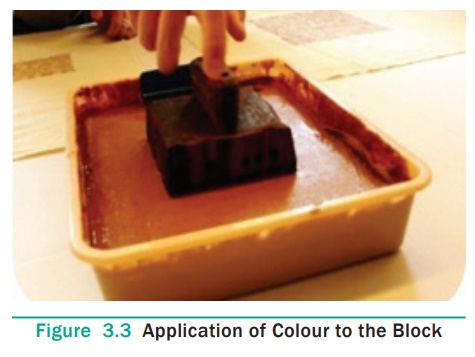

1. Block Printing

Block printing is the ancient method of printing designs on the

textile material by hand. It is the simplest of the printing methods. In this

method, the desired design is carved on a wooden or metal block. The fabric is

pinned on a table which is firm, strong and withstands the pressure of

printing. The top is made of metal with a resilient surface made of artificial

leather. The wooden block is stamped in the print paste or applied on the

surface of the block. The block is stamped firmly on the selected part of the

fabric. This process is repeated to print the required length of fabric.

Multicoloured designs require separate blocks for each colour. Block printing

is done mainly in decorative pieces or in expensive linens for upholstery

purposes.

Advantages

·

Simplest method of printing

·

Handmade art

·

No special printing equipment required

Disadvantages

·

Tedious and time consuming process

·

Expensive

·

Irregular colour shade

·

Overall production is low

·

Carving of blocks is difficult and laborious.

2. Roller Printing

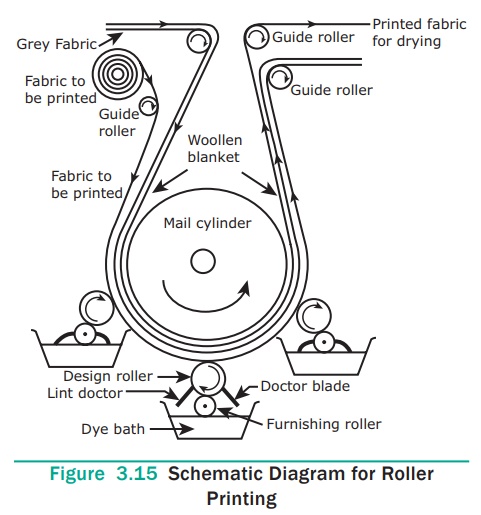

It is a machine printing method, in which designs are printed on

textile fabric by engraved rollers. This method of printing produces over 4000

yards of printed fabric per hour. The cylinder is made up of cast iron which

acts as a printing table. The cylinder is covered with many layers of special

fabric which has linen in warp and wool in weft for providing resiliency. It is

covered with a layer of woollen blanket which provides the perfect surface for

printing. The woollen blanket is covered with unbleached cotton cloth which

will absorb excess dye. The last layer is the fabric which is to be printed.

The design is transferred onto the cloth by engraved copper

rollers. The design roller is arranged in such a way that the paste is applied

on the roller and then transferred to the cloth. Number of engraved rollers

rotate in contact with larger cylinder in rotation. The cloth is printed at the

rate of 1000 to 4000 yards per hour. There are series of rollers each

imprinting a different colour on the fabric. The sizes of the engraved

cylinders depend on the pattern to be printed. There are different ways of

engraving the roller such as hand engraving, machine or mill engraving and

photographic engraving. The design roller rotates against the cloth and the

design is imprinted. The fabric moves on to the second roller where the second

colour is printed. The doctor blade placed in contact with design roller

scrapes the excess dye from the surface of the design roller. The printed cloth

is dried and then steamed to set the dye.

Advantages

·

Superior to other methods for the production of fine and precise

designs

·

Production is faster and accurate

·

All colours required to print can be achieved in one process

itself

·

Versatile in colours, pattern and scale

Disadvantages

·

Required skilled labour

·

Laborious process

·

Production cost is more for printing in small quantities

·

Creation of engraved rollers is expensive

·

Time consuming process

·

If rollers are not aligned properly, it results in one or more

colours falling out of position

3. Stencil Printing

In stencil printing, the design is first traced on the cardboard,

wood, metal or plastic sheets with marker pens or pencils. Using scissors,

knife or sharp blade the design is cut out. The uncut portion represents the

part that is to be left uncoloured. When cutting the stencil care must be taken

that small patterns must be cut through first. If large patterns are cut over

or keeping small pattern inside then the smaller designs would be cut away with

it. The stencil is placed on the fabric to be printed and the printing paste is

applied with stencil brush through its interstices. When printing is repeated,

care must be taken that the stencil on face side does not take up dye. Other

colours can be applied on the design when the first colour dries. This method

is suitable for both fine delicate design and large space design.

