Chapter:

Testing Of Cement: Physical Tests (IS: 4031)

Testing Of Cement: Physical Tests (IS: 4031)

Fineness Test

The degree of fineness of cement

is the measure of the mean size of the grains in it. There are three methods

for testing fineness: the sieve method-using 90

micron (9 No.) sieve, the air permeability method- Nurse

and Blains method and the sedimentation method- Wagner

turbidimeter method. The last two methods measure the surface area, whereas the

first measures grain size. Since cement grains are finer than 90 micron, the

sieve analysis method does not represent true mean size of cement grains. Also,

the tiny cement grains tend to conglomerate into lumps resulting in distortion

in the final grain size distribution curves. Considering these demerits,

fineness is generally expressed in terms of specific area, which is the total

surface area of the particles in unit weight of material.

Conditions Affecting Fineness:

The chemical composition and the degree of calcination influence the hardness

of the clinker and consequently the fineness to which the cement is ground.

Clinker, high in iron or silica, is apt to be hard and difficult to grind. The

same is true with a hard-burned clinker. Fineness is also influenced by the

time of grinding and the character of the pulverizing machinery. It has been

found that cement becomes finer with age provided it does not absorb too much

moisture. This is probably due to the decrepitation of the coarser grains

resulting from the hydration of the embedded lime particles.

Importance: Finer the cement,

more is the strength since surface area for hydration will be large. With

increase in fineness, the early development of strength is enhanced but the

ultimate strength is not affected. An increase in the fineness of the cement

increases the cohesiveness of the concrete mix and thus reduces the amount of

water which separates to the top of a lift (bleeding), particularly while

compacting with vibrators. However, if the cement is ground beyond a certain

limit, its cementative properties are affected due to the prehydration by

atmospheric moisture. Finer cement reacts more strongly in alkali reactive

aggregate. Also, the water requirement and workability will be more leading to

higher drying shrinkage and cracking.

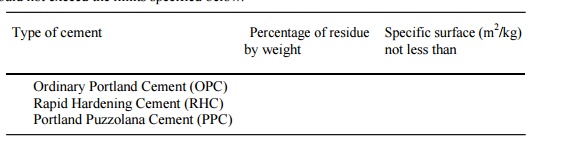

Sieve

Method: 100 g of cement sample is taken and air-set lumps, if any,

in the sample are broken with fingers. The sample is placed on a 90

micron sieve and continuously sieved for 15 minutes. The residue should not

exceed the limits specified below:

Air Permeability Method: The

fineness of cement is represented by specific surface, i.e. total surface area

in cm2 per gram or m2 per kilogram of cement and is

measured by Lea and Nurse apparatus or by wagner turbidimeter..

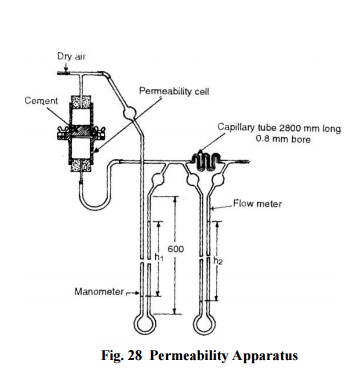

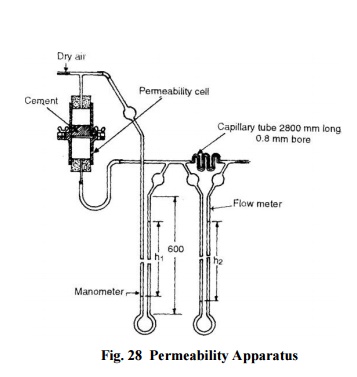

The Lea

and Nurse apparatus shown in Fig. 28 essentially consists of a permeability

test cell-where cement is placed and air pressure is

applied, flowmeter-to determine the quantity of air passing

per second through its capillary tube per unit difference of pressure, and

manometer-to measure the air pressure.

