Chapter: Clinical Anesthesiology: Anesthetic Equipment & Monitors : The Operating Room Environment

The Operating Room Environment: Medical Gas Systems

Medical Gas Systems

The medical gases commonly used in

operating rooms are oxygen, nitrous oxide, air, and nitrogen. Although

technically not a gas, vacuum exhaust for waste anesthetic gas disposal (WAGD

or scavenging) and surgical suction must also be provided and is considered an

integral part of the medical gas system. Patients are endangered if medical gas

systems, par-ticularly oxygen, are misconfigured or malfunction. The main

features of such systems are the sources of the gases and the means of their

delivery to the operating room. The anesthesiologist must under-stand both

these elements to prevent and detect medical gas depletion or supply line

misconnection. Estimates of a particular hospital’s peak demand determine the

type of medical gas supply system required. Design and standards follow

National Fire Protection Association (NFPA) 99 in the United States and HTM

2022 in the United Kingdom.

SOURCES OF MEDICAL GASES

Oxygen

A reliable supply of oxygen is a

critical requirement in any surgical area. Medical grade oxygen (99% or 99.5%

pure) is manufactured by fractional distilla-tion of liquefied air. Oxygen is

stored as a compressed

gas at room temperature or refrigerated

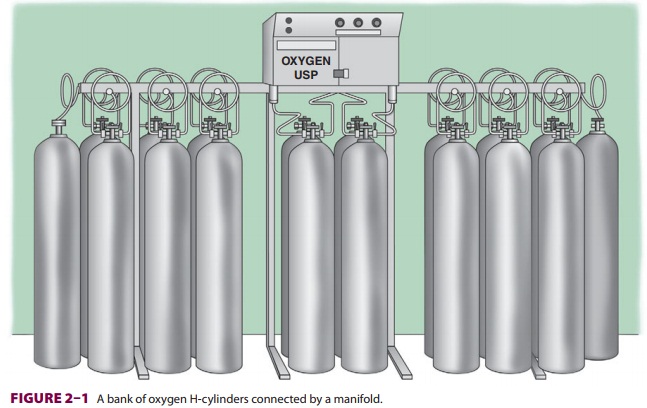

as a liquid. Most small hospitals store oxygen in two separate banks of high-pressure

cylinders (H-cylinders) con-nected by a manifold ( Figure 2–1). Only one bank is

utilized at a time. The number of cylinders in each bank depends on anticipated

daily demand. The manifold contains valves that reduce the cylinder pressure

(approximately 2000 pounds per square inch [psig]) to line pressure (55 ± 5 psig) and auto-matically switch banks when one

group of cylinders is exhausted.

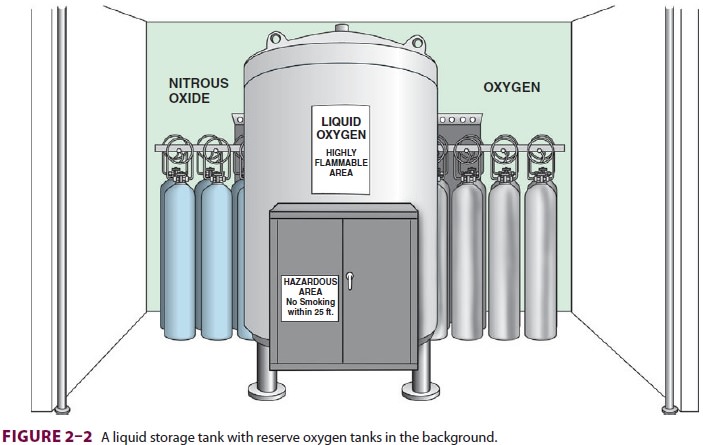

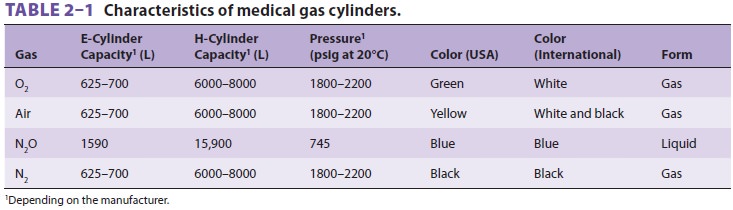

A liquid oxygen storage system (Figure 2–2) is more economical for large hospitals. Liquid oxygen must be stored well below its critical temperature of –119°C because gases can be liquefied by pressure only if stored below their critical temperature. A largehospital may have a smaller liquid oxygen supply or a bank of compressed gas cylinders that can provide one day’s oxygen requirements as a reserve. To guard against a hospital gas-system failure, the anesthesiolo-gist must always have an emergency (E-cylinder) sup-ply of oxygen available during anesthesia.Most anesthesia machines accommodate E-cylinders of oxygen (Table 2–1). As oxygen is expended, the cylinder’s pressure falls in proportionto its content. A pressure of 1000 psig indi-cates an E-cylinder that is approximately halffull and represents 330 L of oxygen at atmospheric pressure and a temperature of 20°C. If the oxygen is exhausted at a rate of 3 L/min, a cylinder that is half full will be empty in 110 min. Oxygen cylinder pressure should be monitored before use and peri-odically during use. Anesthesia machines usually also accommodate E-cylinders for medical air and nitrous oxide, and may accept cylinders of helium. Compressed medical gases utilize a pin index safety system for these cylinders to prevent inadvertent crossover and connections for different gas types. As a safety feature of oxygen E-cylinders, the yoke has integral components made from Wood’s metal. This metallurgic alloy has a low melting point, which allows dissipation of pressure that might otherwise heat the bottle to the point of ballistic explosion. This pressure-relief “valve” is designed to rupture at 3300 psig, well below the pressure E-cylinder walls should be able to with-stand (more than 5000 psig).

