Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Testing Of Stones

Testing Of Stones

Building stones are available in large quantity in various

parts of the country and to choose and utilize them for their satisfactory

performance, it is necessary to test the stone for its strength properties,

durability and quality.

Durability Test: Some of

the tests to check the durability of stone are as follows. Of these tests, the

crystallization test is prescribed by Bureau of Indian Standards. The

durability (soundness) test is performed to find out the capacity of stone to

resist disintegration and decomposition.

Smith Test: Break off

the freshly quarried stone chippings to about the size of a rupee coin and put

them in a glass of clean water, one-third full. If the water becomes

slightly cloudy, the stone is good and durable. If water becomes dirty, it

indicates that the stone contains too much of earthy and mineral

matter.

Brard's Test -

for

frost resistance - Few small

pieces of freshly quarried stone are immersed in

boiling

solution of sulphate of soda (Glauber's salt) and are weighed. These are then

removed and kept

suspended for few days and

weighed again. The loss in weight indicates the probable effect of frost. Acid

Test - to check weather resistance - confirms

the power of stones to withstand the atmospheric conditions. 100 g of

stone chips are kept in a 5 per cent solution of H2SO4 or

HCI for 3 days. Then the chips are taken out and dried. The sharp and firm

corners and edges are indication of sound stone. This test is used to test the

cementing material of sand stone.

Crystallization

Test (IS 1126): Three test pieces of 50 mm diameter and 50 mm

height are dried for 24 hours and are weighed (W1). The

specimens are suspended in 14 per cent sodium sulphate solution (density 1.055

kg/m3) for 16 to 18 hours at room temperature (20 o to 30 o C). The

specimens are then taken out of the solution and kept in air for 4 hours. They

are then oven dried at a temperature of 105 o ± 5 o C for 24 hours and then cooled

at room temperature. This process is repeated for 30 cycles. The specimens are

weighed (W2) and the difference in weight is found. This test is

repeated thirty times and the loss in weight after every five cycles is

obtained. The change in weight indicates the degree of decay of stone. Durability

should be expressed in percentage as change in the weight. The average of three

test results should be reported as durability value.

Change in

weight = W2/W1

where W1 is the

original weight of the specimen and W2 is the weight of the specimen

after 30 cycles of the test.

Crushing Test

Compressive Strength Test (IS:

1121 (Part I)) Samples of stone weighing at least 25 kg each of

the unweathered spcimen should be obtained from quarry. To test stone

for compressive strength, specimen pieces in the form of cubes or cylinders are

made from samples of rock. The lateral dimension or diameter of test piece

should not be less than 50 mm and the ratio of height to diameter or lateral

dimension should be 1:1. A minimum of three specimen pieces are tested in each

saturated and dry conditions. Separate tests should be made for the specimen

when the load to parallel to the rift and perpendicular to the rift. In all

twelve test pieces should be used.

The

specimen pieces of diameter or lateral dimension 50 mm are immersed in water at

20 to 30 o C for 72 hours and are tested in saturated condition. The specimen

pieces are also tested in dry condition by drying them in an oven at 105 ± 5 o C

for 24 hours and then cooled in a desiccator to 20 -30 o C.

These are tested in universal testing machine. The load is applied gently at a

rate of 14 N/mm2 per minute until the resistance of the specimen

piece to the increasing load breaks down and no greater load is sustained.

The compressive strength of the

specimen piece is the maximum load in Newtons supported by it before failure

occurs divided by the area of the bearing face of the specimen in mm2.

The average of the three results in each condition separately should be taken

for the purpose of reporting the compressive strength of the sample.

When the

ratio of height to diameter or lateral dimension differs from unity by 25 per

cent or more, the compressive strength is calculated by the following

expression.

Cc=Cp /

EbO 0.778 0.222 É Ù Ê h Ú

where Cc =

compressive strength of standard specimen piece

Cp =

compressive strength of the specimen having a height greater than the diameter

or lateral dimension

b = diameter or lateral dimension

h = height

The crushing strength of stones varies in the range of 15-100 N/mm2.