To

determine the fineness, a cement sample of 20 mm height is placed on a

perforated plate (40 micron perforations) and air pressure is applied. The

manometer is connected to the top of the permeability cell and the air is

turned on. The lower end of the permeability cell is then slowly connected to

the other end of the manometer. The rate of flow is so adjusted that the

flowmeter shows a pressure difference (h2) of 30-50 cm. The reading

(h 1) in the manometer is recorded. The process is repeated till the

ratio h1/h2 is constant. The specific surface is given by

the expression

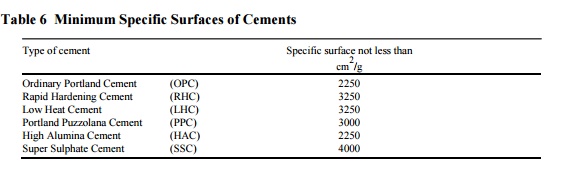

The minimum specific surface for various cements should be as

specified in Table 6.

Table 6 Minimum Specific Surfaces of Cements

Wagner Turbidimeter Method: L.A.Wagner

developed a turbidimeter to estimate the surface area of one gram of

cement. The cement is dispersed uniformly in a rectangular glass tank filled

with kerosene. Then, parallel light rays are passed through the solution which

strike the sensitivity plate of a photoelectric cell. The turbidity of the

solution at a given instant is measured by taking readings of the current

generated by the cell. By recording the readings at regular intervals while the

particles are falling in the solution, it is possible to secure information

regarding the grading in surface area and in size of particle. Readings are

expressed in sq. cm per gram.

Consistency Test

This is a test to estimate the quantity of mixing water to

form a paste of normal consistency defined as

that percentage water requirement of the cement paste, the

viscosity of which will be such that the

Vicat's plunger penetrates up to a point 5 to 7 mm

from the bottom of the Vicat's mould.

Importance: The water requirement

for various tests of cement depends on the normal consistency of the cement,

which itself depends upon the compound composition and fineness of the cement.

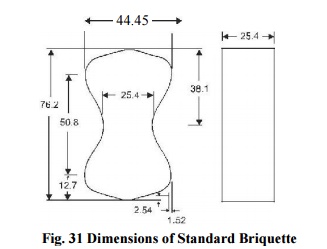

Test Procedure: 300 g of cement

is mixed with 25 per cent water. The paste is filled in the mould of Vicat's

apparatus (Fig. 29) and the surface of the filled paste is

smoothened and levelled. A square

needle 10 mm x 10 mm attached to

the plunger is then lowered gently over the cement paste surface and is

released quickly. The plunger pierces the cement paste. The reading on the

attached scale is recorded. When the reading is 5-7 mm from the bottom of the

mould, the amount of water added is considered to be the correct percentage of

water for normal consistency.

Determination of Initial and Final Setting Times

When water is added to cement,

the resulting paste starts to stiffen and gain strength and lose the

consistency simultaneously. The term setting implies solidification of the

plastic cement paste. Initial and final setting times may be regarded as the

two stiffening states of the cement. The beginning of solidification, called

the initial set, marks the point in time when the paste has become unworkable.

The time taken to solidify completely marks the final set, which should not be

too long in order to resume construction activity within a reasonable time

after the placement of concrete. Vicat's apparatus used for the purpose is

shown in Fig.. The initial setting time may be defined as the time taken by the

paste to stiffen to such an extent that the Vicat's needle is not permitted to

move down through the paste to within 5 ± 0.5 mm measured from the bottom of

the mould. The final setting time is the time after which the paste becomes so

hard that the angular attachment to the needle, under standard weight, fails to

leave any mark on the hardened concrete. Initial and final setting times are

the rheological properties of cement.

Importance: It is important to

know the initial setting time, because of loss of useful properties of cement

if the cement mortar or concrete is placed in moulds after this time. The

importance of final setting time lies in the fact that the moulds can be

removed after this time. The former defines the limit of handling and the

latter defines the beginning of development of machanical strength.

