Chapter: Mechanical : Strength of Materials : Thin Cylinders, Spheres and Thick Cylinders

Thin Cylinders, Spheres and Thick Cylinders

THIN CYLINDERS, SPHERES AND THICK CYLINDERS

Triaxial

Stress, Biaxial Stress, and Uniaxial Stress

Triaxial stress refers

to a condition where only normal stresses act on an element and all shear

stresses (txy, txz, and tyz) are zero. An

example of a triaxial stress state is hydrostatic pressure acting on a small

element submerged in a liquid.

A two-dimensional state of stress in which only two

normal stresses are present is called biaxial stress. Likewise, a

one-dimensional state of stress in which normal stresses act along one

direction only is called a uniaxial stress state.

Pure

Shear

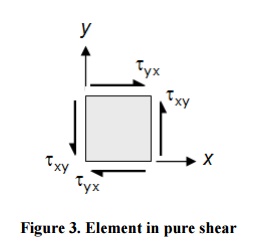

Pure shear refers to a stress state in which an

element is subjected to plane shearing stresses only, as shown in Figure 3.

Pure shear occurs in elements of a circular shaft under a torsion load.

Figure

3. Element in pure shear

Thin

cylindrical and spherical shells

Thin-walled

assumption

For the thin-walled assumption to be valid the

vessel must have a wall thickness of no more than about one-tenth (often cited

as one twentieth) of its radius. This allows for treating the wall as a

surface, and subsequently using the Young–Laplace equation for estimating the hoop stress created by an

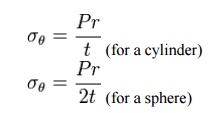

internal pressure on a thin wall cylindrical pressure vessel:

where

·

P is

the internal pressure

·

t is

the wall thickness

·

r is

the inside radius of the cylinder.

·

Ro Deta is the hoop stress.

The hoop stress equation for thin shells is also

approximately valid for spherical vessels, including plant cells and bacteria

in which the internal turgor pressure

may

reach several atmospheres.

Inch-pound-second system (IPS) units for P

are pounds-force

per square inch (psi). Units for t, and d

are inches (in). SI units for P are pascals

(Pa), while t and d=2r are in meters (m).

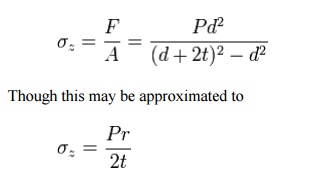

When the vessel has closed ends the internal

pressure acts on them to develop a force along the axis of the cylinder. This

is known as the axial stress and is usually less than the hoop stress.

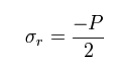

Also in this situation a radial stress is developed and may be estimated in thin

walled cylinders as:

Deformation

in thin cylindrical and spherical shells

Thick

cylinders and shells

Thick

Walled Cylinders

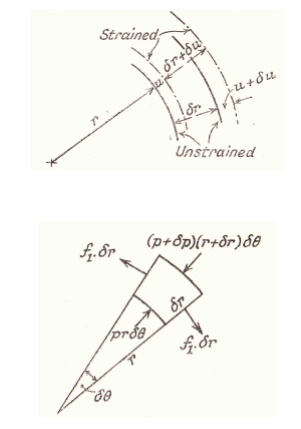

Under the action of radial Pressures at the

surfaces, the three Principal Stresses will be . These Stresses may be expected

to vary over any cross-section and equations will be found which give their

variation with the radius r.

It is assumed that the longitudinal Strain e is

constant. This implies that the cross-section remains plain after straining and

that this will be true for sections remote from any end fixing.

Let u be the radial shift at a radius r. i.e. After

Straining the radius r becomes (r + u). and it should be noted that u is small

compared to r.

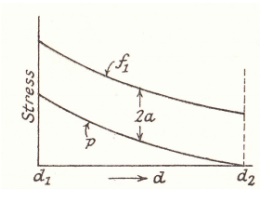

Internal Pressure Only

Pressure Vessels are found in all sorts of

engineering applications. If it assumed that the Internal and Pressure is at a

diameter of that the external pressure is zero ( Atmospheric) at a diameter

then using equation (22)

The Error In The "thin

Cylinder" Formula

If the thickness of the cylinder walls is t then and

this can be substituted into equation

Which

is 11% higher than the mean value given by And if the ratio is 20 then which is

5% higher than

It

can be seen that if the mean diameter is used in the thin cylinder

formula, then the error is minimal.