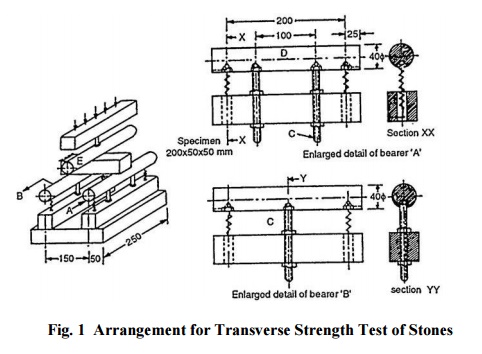

Transverse Strength Test (IS:

1121 (Part II)): To test stone for transverse strength, specimen

pieces are made in the form of blocks 200 × 50 × 50 mm. These are tested

in saturated and dry conditions similar to as explained in the compressive

strength test. Test apparatus used for testing is shown in Fig. 1. Each

specimen piece is supported upon two self-aligning bearers

A and B, 40 mm in diameter, the

distance between centres of bearers being 150 mm. Bearer A is supported

horizontally on two bearer screws C, which carry hardened steel balls D. Bearer

B is supported on one such bearer screw and ball. The load is then applied

centrally on the specimen piece at a uniform rate of 2 kN/min through a third

bearer E, also 40 mm in diameter, placed midway between the supports upon the

upper surface of the specimen S and parallel to the supports.

The

average of the three results (separately for saturated and dry condition)

should be taken for the purpose of determining transverse strength of sample.

Any specimen giving result as much as 15 per cent below the average value

should be examined for defects.

The

transverse strength of the specimen is given by

R = 3WL/2bd3

where R = transverse strength in N/mm2

W =

central breaking load in N

L =

length of span in mm

b =

average width in mm of the test piece at the mid section

d =

average depth in mm of the test piece at the mid section

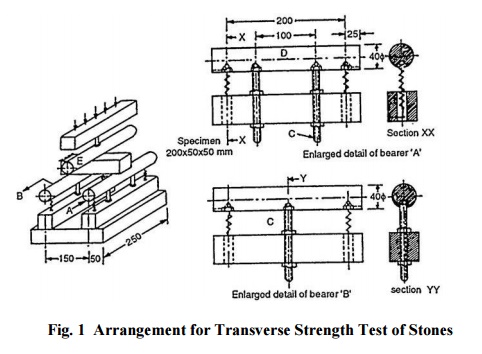

Tensile Strength Test (IS: 1121 (Part III))

Three

cylindrical test pieces of diameter not less than 50 mm and the ratio of

diameter to height 1:2 are used to determine the tensile strength of the stone

in each saturated (kept in water for 3 days at 20 to 30 o C) and dry condition

(dried in an oven at 105 ± 5 o C for 24 hours and cooled at room temperature).

The general arrangement for testing tensile strength of stone is shown in Fig.

3.11. Each test piece to be tested is sandwiched in between two steel plates of

width 25 mm, thickness 10 mm and length equal to the length of test piece. The

load is applied without shock and increased continuously at a uniform rate

until the specimen splits and no greater load is sustained. The maximum load

applied to the specimen is recorded.

Split

tensile strength,

S= 2W/SdL

where

S = split tensile strength (N/mm2) W = applied load

(N)

d = diameter of specimen (mm), and L = length of specimen (mm)

The

average of three results separately for each condition should be reported as

split tensile strength of the sample. In case any test piece gives a value of

as much as 15 per cent below the average, it should be examined for defects and

if found defective the test piece should be rejected.

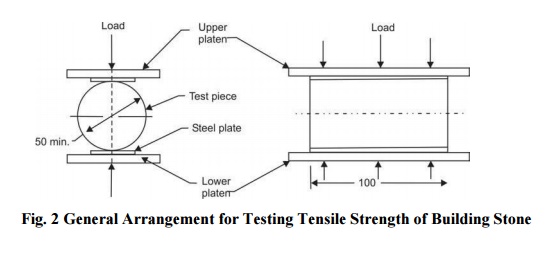

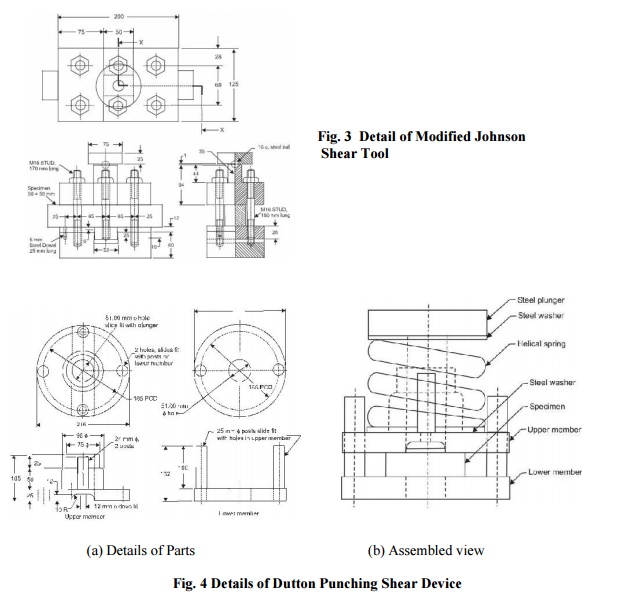

Shear Strength Test (IS: 1121 (Part IV))

The test is carried out either in

Jhonson shear tool (Fig. 3) or Dutton punching shear device (Fig. 4). Three

test pieces are used for conducting the test in each of the saturated and dry

condition.

