Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

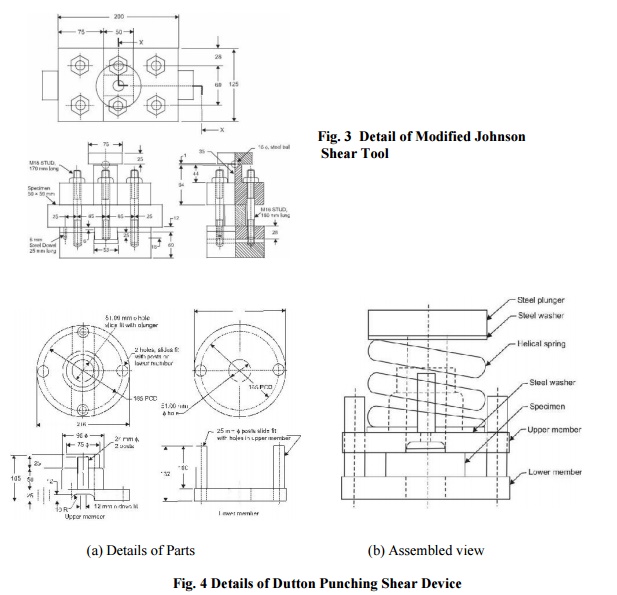

Shear Strength Test (IS: 1121 (Part IV)), Using Jhonson Shear Tool

Shear Strength Test (IS: 1121 (Part IV))

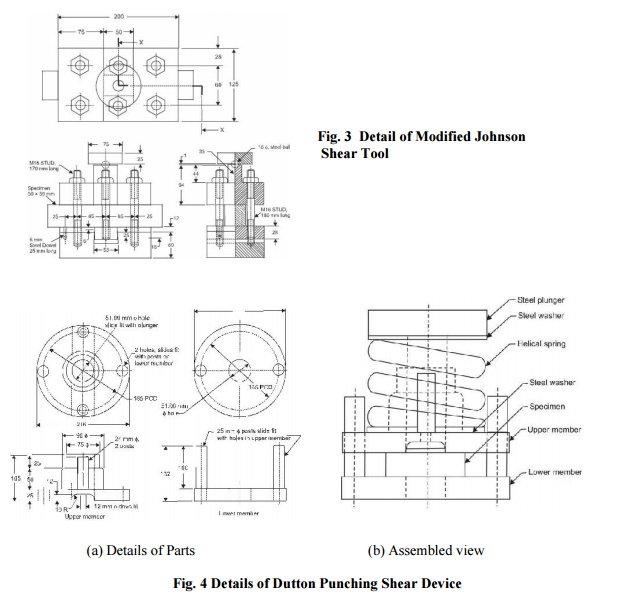

The test is carried out either in

Jhonson shear tool (Fig. 3) or Dutton punching shear device (Fig. 4). Three

test pieces are used for conducting the test in each of the saturated and dry

condition.

Test piece for use in Jhonson

shear tool should be bars 50 × 50 mm in section and not less than 100 mm in

length and that for use with the Dutton punching shear device should be slabs

30 mm in thickness, 100 mm in width and not less than 100 mm in length.

Using Jhonson Shear Tool

The test

piece is carefully centred in the shear tool and the bolts drawn up tightly.

The tool is then centred in the testing machine with the centre of the

spherical block in contact with the centre of the top portion of the plunger of

the shear tool. The speed of the moving head of the testing machine during load

application should not be more than 1 mm/min. During the test, the beam of the

testing machine should be kept constantly in floating position. The shear

strength of test piece is calculated by

S=W/2A

where

S = Shear strength (N/mm2) W = total maximum load

(N)

A = area of the centre cross-section of test piece (mm2)

The average of all the three results separately

for each condition is calculated and taken as the shear strength of the test

piece.

Using Dutton Punching Shear Device

Centre

lines are laid over one surface of the slab. Thickness of the slab is measured

at three points approximately equidistant around the circumference of a 50 mm

circle centred on the intersection of the two center lines. The test piece is

centred in the punching device keeping it under the plunger. The punching

device is then centred in the testing machine with the centre of the spherical

bearing block in contact with the centre of the top portion of the plunger of

the shear device. The speed of the moving head of the testing machine during

load application should not be more than 1 mm/min. During the test, the beam of

the testing machine should be kept constantly in floating position. The shear

strength of the test piece is calculated by

S= WtWi SDT

where

S = Shear strength (N/mm2) Wt = total

maximum load (N)

Wi = initial load (N)

required to bring the plunger in contact with the surface of specimen D =

diameter (mm) of the plunger

T=

thickness (mm) of the specimen

The average of all the three results separately

for each condition is calculated and taken as shear strength of the test piece.

Related Topics