Advantages

·

Low budget investment

·

Exclusive designs and intricacy

Disadvantage

·

Unevenness on printing table leads to uneven printing

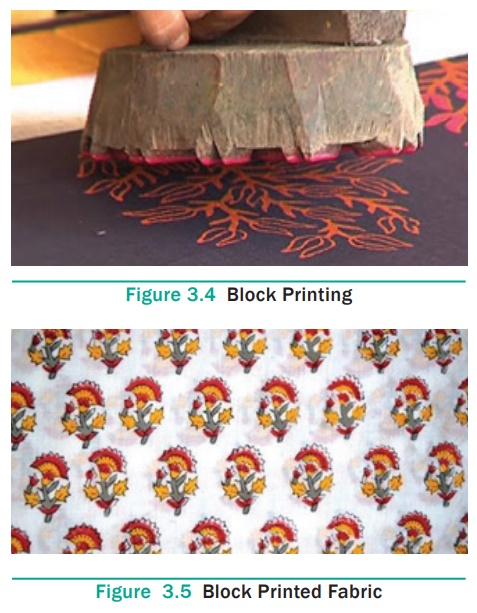

4. Screen Printing

In this printing method, fabric is spread on large table and

design screen is placed on the fabric. The screen consists of wooden frame

covered with nylon or silk cloth and the technique is called as silk screen

printing. Lacquer is applied on the screen to make the areas except design opaque

so that printing paste is transferred through the design only. Based on the

number of colours, many numbers of screens are prepared to complete the design.

The printed portion should be allowed to dry before placing the second screen.

When screens are placed properly, they will produce a complete design.

Advantages

·

Whole width of fabric is printed at once and so the process is

faster than block printing

·

Screens can be preserved for future use

Disadvantages

·

Preparation of screen is a time consuming process

·

Preservation of screen needs extra care

·

A small damage in the screen will spoil the entire printing

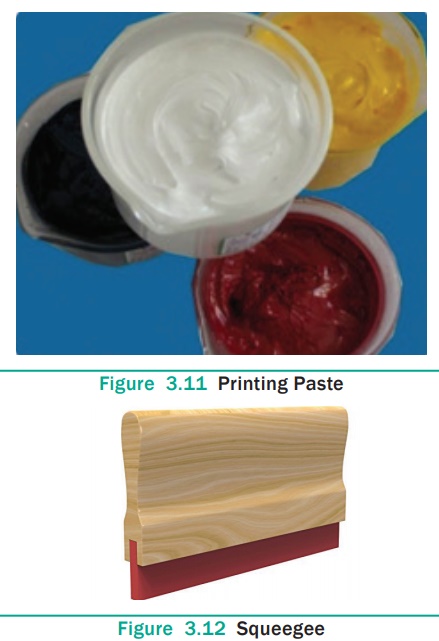

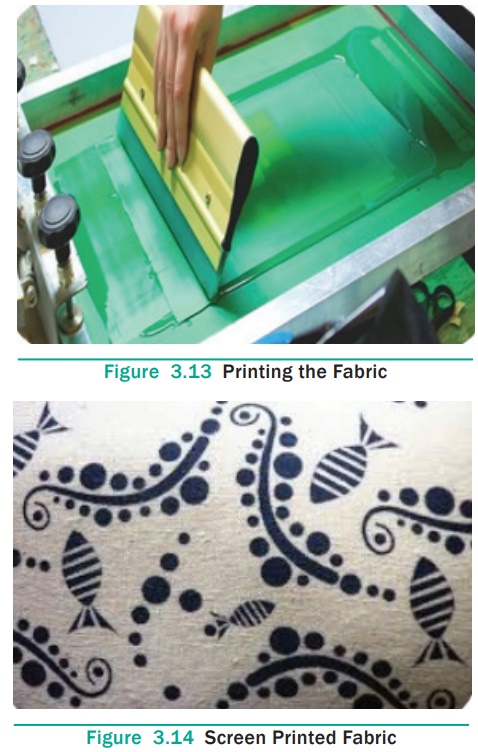

The design is created by painting or making non-design portions of

the screen opaque, thus preventing the print paste from passing through. The

areas where the print paste passes through will create a printed pattern. The

screen is placed in contact with the fabric to be printed and the print paste

is forced through the screen by a squeegee. The squeegee is used to spread the

dye evenly through the screen. It is moved across the screen, forcing the print

paste through the mesh openings. It helps in making a clean image on the

printed surface. A screen is prepared for each colour of the design. There are

two types of screen printing namely Flat screen printing and Rotary screen

printing.

Flat Screen Printing or Hand Screen Printing

It is done by hand. The design is copied onto a series of very

fine, flat screens, one for each colour to be printed. Lacquer or other

impermeable substance is applied to all parts of the screen that are not part

of its design. Each screen is fitted onto a wooden or metal frame. The fabric

to be printed is spread onto a long table. A screen is set over the fabric and

the printing paste is poured on the screen and forced through its unblocked

areas onto the fabric with a squeegee. The screen is then moved to the next

section of the fabric and the operation is repeated until the entire fabric is

printed. This process is repeated for each colour of the design. Hand screen

printing is time-consuming and limited to short length of fabrics.

Automatic Flat Screen Printing

In this method, the process is automated and therefore faster.