Conditions Affecting Setting

Time: The factors influencing the setting properties of cement are its

composition, the percentage of retardant, degree of calcination, fineness of

grinding, aeration subsequent to grinding clinker, percentage of water used to

make cement paste, the temperature of the mixing water, cement and the

atmosphere where the cement paste is placed, and the amount of manipulation the

paste receives.The effect of lime, silica and alumina in controlling the set have

been discussed in Sec. 5.3. The effect of gypsum is to increase the setting

time of freshly ground cement. It is usually mixed with the clinker before

final grinding, or just after the clinker has received preliminary grinding.

The addition of gypsum before calcination causes it to decompose into lime and

sulphur trioxide. Since the latter is liberated in the kiln, there is resulting

effect on the setting time. Often, an underlimed cement becomes quick setting

after seasoning. This can be avoided by adding to the cement 1 or 2 per cent of

hydrated lime or the fraction of a per cent of Plaster of Paris. Setting time

of cement is rapid with the increase in the fineness of cement. When the mixing

water used in testing cement paste is increased by 1 per cent above that

required for normal consistency, an increase of about 30 minutes or more is

observed in the initial or final set.

Cements stored in warm rooms

will, in general, be quick setting than those stored in cold places. Cold

mixing water retards set while warm water accelerates it. Cement exposed to

thoroughly saturated atmosphere will set much more slowly than those exposed to

a dry atmosphere. If, however, a considerable proportion of moist CO2

is present in the air, the setting time is found to reduce greatly. By

lengthening the time of mixing and by prolonged troweling of the surface

mortars, it is also possible to considerably delay the setting time.

Test Procedure: A neat cement

paste is prepared by gauging cement with 0.85 times the water required to give

a paste of standard consistency. The stop watch is started at the instant water

is added to the cement. The mould resting on a nonporous plate is filled

completely with cement

paste and the surface of filled

paste is levelled smooth with the top of the mould. The test is conducted

at room temperature of 27± 2 o C. The mould with the cement paste is placed in

the Vicat's

apparatus as shown in Fig. 5.9

and the needle is lowered gently in contact with the test block and is then

quickly released. The needle thus penetrates the test block and the reading on

the Vicat's

apparatus graduated scale is

recorded. The procedure is repeated until the needle fails to pierce the block

by about 5 mm measured from the bottom of the mould. The stop watch is pushed off

and the time is recorded which gives the initial setting time.

The

cement is considered to be finally set when upon applying the needle gently to

the surface of test block, the needle makes an impression, but the attachment

fails to do so.

Soundness Test

It is essential that the cement

concrete does not undergo large change in volume after setting. This is ensured

by limiting the quantities of free lime and magnesia which slake slowly causing

change in volume of cement (known as unsound). Soundness of cement may be

tested by Le-Chatelier method or by autoclave method. For OPC, RHC, LHC and PPC

it is limited to 10 mm, whereas for HAC and SSC it should not exceed 5 mm.

Importance: It is a very

important test to assure the quality of cement since an unsound cement produces

cracks, distortion and disintegration, ultimately leading to failure.

Conditions Affecting Soundness:

The main cause for unsoundness in Portland cement is the hydration of the

uncombined lime encased within the cement particles. Exposed, finely ground,

free lime in small percentages, hydrates before the cement sets and produces no

injurious effect. The uncombined lime in cement is a result of either

underburning the clinker or of excess lime in the raw materials. Freshly ground

cement is often unsound due to the presence of uncombined lime. Cement is thus

allowed to aerate for two to three weeks, allowing the lime to hydrate, to

overcome unsoundness.

Fine grinding of the raw material

and clinker help to produce a sound cement. By grinding fine the raw materials,

it is possible to produce a homogeneous mixture before burning where the lime

is uniformly distributed. The coarse grains of cement may imprison minute

particles of uncombined lime which do not hydrate. These lime particles on

hydralion produce disintegration.