Test piece for use in Jhonson

shear tool should be bars 50 × 50 mm in section and not less than 100 mm in

length and that for use with the Dutton punching shear device should be slabs

30 mm in thickness, 100 mm in width and not less than 100 mm in length.

Using Jhonson Shear Tool

The test

piece is carefully centred in the shear tool and the bolts drawn up tightly.

The tool is then centred in the testing machine with the centre of the

spherical block in contact with the centre of the top portion of the plunger of

the shear tool. The speed of the moving head of the testing machine during load

application should not be more than 1 mm/min. During the test, the beam of the

testing machine should be kept constantly in floating position. The shear

strength of test piece is calculated by

S=W/2A

where

S = Shear strength (N/mm2) W = total maximum load

(N)

A = area of the centre cross-section of test piece (mm2)

The average of all the three results separately

for each condition is calculated and taken as the shear strength of the test

piece.

Using Dutton Punching Shear Device

Centre

lines are laid over one surface of the slab. Thickness of the slab is measured

at three points approximately equidistant around the circumference of a 50 mm

circle centred on the intersection of the two center lines. The test piece is

centred in the punching device keeping it under the plunger. The punching

device is then centred in the testing machine with the centre of the spherical

bearing block in contact with the centre of the top portion of the plunger of

the shear device. The speed of the moving head of the testing machine during

load application should not be more than 1 mm/min. During the test, the beam of

the testing machine should be kept constantly in floating position. The shear

strength of the test piece is calculated by

S= WtWi SDT

where

S = Shear strength (N/mm2) Wt = total

maximum load (N)

Wi = initial load (N)

required to bring the plunger in contact with the surface of specimen D =

diameter (mm) of the plunger

T=

thickness (mm) of the specimen

The average of all the three results separately

for each condition is calculated and taken as shear strength of the test piece.

Absorption Test (IS: 1124)

The selected test pieces of stone are crushed or broken and

the material passing 20 mm IS Sieve and retained on 10 mm IS Sieve is used for

the test. The test piece weighing about 1 kg is washed to remove particles of

dust and immersed in distilled water in a glass vessel at room temperature 20

to 30 o C for 24 hours. Soon after immersion and again at the end of soaking period, entrapped air is removed by

gentle agitation achieved by rapid clock-wise and anti-clock-wise rotation of

the vessel. The vessel is then emptied and the test piece allowed to drain.The

test piece is then placed on a dry cloth and gently surface dried with the

cloth. It is transferred to a second dry cloth when the first one removes no

further moisture. The test piece is spread out not more than one stone deep on

the second cloth and left exposed to atmosphere away from direct sunlight or

any other source of heat for not less than 10 minutes untill it appears to be

completely surface dry. The sample is then weighed (B).

The sample is then carefully

introduced in a 1000 ml capacity measuring cylinder and distilled water is

poured by means of 100 ml capacity measuring cylinder while taking care to

remove entrapped air, untill the level of water in the larger cylinder reaches

1000 ml mark. The quantity of water thus added is recorded in ml or expressed

in gram weight (C).

The water

in the larger cylinder is drained and the sample is carefully taken out and

dried in an oven at 100 to 110 o C for not less than 24 hours. It is then cooled

in a desiccators to room temperature and weighed (A). The room temperature

during the test is recorded.

Apparent

specific gravity = A/1000C

Water

absorption = BA - 100 / A

Apparent

Porosity = BA-100 / C . 1000

The true

porosity shall be calculated from the following formula:

True

Porosity = [ True specific gravity - Apparent

specific gravity ] / True Specific

gravity

Where

A = Weight of oven-dry test piece (g)

B = Weight of saturated surface-dry test piece (g)

C = Quantity of water added in 1000 ml jar containing the test

piece (g)

Hardness: This test is performed by

scratching a stone with knife on Mohs scale.

Toughness:

This

test is performed by breaking the stone with a hammer. Toughness is indicated

by resistance to hammering.

Related Topics