Chapter:

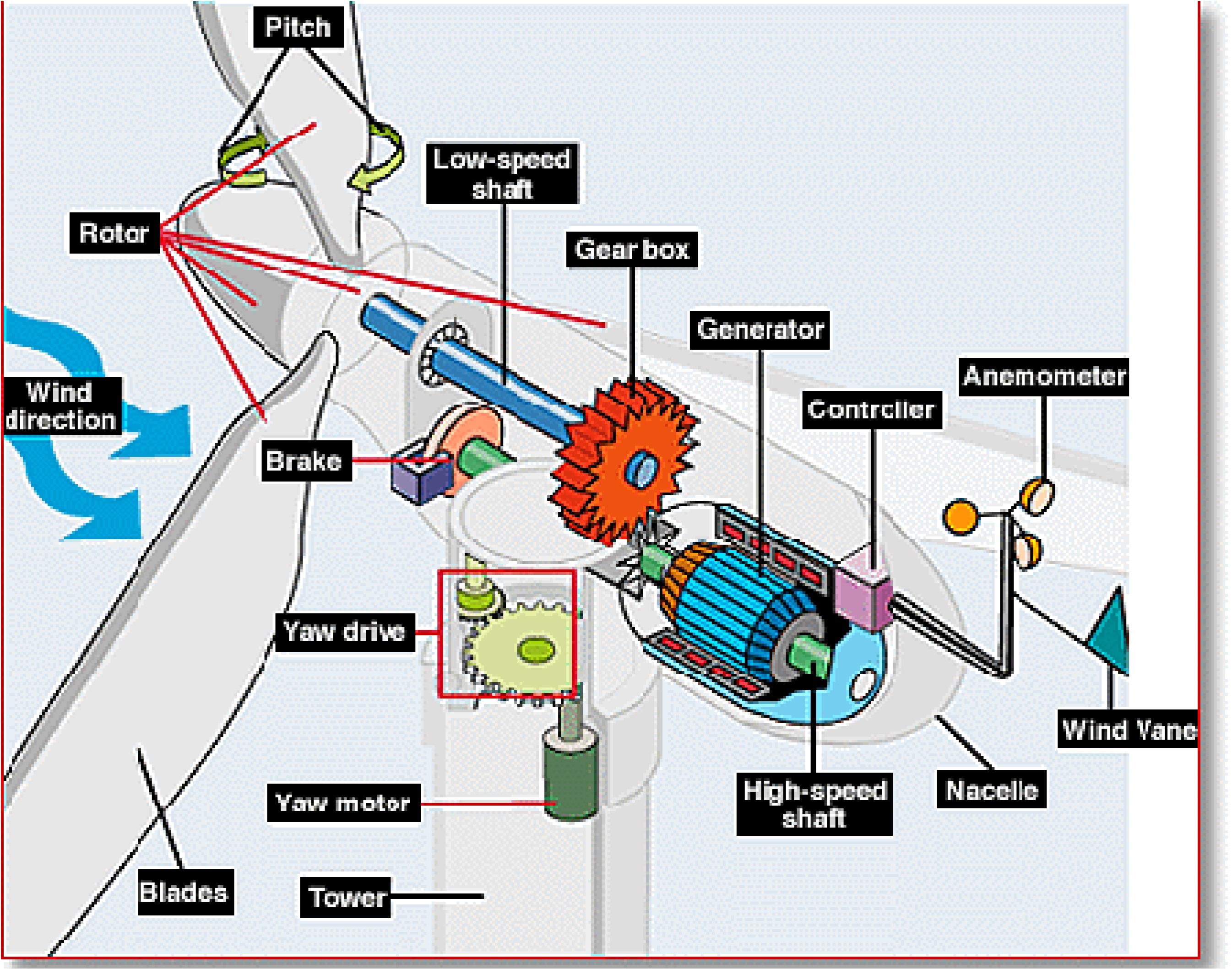

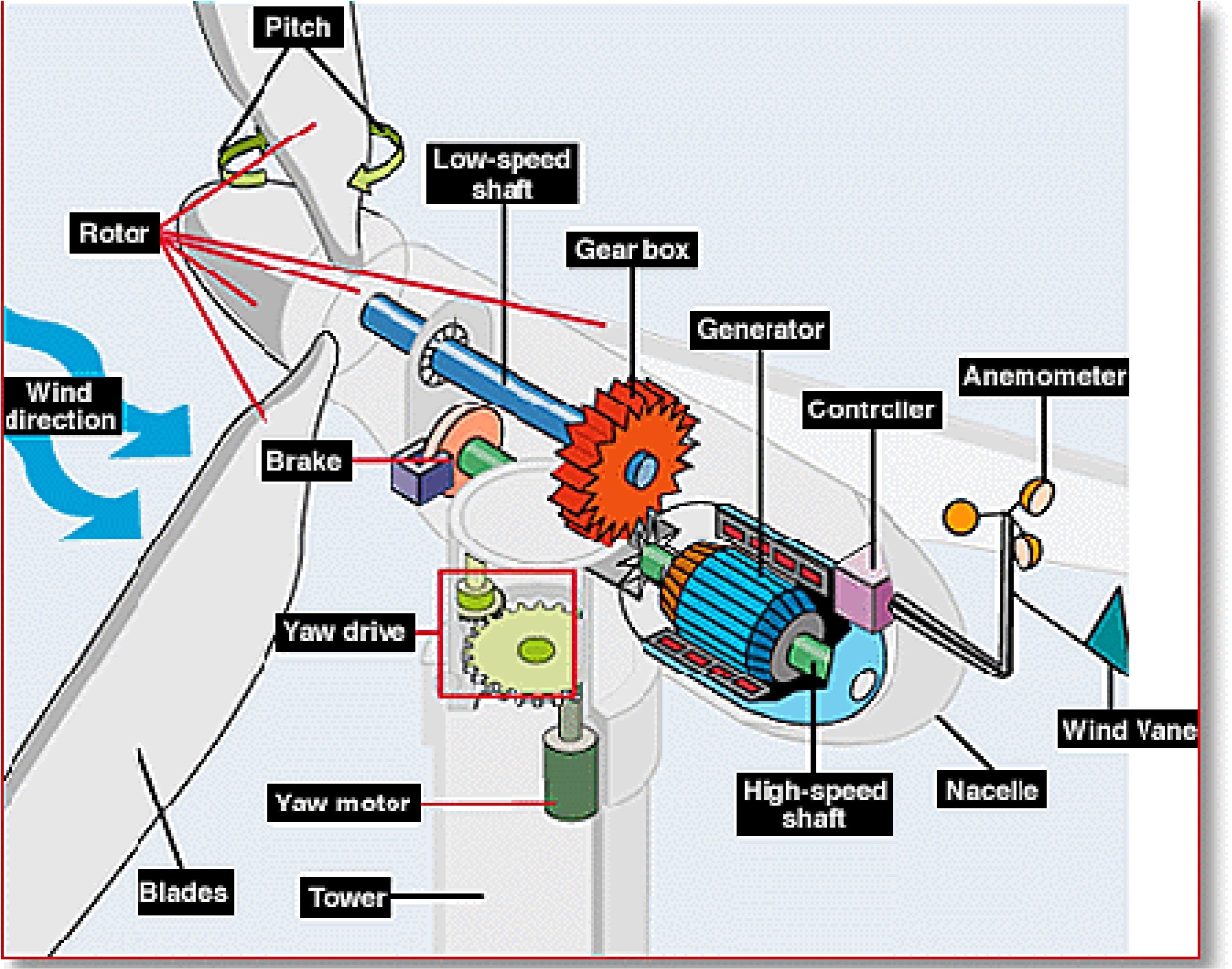

What does wind turbine contains or components of wind turbine?

Rotor:

Blades:

Blade is a

rotating component designed aerodynamically to work on the principle of lift

and drag to convert kinetic energy of wind into mechanical energy which is

transferred through shaft then converted to electrical energy using generator.

