Chapter:

Common types of Comparators

COMPARATORS

Comparators are one form of linear

measurement device which is quick and more convenient for checking large number

of identical dimensions. Comparators normally will not show the actual

dimensions of the work piece. They will be shown only the deviation in size.

i.e. During the measurement a comparator is able to give the deviation of the

dimension from the set dimension. This cannot be used as an absolute measuring

device but can only compare two dimensions. Comparators are designed in several

types to meet various conditions. Comparators of every type incorporate some

kind of magnifying device. The magnifying device magnifies how much dimension

deviates, plus or minus, from the standard size.

The comparators are classified according

to the principles used for obtaining magnification. The common types are:

1) Mechanical

comparators

2) Electrical

comparators

3) Optical

comparators

4) Pneumatic

comparators

1) MECHANICAL

COMPARATORS

Mechanical comparator employs mechanical

means for magnifying small deviations. The method of magnifying small movement

of the indicator in all mechanical comparators are effected by means of levers,

gear trains or a combination of these elements. Mechanical comparators are

available having magnifications from 300 to 5000 to 1. These are mostly used

for inspection of small parts machined to close limits.

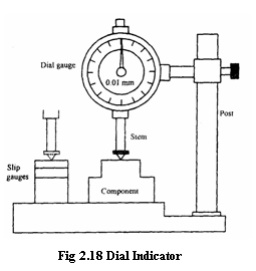

1. Dial indicator

A dial indicator or dial gauge is used

as a mechanical comparator. The essential parts of the instrument are like a

small clock with a plunger projecting at the bottom as shown in fig. Very

slight upward movement on the plunger moves it upward and the movement is

indicated by the dial pointer. The dial is graduated into 100 divisions. A full

revolution of the pointer about this scale corresponds to 1mm travel of the

plunger. Thus, a turn of the pointer b one scale division represents a plunger

travel of 0.01mm.

Experimental

setup

The whole setup consists of worktable, dial

indicator and vertical post. The dial indicator is fitted to vertical post by

on adjusting screw as shown in fig. The vertical post is fitted on the work

table; the top surface of the worktable is finely finished. The dial gauge can

be adjusted vertically and locked in position by a screw.

Procedure

Let us assume that the required height of the

component is 32.5mm. Initially this height is built up with slip gauges. The

slip gauge blocks are placed under the stem of the dial gauge. The pointer in

the dial gauge is adjusted to zero. The slip gauges are removed.

Now the component to be

checked is introduced under the stem of the dial gauge. If there is any

deviation in the height of the component, it will be indicated by the pointer.

Mechanism

The stem has rack

teeth. A set of gears engage with the rack. The pointer is connected to a small

pinion. The small pinion is independently hinged. I.e. it is not connected to

the stern. The vertical movement of the stem is transmitted to the pointer

through a set of gears. A spring gives a constant downward pressure to the

stem.

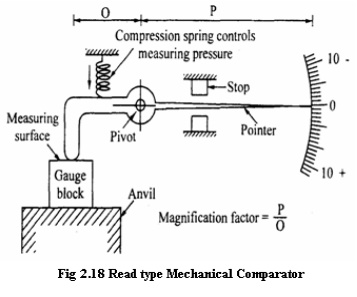

2.

Read type mechanical comparator

In this type of

comparator, the linear movement of the plunger is specified by means of read

mechanism. The mechanism of this type is illustrated in fig. A spring-loaded

pointer is pivoted. Initially, the comparator is set with the help of a known

dimension eg. Set of slip gauges as shown in fig. Then the indicator reading is

adjusted to zero. When the part to be measured is kept under the pointer, then

the comparator displays the deviation of this dimension either in ± or— side of

the set dimension.

Advantages

1) It

is usually robust, compact and easy to handle.

2) There

is no external supply such as electricity, air required.

3) It

has very simple mechanism and is cheaper when compared to other types.

4) It

is suitable for ordinary workshop and also easily portable.

Disadvantages

1)

Accuracy of the comparator mainly

depends on the accuracy of the rack and pinion arrangement. Any slackness will

reduce accuracy.

2) It

has more moving parts and hence friction is more and accuracy is less.

3)

The range of the instrument is limited

since pointer is moving over a fixed scale.