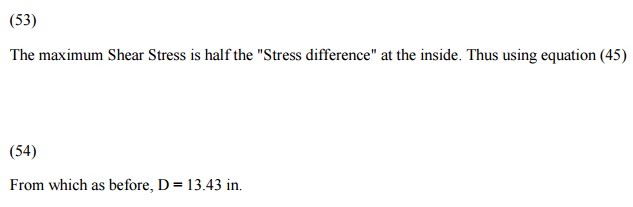

Example

1

The cylinder of a Hydraulic Ram has a 6 in. internal

diameter. Find the thickness required to withstand an internal pressure of 4

tons/sq.in. The maximum Tensile Stress is limited to 6 tons/sq.in. and the

maximum Shear Stress to 5 tons/sq.in.

If

D is the external diameter, then the maximum tensile Stress is the hoop Stress

at the inside.

Using equation (43)

Stresses

on inclined plane

Stresses

on inclined plane

procedure

to tackle stresses on inclined planes

STEPS:

In

order to do achieve the desired objective we proceed in the following manner

(i) Label

the Block ABCD.

(ii) Set

up axes for the direct stress (as abscissa) and shear stress (as ordinate)

(iii) Plot

the stresses on two adjacent faces e.g. AB and BC, using the following sign

convention.

tensile positive; compressive, negative Shear

stresses –tending to turn block clockwise, positive

–tending to turn block counter clockwise, negative

[ i.e shearing stresses are +ve when its movement

about the centre of the element is clockwise ]

This gives two points on the graph which may than be

labeled as respectively to denote stres

these planes.

(iv) Join AB bar and BC bar.

(v) The point P

where this line cuts the s axis is than the centre of Mohr's stress circle and

th joining AB bar and BC bar is diameter. Therefore the circle can now be

drawn.

Now every point on the circle then represents a

state of stress on some plane through C.

Principal

planes and stresses

Principal stresses and planes

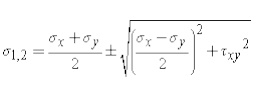

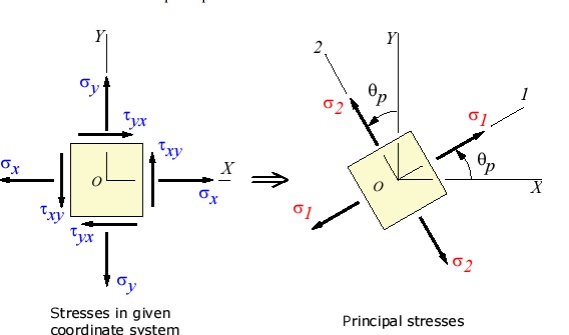

Principal Directions, Principal Stress

x' andy' (x'y') vary smoothly with respect to the

rotation accordance with the coordinate

transformation equations. There exist a couple of particular angles wher take

on special values.

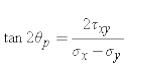

First, there exists an angle p where the shear

stress x'y' becomes zero. That angle is found by setting the above shear

transformation equation and solving for (set equal to p). The result is,

The angle p defines the principal directions where

the only stresses are normal stresses. These called principal stresses and are

found from the original stresses (expressed in the x,y,z directions) via,

The transformation to the principal directions can

be illustrated as:

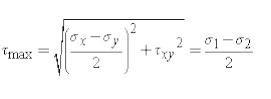

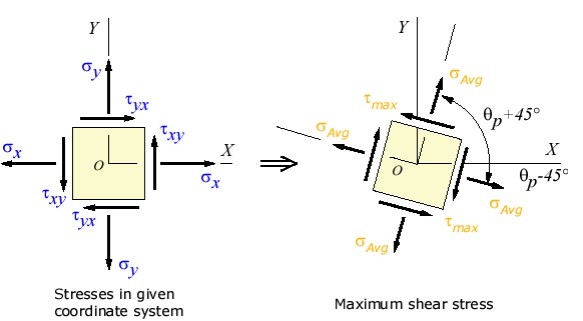

Maximum Shear Stress Direction

s, is where the maximum shear stress occurs. This is

found by finding the ma. Another important angle, shear stress transformation

equation, and solving for

The maximum shear stress is equal to one-half the

difference between the two principal stresses,

The transformation to the maximum shear stress

direction can be illustrated as:

Mohr’s

circle for biaxial

stress

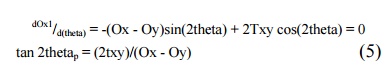

To find the maximum and

minimum normal stresses throughout the entire range of angles, one can easily

take the first derivative of (3) with respect to theta, set it to zero, and

solve for the angle. This will give what is called the principal plane

on which the principal

stresses act.

If this all sounds overly complicated... you're right! Why not just use the

tried and true terminology "maximizing and minimizing the

function" instead of inventing these two new terms with unrelated and

unclear meaning? Well.... that's civil engineers for you.

Where thetap defines the orientation of the principal planes, and its two

values, differing by 180o, are called the principal angles.

Now is where we begin to get into the unnecessary jargon. All the excess

baggage some engineer created to make it so that utilizing these relationships

would not require higher math. This (and many other examples of engineer

idioticy) most likely stems from the fact that most engineers slept through

their higher level math classes, and suffer from acute mathematical

insecurities (and probably rightly so.) It's these abstract constructions which

attempt to simplify the work, yet ultimately make it more difficult for those

of us more mathematically inclined, that really piss me off. If you represent

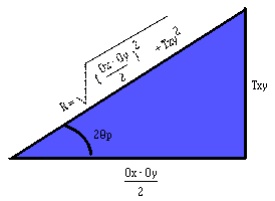

equation (5) geometrically with a 90o triangle, (left), we can obtain general

formulas for the principal stresses. First, we note that the hypotenuse of the

triangle is,

R = SQR{ [(Ox - Oy)/2]2

+ Txy2} (6)

The quantity R is defined as a positive number, and, like the other two

sides of the triangle, has the completely meaningless units of

"stress". From the triangle we obtain two additional relations:

cos(2thetap)

= (Ox - Oy)/(2R) sin(2thetap)

= Txy/R (7, 8)

Which is all very well

and good, because it actually leads to the USEFUL equation for the general

formula for the principal stresses:

O1,2 = (Ox +

Oy)/2 +/- R (9)

But such usefulness is

short lived as we approach MOHR'S CIRCLE..... Actually, Mohr's circle isn't all

that bad in many cases. It supplies its practitioners a clever and easy way to

compute otherwise hairy moments of inertia, allows strain analyses to be

handled quickly. However, in this case, its application seems to me a bit of a

stretch, and what you wind up with is this hopelessly complicated graphical

representation that seems so much more difficult than the original equations

(3) and (4) that it's hardly worth the effort to learn at all. HOWEVER....

because certain bastich

elements in the civil engineering department here at

the U of A

are requiring their students (many of whom, myself included, will NEVER use

these relationships again after the class has ended) to use this technique in

spite of the fact that we know of a perfectly valid and correct alternative.

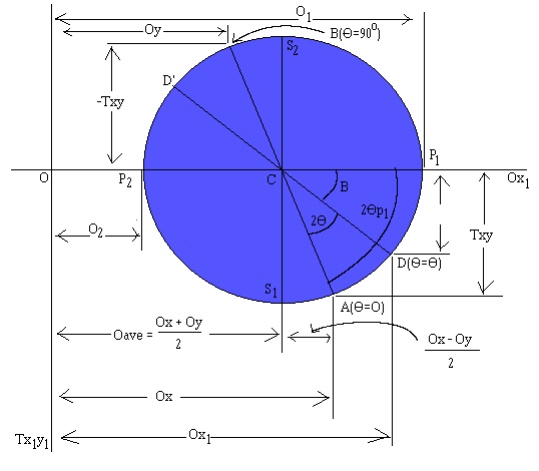

The equations of Mohr's

circle can be derived from the transformation equations (3) and (4). By simply

rearranging the first equation, we find that the two expressions comprise the

equation of a circle in parametric form.