Most turbines have either two or three blades. Wind blowing over the blades

causes the blades to "lift" and rotate. Mechanical applications like

pumping water, grinding uses more number of blades as it requires more torque.

Blade length is key factor determining power generation capacity of a wind

turbine.

Nacelle:

The nacelle is an enclosure

that sits atop the tower and contains the gear box, low-speed shaft and

high-speed shaft, generator, controller, and brake. Some nacelles are large

enough for a helicopter to land on. The nacelle also protects turbine

components from atmospheric weather conditions and reduces noise.

Low-speed shaft:

Low-speed shaft is the

principle-rotating element which transfers torque from the rotor to the rest of

drive train. It also supports the weight of the rotor. It is connected to the

gearbox to increase the rpm.

Gear box:

Gear box steps

up the speed according to the requirement of the electric generator. Gears

connect the low-speed shaft to the high-speed shaft and increase the rotational

speeds from about 30 to 60 rotations per minute (rpm) to about 1000 to 1800

rpm, the rotational speed required by most generators to produce electricity.

The gear box is one of the costliest (and heavy) parts of the wind turbine and

there are also "direct-drive" generators that operate at lower

rotational speeds and don't need gear boxes.

Types: Planetary Gear Boxes, Parallel shaft gear.

High-speed shaft:

Transmits the speed & torque from the gearbox and drives the

generator.

Brake:

During the periods of

extremely high winds and maintenance, brakes are used to stop the wind turbine

for its safety.

Types of

Brakes: mechanical brake (Disc brake, clutch brake), Aerodynamic brake (Tip brake

and spoilers)

Generator:

Generator converts the

rotational mechanical energy into electrical energy. Usually wind electric

generator produces 50-cycle AC electricity.

Types:

Synchronous generator (Electrically excited, permanent magnet), asynchronous

generator (Squirrel cage, Slip ring)

Controller:

The controller starts up

the machine at cut-in wind speed (generally 3 m/s) and shuts off the machine at

cut-out wind speed (generally 25 m/s) as per the design requirement. The

controllers also operate the turbine to produce grid-quality electricity. The

controller measures and controls parameters like Voltage, current, frequency,

Temperature inside nacelle, Wind direction, Wind speed, The direction of

yawing, shaft speed, Over-heating of the generator, Hydraulic pressure level,

Correct valve function, Vibration level, Twisting of the power cable, Emergency

brake circuit, Overheating of small electric motors for the yawing, hydraulic

pumps, Brake-caliper adjustment etc.

Anemometer:

Anemometer is a

sensor used for measuring the wind speed. Other than using it for wind resource

assessment, it is normally fixed on top of the wind turbine to provide input to

the controller for power regulation and braking beyond the cut out &

survival wind speed .

Pitch:

Blades are turned or

pitched, out of the wind to control the rotor speed and keep the rotor from

turning in winds that are too high or too low to produce electricity.

Tower:

The tower

enables wind energy utilization at sufficient heights above ground, to absorb

and securely discharge static and dynamic stress exerted on the rotor, the

power train and the nacelle into the ground.

Types: Lattice tower, tubular tower, Guyed tower, Hybrid Tower

Foundation (not shown in

the picture)

Foundation is needed to support

and absorb the loads from the wind turbine. The choice of foundation type is

much dependent on the soil conditions and water table location prevailing at

the planned site of a wind turbine.

Onshore Foundation Types: Slab Foundation (preferred when the top soil is

strong), Pile Foundation (Preferred

when the top soil is of a softer quality)

Offshore Foundation Types: Monopile, Gravity base, Tripod

Wind vane:

Measures wind direction and

communicate with the controller for orienting the turbine properly (yawing)

with respect to the wind direction.

Yaw drive:

Yaw drive turns the nacelle

with rotor according to the wind direction using a rotary actuator engaging on

a gear ring beneath the nacelle. Yaw system keeps the turbine always facing the

wind.

Yaw motor:

Yaw motor is to power the yaw drive.

Related Topics