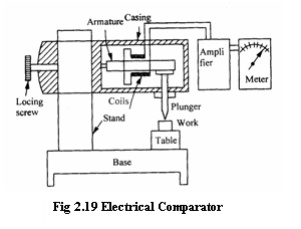

2) ELECTRICAL

COMPARATOR:

An

electrical comparator consists of the following three major part such as

1) Transducer

2) Display

device as meter

3) Amplifier

Transducer

An iron armature is provided in between

two coils held by a lea spring at one end. The other end is supported against a

plunger. The two coils act as two arms of an A.C. wheat stone bridge circuit.

Amplifier

The amplifier is nothing but a device

which amplifies the give input signal frequency into magnified output

Display

device or meter

The amplified input signal is displayed

on some terminal stage instruments. Here, the terminal instrument is a meter.

Working

principle

If the armature is centrally located

between the coils, the inductance of both coils will be equal but in opposite

direction with the sign change. Due to this, the bridge circuit of A.C. wheat

stone bridge is balanced. Therefore, the meter will read zero value. But

practically, it is not possible. In real cases, the armature may be lifted up

or lowered down by the plunger during the measurement. This would upset the

balance of the wheat stone bridge circuit. Due to this effect, the change in

current or potential will be induced correspondingly. On that time, the meter

will indicate some value as displacement. This indicated value may be either

for larger or smaller components. As this induced current is too small, it

should be suitably amplified before being displayed in the meter.

Checking

of accuracy

To check the accuracy of a given specimen or work,

first a standard specimen is placed under the plunger. After this, the

resistance of wheat stone bridge is adjusted so that the scale reading shows

zero. Then the specimen is removed. Now, the work is introduced under the

plunger. If height variation of work presents, it will move the plunger up or

down. The corresponding movement of the plunger is first amplified by the

amplifier then it is transmitted to the meter to show the variations. The least

count of this electrical comparator is 0.001mm (one micron).

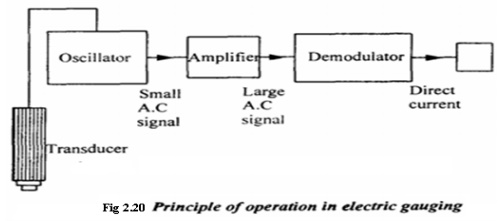

3)ELECTRONIC COMPARATOR

In electronic

comparator, transducer induction or the principle of application of frequency

modulation or radio oscillation is followed.

Construction

details

In

the electronic comparator, the following components are set as follows:

i. Transducer

ii. Oscillator

iii. Amplifier

iv.Demodulator

v. Meter

(i)

Transducer

It converts the

movement of the plunger into an electrical signal. It is connected with

oscillator.

(ii)

Oscillator

The oscillator which receives electrical

signal from the transducer and raises the amplitude of frequency wave by adding

carrier frequency called as modulation.

(iii)

Amplifier

An amplifier is connected in between

oscillator and demodulator. The signal coming out of the oscillator is

amplified into a required level.

(iv)

Demodulator

Demodulator is nothing but a device

which cuts off external carrier wave frequency. i.e. It converts the modulated

wave into original wave as electrical signal.

(v)

Meter

This is nothing but a display device

from which the output can be obtained as a linear measurement.

Principle

of operation

The work to be measured is placed under

the plunger of the electronic comparator. Both work and comparator are made to

rest on the surface plate. The linear movement of the plunger is converted into

electrical signal by a suitable transducer. Then it sent to an oscillator to

modulate the electrical signal by adding carrier frequency of wave. After that

the amplified signal is sent to demodulator in which the carrier waves are cut

off. Finally, the demodulated signal is passed to the meter to convert the

probe tip movement into linear measurement as an output signal. A separate

electrical supply of D.C. is already given to actuate the meter.

Advantages of

Electrical and Electronic comparator

1) It

has less number of moving parts.

2) Magnification

obtained is very high

3)

Two or more magnifications are provided

in the same instrument to use various ranges.

4) The

pointer is made very light so that it is more sensitive to vibration.

5) The

instrument is very compact.

Disadvantages of

Electrical and Electronic comparator

1) External

agency is required to meter for actuation.

2) Variation

of voltage or frequency may affect the accuracy of output.

3) Due

to heating coils, the accuracy decreases.

4) It

is more expensive than mechanical comparator.