Nitrous Oxide

Nitrous oxide is manufactured by heating

ammo-nium nitrate (thermal decomposition). It is almost always stored by

hospitals in large H-cylinders con-nected by a manifold with an automatic

crossover feature. Bulk liquid storage of nitrous oxide is eco-nomical only in

very large institutions.

Because the critical temperature of nitrous oxide (36.5°C) is above room temperature, it can be kept liquefied without an elaborate refrig-eration system. If the liquefied nitrous oxide risesabove its critical temperature, it will revert to its gaseous phase. Because nitrous oxide is not an ideal gas and is easily compressible, this transfor-mation into a gaseous phase is not accompanied by a great rise in tank pressure. Nonetheless, as with oxygen cylinders, all nitrous oxide E-cylinders are equipped with a Wood’s metal yoke to preventvexplosion under conditions of unexpectedly high gas pressure (eg, unintentional overfilling), particu-larly during fires.

Although a disruption in supply is

usually not catastrophic, most anesthesia machines have reserve nitrous oxide

E-cylinders. Because these smaller cyl-inders also contain nitrous oxide in its

liquid state, the volume remaining in a cylinder is not propor-tional to cylinder pressure. By the time the liquid

nitrous oxide is expended and the tank pressure begins to fall, only about 400

L of nitrous oxide remains. If liquid

nitrous oxide is kept at a con-stant temperature (20°C), it will vaporize at

the same rate at which it is consumed and will main-tain a constant pressure

(745 psig) until the liquid is exhausted.

The only reliable way to determine

residual volume of nitrous oxide is to weigh the cylinder. For this reason, the

tare weight (TW), or empty weight, of cylinders containing a liquefied

com-pressed gas (eg, nitrous oxide) is often stamped on the shoulder of the

cylinder. The pressure gauge of a nitrous oxide cylinder should not exceed 745

psig at 20°C. A higher reading implies gauge malfunction, tank overfill (liquid

fill), or a cylinder containing a gas other than nitrous oxide.

Because energy is consumed in the

conversion of a liquid to a gas (the latent heat of vaporization), the liquid

nitrous oxide cools. The drop in tempera-ture results in a lower vapor pressure

and lower cyl-inder pressure. The cooling is so pronounced at high flow rates

that there is often frost on the tank, and pressure regulators may freeze.

Medical Air

The use of air is becoming more frequent

in anesthe-siology as the popularity of nitrous oxide and unnec-essarily high

concentrations of oxygen has declined. Cylinder air is medical grade and is

obtained by blending oxygen and nitrogen. Dehumidified but unsterile air is

provided to the hospital pipeline system by compression pumps. The inlets of

these pumps must be distant from vacuum exhaust vents and machinery to minimize

contamination. Because the critical temperature of air is –140.6°C, it exists

as a gas in cylinders whose pressures fall in proportion to their content.

Nitrogen

Although compressed nitrogen is not

administered to patients, it may be used to drive some operating room

equipment, such as saws, drills, and surgical handpieces. Nitrogen supply

systems either incorpo-rate the use of H-cylinders connected by a manifold or a

wall system supplied by a compressor driven central supply.

Vacuum

A central hospital vacuum system usually

consists of independent suction pumps, each capable of han-dling peak

requirements. Traps at every user location prevent contamination of the system

with foreign matter. The medical-surgical vacuum may be used for waste anesthetic

gas disposal (WAGD) provid-ing it does not affect the performance of the

system. Medical vacuum receptacles are usually black in color with white

lettering. A dedicated WAGD vacuum system is generally required with modern

anesthesia machines. The WAGD outlet may incorporate the use of a suction

regulator with a float indicator. The float should be maintained between the

designated markings. Excess suction may result in inadequate patient

ventilation, and insufficient suction levels may result in the failure to

evaluate WAGD. WAGD receptacles and tubing are usually lavender in color.

Carbon Dioxide

Many surgical procedures are performed

using lapa-roscopic or robotic-assisted techniques requiring insufflation of

body cavities with carbon dioxide, an odorless, colorless, nonflammable and

slightly acidic gas. Large cylinders containing carbon dioxide, such as

M-cylinders or LK-cylinders, are frequently found in the operating room; these

cylinders share a common size orifice and thread with oxygen cylin-ders and can

be inadvertently interchanged.