Here the fabric moves on a wide rubberized belt. The screens are placed above

the belt. As the fabric moves, the screens are automatically lowered to the

cloth and the appropriate colour is applied with automatically regulated

squeegees. The cloth is dried in an oven.

Advantages

·

Prints upto twenty colours in one run

·

High production rate

·

Produce brighter and cleaner shades

·

Produces designs consisting of squares, circles and ovals

Disadvantage

·

High cost

Rotary Screen Printing

This method of printing is done using machine. The fabric to be

printed is moved on a wide rubber belt under the rotary screen cylinders. It is

the fastest method of screen printing, with a production of more than 3500

yards per hour. A squeegee in each rotary screen forces the paste through the

screen onto the fabric. The cloth is then passed into a drying oven to set the

colour and washed.

Advantages

·

Faster method of printing

·

Rotary metal screens are light weight in contrast to the heavy

copper rollers and hence they cost less.

·

Operates continuously

·

Production output is higher

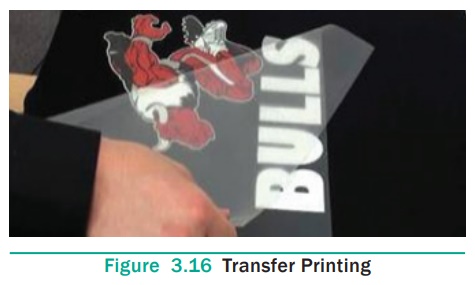

5. Transfer Printing

Transfer printing means shifting of a design from one surface to

another. In this method, designs made of pigments in paraffin or thermoplastic

base can be transferred by heat and pressure to the fabric surface. The fabrics

printed by this method become stiff and they are not fast to washing and light.

A more effective and easier method of transferring the design intact from paper

to fabric is by vaporizing the pigments in the design. Vaporizing can be done by

dry heat transfer and wet heat transfer.

Disperse dyes are the only dyes which can be sublimated and used

for heat transfer printing. Hence transfer printing is suitable for fabrics

which have affinity to disperse dyes. Polyester, nylon and acrylics can be

printed by this method. The fabric to be printed is passed through a heat

transfer printing machine which brings paper and fabric together and passes

them through the machine at about 204°C. Under high temperature, the dye on the

printed paper sublimates and is transferred onto the fabric.

Advantages

·

Production cost is low because there is no requirement of post

printing treatments

·

There is no wastage of pigment as the design made on paper is

transferred to fabric

·

Prints with excellent line details, intricacy and shading can be

done

·

Design can be made with many colours

·

Rich and brilliant shades can be generated on woven and knitted

fabrics

·

Process is simple and does not require skilled labour

·

High quality prints

·

Less time

·

Environment friendly process

·

Economical for short runs

Disadvantages

·

Selection of dyes is limited

·

Poor colourfastness

·

Not suitable for all types of fabrics

6. Batik Printing

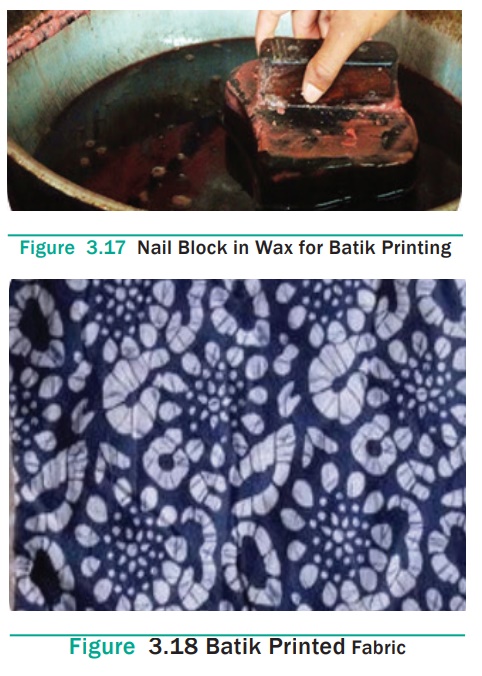

Batik printing is a hand printing method. This is a resist style

of printing. In this method, designs are made using wax and the fabric is

immersed in the dye bath to colour the unwaxed portions. The wax is applied

using various tools such as brushes, tjap and tjanting.

Tjanting is a spouted tool used to draw designs on the fabric with

melted wax. Tjap is a pattern made of fine copper strips. The tjap is pressed

on liquid wax and applied to the fabric. Wax is applied on both sides of the

fabrics. After application of wax, the fabric is dyed to obtain desired colour.

Only the portions not covered by the wax will absorb the dye. After the dye has

been fixed, the fabric is dried, then boiled and rinsed to remove the wax. It

is a slow process.

Advantage

·

Gives an artistic effect to the fabric

Disadvantages

·

Very laborious and time consuming process

·

Dye has to be applied at a temperature lower than the melting

point of wax

7. Photo Printing

In this method, the fabric is coated with a chemical that is

sensitive to light and photographs are printed on the fabric. The results are

similar to the photograph printed on the paper. This is a direct style of

printing.

Related Topics