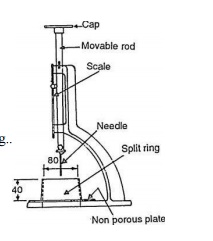

Le-chatelier

Method: The apparatus is shown in Fig. 30. The mould is placed on a

glass sheet and is filled with neat cement paste formed by gauging 100 g

cement with 0.78 times the water required to give a paste of standard

consistency. The mould is covered with a glass sheet and a small weight is

placed on the covering glass sheet. The mould is then submerged in the water at

temperature of 27 o -32 o C. After 24 hours, the mould is taken out and the

distance separating the indicator points is measured. The mould is again

submerged in water. The water is now boiled for 3 hours. The mould is removed

from water and is cooled down. The distance between the indicator points is

measured again. The difference between the two measurements represents the

unsoundness of cement.

Autoclave Test: The 25 ×

25 × 250 mm specimen is made with neat cement paste. After 24 hours the moulded

specimen is removed from the moist atmosphere, measured for length, and so

placed in an autoclave at room temperature that the four tides of each specimen

are at least exposed to saturated steam. The temperature of the autoclave is

raised at such a rate that the gauge pressure of the steam rises to 2.1 N/mm2

in 1 to 1 ¼ hours from the time the heat is turned on. The pressure is

maintained for 3 hours. Then the heat supply is shut off and the autoclave is

cooled at such a rate that the pressure is less than 0.1N/mm2 at the

end of the hour. The autoclave is then opened and the test specimens are placed

in water at temperature of 90 o C.The temperature is gradually brought down to

27±2 o C in 15 minutes. The specimens are maintained at this temperature for next

15 minutes and are then taken out. The length of the specimen is measured

again. The difference in the two measurements gives the unsoundness of the

cement.

Determination of Strength

Cement hydrates when water is

added to it and cohesion and solidity is exhibited. It binds together the

aggregates by adhesion. The strength of mortar and concrete depends upon the

type and nature of cement. So, it should develop a minimum specified strength if

it is to be used in structures. Cement is tested for compressive and tensile

strengths.

Conditions Affecting Strength:

Cement is very strong at early ages if a high lime or high alumina content is

there. Gypsum and Plaster of Paris in small percentages also tend to increase

the strength slightly, but when present in quantities larger then 3 per cent,

these substances provide variable effects. The effect of the clinker compounds

on strength have already been discussed. In addition to the effect of composition,

the strength of cement is greatly influenced by the degree of burning, the

fineness of grinding, and the aeration it receives subsequent to final

grinding. An underburnt cement is likely to be deficient in strength.

Compressive Strength: Compressive

strength is the basic data required for mix design. By this test, the quality

and the quantity of concrete can be cotrolled and the degree of adulteration

can be checked.

The test specimens are 70.6 mm

cubes having face area of about 5000 sq. mm. Large size specimen cubes cannot

be made since cement shrinks and cracks may develop. The temperature of water

and test room should be 27 o ± 2 o C. A mixture of cement and standard sand in the

proportion 1:3 by weight is mixed dry with a trowel for one minute and then

with water until the mixture is of uniform colour. Three specimen cubes are

prepared. The material for each cube is mixed separately. The quantities of

cement, standard sand and water are 185 g, 555 g and (P/4) + 3.5, respectively

where P = percentage of water required to produce a paste of standard

consistency. The mould is filled completely with the cement paste and is placed

on the vibration table. Vibrations are imparted for about 2 minutes at a speed

of 12000±4 00 per minute.

The cubes are then removed from

the moulds and submerged in clean fresh water and are taken out just prior to

testing in a compression testing machine. Compressive strength is taken to be

the average of the results of the three cubes. The load is applied starting

from zero at a rate of 35 N/sq mm/minute. The compressive strength is

calculated from the crushing load divided by the average area over which the

load is applied.The result is expressed in N/mm2. The minimum

specified strength for some of the cements is given in Table 5.4.

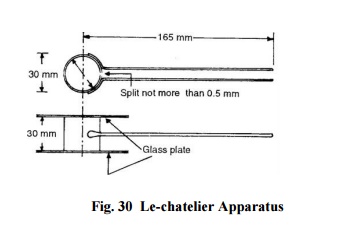

Table 7

Minimum Specified Strength in N/mm2

Tensile Strength: The

tensile strength may be determined by Briquette test method or by split tensile

strength test.