Ox1 - (Ox +

Oy)/2 = [(Ox - Oy)/2]cos(2theta) + Txy sin(2theta) (10)

Tx1y1

= - {(Ox - Oy)/2}sin(2theta) + Txy cos(2theta)

(11)

To eliminate the 2theta

parameter, we square each relationship and add the two equations together. This

ultimately leads to (after simplification),

(Ox1 - {Ox +

Oy}/2)2 + Tx1y12 = {(Ox - Oy)/2}2

+ Txy2 (12)

However, by

resubstitution of equation (6) and by recognizing that the average stress value

between the X and Y axis, Oave, is,

Oave = (Ox + Oy)/2

equation (12) can be

simplified into the semi friendly equation of a circle in standard algebraic

form,

(Ox1 - Oave)2

+ Tx1y12 = R2 (13)

However, don't let this

nice looking equation for a circle fool you. Hidden in this simple equation are

some of the most hairy, complicated, and down-right nasty relationships I think

I have ever encountered. This makes my studies in the Frobenious theorem for

solving differential equations with non-constant singular coefficients seem

tame.

With Ox, Oy, and Txy

known, the procedure for constructing Mohr's circle is as follows:

1. Draw

a set of coordinate axis with Ox1 and Tx1y1

(with T positive downwards. From now on, for simplicity, O and T will represent

their respective axis.)

2. The

center of the circle, by equation (13) is located at T=0 and O=Oave. Oave is

nothing more than (12.a), so the center of the circle is located at:

C

= (Ox + Oy)/2

3. Locate

point A, representing the stress conditions on the X face of the normal

oriented element (Figure 1, extreme top left, non-rotated section). Plot

coordinates O = Ox, T = Txy. Here, it is important to note that at point A, the

inclination angle, theta, is zero.

4. Locate

point B, representing the stress conditions on the Y face of the normal

oriented element (Figure 1, again, extreme top left, non-rotated section).

Again, plot

coordinates O = Oy, T = Txy. Note that this point,

B, will be diametrically opposite from point A. Also note, that the angle of

inclination at B, theta, will be 90o, as it could also be achieved

on the X face by rotating it by 90o.

5. Draw

a line from point A to point B through the center C. This line is a diameter of

the circle.

6.

Using point C as the center, draw Mohr's

circle through points A and B. The circle will have a radius of R, which is the

same R as in equation (6).

Now that you have

Mohr's circle drawn, you can use it to analyze the problem. (Remember, that

this method is every bit as valid as simply using equations (3) and (4) above,

except it requires less mathematical skill, and many more memorized

relationships.)

O1,2,

representing the maximum and minimum normal stresses and their respective

angles away from point A (where theta = 0o) can be found by simply

looking at the O values when T = 0. In the drawing above, O1

represents the maximum, and O2 the minimum.

Furthermore, Tmax/min,

representing the maximum and minimum shear stresses and their respected angles

can be found by locating the T values when O = Oave. At this point, T is

simply equal to the radius, R, or equation (6).

In addition to these

helpful points, all other possible points for the shear and normal stresses can

be found on this circle. In order to find another value of Ox, Oy for a given

rotation, one must simply start at the A and B points (A representing the Ox value

and B, the Oy value), and rotate in a positive theta direction (by the

orientation shown above, this is in a counterclockwise direction, in keeping

with the right hand rule) for 2theta (from equations

(3) and (4) above). The

resulting points, D and D', will yield the Ox, Txy, and Oy, Txy (respectively)

for that rotation.

As I have likely

mentioned before (likely because, I can't really recall) to me this seems all

very abstract and difficult to use. However, the aforementioned bastiches will

be requiring this on my upcoming test, so I felt a need to more fully

understand it. Granted, I still don't understand it as fully as I would hope,

but it ought to be enough to get me through this one, insignificant little

test.

P.S.: I apologize for

my editorializing and opinionated presentation of this topic. I rarely do this

when I analyze problems I don't understand (even when I do not like the method,

such as the Lewis Dot

structure). This time, however, I have some very

strong feelings about my predicament. Also, in all fairness, if you were given

the problem where O1 = O2 and Tmax = 0, i.e. the Mohr's circle was simply a

little dot with R = 0, using the Mohr's circle method would arrive you at any

and all answers much quicker than using equations (3) and (4). However, I don't

think this extreme simplification of one special case warrants the abstraction

being a required bit of knowledge for civil engineers.

Related Topics