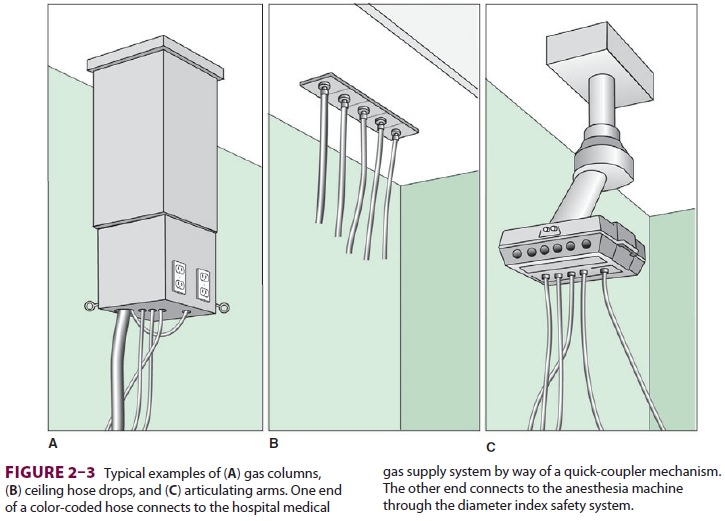

DELIVERY OF MEDICAL GASES

Medical

gases are delivered from their central sup-ply source to the operating room

through a piping network. Pipes are sized such that the pressure drop across

the whole system never exceeds 5 psig. Gas pipes are usually constructed of

seamless copper tubing using a special welding technique. Internal

contamination

of the pipelines with dust, grease, or water must be avoided. The hospital’s gas

deliv-ery system appears in the operating room as hose drops, gas columns, or

elaborate articulating arms (Figure 2–3). Operating room equipment,

including the anesthesia machine, interfaces with these pipe-line system

outlets by color-coded hoses. Quick-coupler mechanisms, which vary in design

with different manufacturers, connect one end of the hose to the appropriate

gas outlet. The other end connects to the anesthesia machine through a

non-interchangeable diameter index safety system fitting that prevents

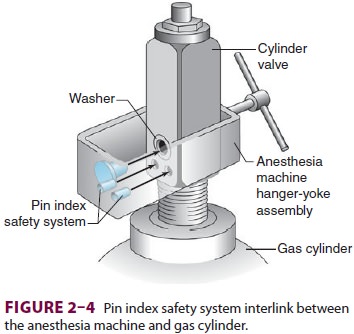

incorrect hose attachment.E-cylinders of oxygen, nitrous oxide, and air attach

directly to the anesthesia machine. To discourage incorrect cylinder

attachments, cylinder manufacturers have adopted a pin index safety system.

Each gas cylinder (sizes A–E) has two holes in its cylinder valve that mate

with correspondingpins in the yoke of the anesthesia machine (Figure 2–4).

The relative positioning of the pins and holes is unique for each gas. Multiple

washers placed between the cylinder and yoke, which prevent proper engagement

of the pins and holes, have unintention-ally defeated this system. The pin

index safety system is also ineffective if yoke pins are damaged or the

cyl-inder is filled with the wrong gas.

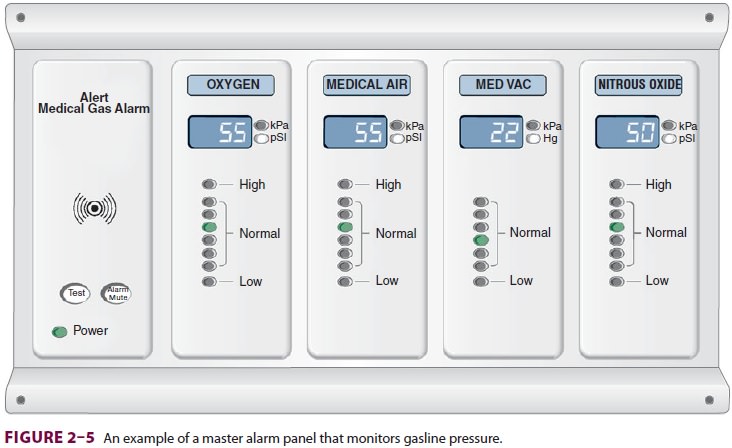

The

functioning of medical gas supply sources and pipeline systems is constantly

monitored by central and area alarm systems. Indicator lights and audible

signals warn of changeover to secondary gas sources and abnormally high (eg,

pressure regulator malfunction) or low (eg, supply depletion) pipeline

pressures (Figure

2–5).

Modern anesthesia machines and anesthetic gas analyzers continuously measure the fraction of inspired oxygen (FiO2). Analyzers have a variable threshold setting for the minimal FiO2 but should be configured to prevent disabling this alarm. The monitoring of FiO2 does not reflect the oxygen con-centration distal to the monitoring port and should not be used to reference the oxygen concentration within devices such as endotracheal tubes or at the distal tip of the tube. Due to gas exchange, flow rates, and shunting a marked difference can exist between the monitored FiO2 and oxygen concentration at the tissue level.

Related Topics