Importance: The

tensile strength of cement affords quicker indications of defects in the cement

than any other test. Also, the test is more conveniently made than the

compressive strength test. Moreover, since the flexural strength, is directly

related to the tensile strength this test is ideally fitted to give information

both with regard to tensile and compressive strengths when the supply for

material testing is small.

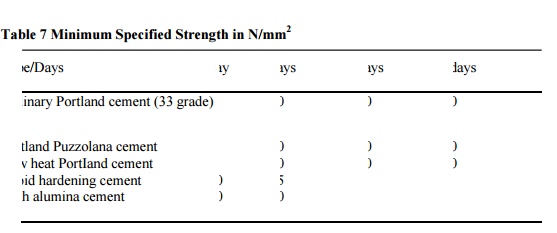

Briquette Method: A mixture

of cement and sand is gauged in the proportion of 1:3 by weight. The percentage

of water to be used is calculated from the formula (P/5) + 2.5, where P =

percentage of water required to produce a paste of standard consistency. The

temperature of the water and the test room should be 27 o ± 2 o C. The mix is

filled in the moulds of the shape shown in Fig. 5.11.

After

filling the mould, an additional heap of mix is placed on the mould and is

pushed down with the standard spatula, until the mixture is level with the top

of the mould. This operation is repeated on the other side of the mould also.

The briquettes in the mould are finished by smoothing the surface with the

blade of a trowel. They are then kept for 24 hours at a temperature of 27 o ±

2 o C and in an atmosphere having 90 per cent humidity. The briquettes are then

kept in clean fresh water and are taken out before testing. Six briquettes are

tested and the average tensile strength is calculated. Load is applied steadily

and uniformly, starting from zero and increasing at the rate of 0.7 N/sq mm of

section in 12 seconds.

Ordinary Portland cement should

have a tensile strength of not less than 2.0 N/mm2 after 3 days and

not less than 2.5 N/mm2 after 7 days.

Notes: (i) In the tension test of cement the load

on the briquette should be applied centrally. Since briquettes become brittle

with age, the effect of slight eccentricity or any torsional strain is

pronounced in long-time tests.

(ii) The strength increases when the loading rate

is increased from that specified.

Heat of hydration

Heat is evolved during hydration

of cement, the amount being dependent on the relative quantities of the clinker

compounds.

Importance: The evolution of heat

causes an increase in temperature of the concrete, being greatest in mass concreting.

Since the cooling of a mass of concrete can only occur from surfaces exposed to

atmosphere the temperature of the interior is higher than that at the surface

and also there is a rapid increase in strength in the interior than at the

surface. Shrinkage cracks may result from stresses, induced by cooling of the

surface while the interior of concrete is still at higher temperature. However,

in practice, the heat evolution may be taken to its advantage in cold weather

provided the concrete is warm at the time of placing and excessive heat loss is

prevented by suitable lagging.

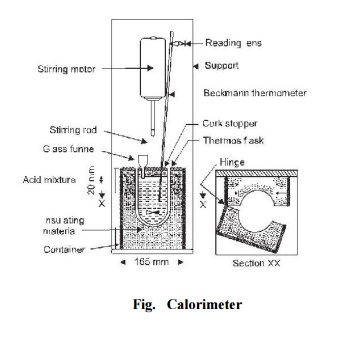

Test Procedure: The apparatus

used to determine the heat of hydration of cement is known as calorimeter and

is shown in Fig. 32. 60 g of cement and 24 ml of distilled water are mixed for

4 minutes at temperature 15 o -25 o C. Three specimen glass

vials 100 × 20 mm are filled with this mixture, corked and sealed with wax. The

vials are then stored with the mixture in a vertical position at 27 o ±2 o C. The

heat of hydration is obtained by subtracting the respective heat of solution of

unhyrated cement calculated nearest to 0.1 calorie.

For

determining the heat of solution of unhydrated cement, weigh a sample of about

3 g. At the same time, weigh out 7.0 g of cement for the loss on ignition.

Heat of solution (Cal/g) of unhydrated cement

where 0.2 is the specific heat of unhydrated cement.

For determining heat of solution

of the hydrated cement, one of the glass vials is opened and the adherent wax

is removed. The cement is ground rapidly, to avoid carbonation, to pass an 850

micron sieve. From this weigh out 4.2 g and 7.0 g of cement samples for heat of

solution and loss on ignition.

The heat

of solution of hydrated cement (Cal/g ignited weight)

Heat capacity

× corrected temperature

/ Weight of sample corrected for ignition M 0 M)

The ignition loss can be obtained

by placing the sample in a cool furnace and raising the temperature of the

furnace to 900 o C over a period of 1 hour. The sample is kept at 900 o ± 50 o C for

3 -4 hours and then cooled in a desiccator containing anhydrous calcium

chloride. Weigh after half an hour. The difference in the two weighings give

the loss on ignition.

To

determine the heat capacity sufficient quantity of zinc oxide is ignited for

one hour at 900 o ± 50 o C. It is cooled in a desiccator containing anhydrous

calcium chloride and ground to pass 250 micron sieve. About 7 g of this ignited

oxide is reheated to 900 o ± 50 o C for 5 minutes and then cooled for about 2½

hours (not more than 5 hours). The calorimeter is assembled and temperature

reading correct to 0.001 o C is recorded to determine the initial heating or

cooling correction. The zinc oxide is then introduced. The temperature readings

are recorded at one minute intervals until the solution is complete. The

recording of readings is continued for next 5 minutes to determine the final

heating or cooling correction. The initial and final heating or cooling rates

against the corresponding calorimeter temperature are plotted. The two points

thus obtained are joined by a straight line. From this graph the corrections

are read off for each temperature reading during the solution period. Heat

capacity is calculated from the expression.

Heat capcity (Cal/ o C)

= Weight of ZnO / Corrected temperature rise [256.10.1(30.0 \ 0 ) 0.1(\ 0

= Weight of ZnO (259.1 0.2\ 0.1\0 ) / Corrected

temperature rise

where, 256.1 is the heat of solution

of zinc oxide at 30 o C and 0.2 the negative temperature coefficient of the heat

of solution, is the final temperature of the calorimeter, 0.1 is the specific

heat of zinc oxide and is the room temperature in o C.

Specific Gravity Test

The

specific gravity of hydraulic cement is obtained using Le-Chatelier flask shown

in Fig. 5.13.

Conditions Affecting Specific

Gravity: Long seasonig is the chief cause of a low specific gravity in

unadulterated cement. This is because the freshly ground cement when exposed to

air rapidly absorbs moisture and carbon dioxide. Cements with high contents of

iron oxide have a higher specific gravity. The effect of fineness of grinding

upon specific gravity is slight. Very finely ground cements are likely to have

lower specific gravities.

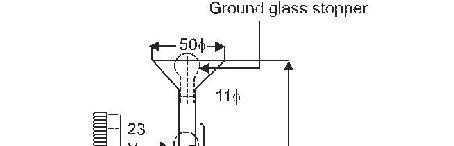

Test Procedure: The flask is

filled with either kerosene free of water, or naphtha having a specific gravity

not less than 0.7313 to a point on the stem between zero and 1-ml mark. The

flask is immersed in a constant temperature water bath and the reading is

recorded. A weighed quantity of cement (about 64 g of Portland cement) is then

introduced in small amounts at the same temperature as that of the liquid.

After introducing all the cement, the stopper is placed in the flask and the

flask rolled in an inclined position, or gently whirled in a horizontal circle,

so as to free the cement from air until no further air bubbles rise to the

surface of the liquid. The flask is again immersed in the water-bath and the

final reading is recorded. The difference between the first and the final

reading represents the volume of liquid displaced by the weight of the cement

used in the test.