Chapter: Mechanical and Electrical : Thermal Engineering : Steam Nozzles and Turbines

Solved Problems: Steam Nozzles and Turbines

Solved Problems:

1. A convergent divergent adiabatic steam nozzle is supplied with steam at 10 bar and 250°c.the discharge pressure is 1.2 bar.assuming that the nozzle efficiency is 100% and initial velocity of steam is 50 m/s. find the discharge velocity.

Given Data:-

Initial pressure(p1)=10bar Initial

Temperature(T1)=250°c

Exit pressure(p2)=1.2 bar

Nozzle efficiency(ηnozzle)=100%

Initial velocity of steam (v1)=50m/s

To Find:-

Discharge velocity (v2)

Solution:-

From steam table, For 10 bar, 250°c, h1=2943 KJ/kg s1=6.926 KJ/kgk

From steam table, For 1.2 bar,

hf2 =439.3 KJ/kg ; hfg2=2244.1 KJ/kg;

sf2=1.3 61 KJ/kg K ; sfg2=5.937 KJ/kgK.

Since s1=s2,

S1=sf 2+x2sfg2

6.926=1.361+x2(5.937)

X2=0 .9373

We know that,

h2=hf2+x2hfg2

= 439.3+(0.9373)2244.1

h2 = 2542KJ/Kg

Exit velocity (V2) = Rt[(2000(2943) 2542) + 502]

= 896.91m/s.

2. Dry saturated steam at 6.5 bar with negligible velocity expands isentropically in a convergent divergent nozzle to 1.4 bar and dryness fraction 0.956. De termine the final velocity of steam from th e nozzle if 13% heat is loss in friction. Find th e % reduction in the final velocity.

Given data:

Exit pressure (P2) = 1.4 bar

Dryness fract ion (X2) = 0.956

Heat loss = 13%

To Find:

The percent reduction in final velocity

Solution:

From steam table for initial pressure P1 = 6.5bar, take values h1 =

h1 = 2758.8KJ/Kg

Similarly, at 1.4 bar,

hfg2 = 2231.9 KJ/Kg

hf2 = 458.4KJ/Kg

h2 = hf2 + X2 hfg2

= 458.4 + (0.956) 2231.6

h2 = 2592.1 KJ/Kg

Final velocit y (V2) = Rt (2000(h1-h2) )

V2 = 577.39 m/s

Heat drop is 13%= 0.13

Nozzle efficiency (η) = 1- 0.13 = 0.87

Velocity of s team by considering the nozzle efficiency,

y (V2) = Rt (2000(h1-h2) ) x η

V2 = 538.55 m/s

= % reductio n in final velocity = 6.72%

3.A convergent divergent nozzle receives steam at 7bar and 200oc and it expands isentropically into a space of 3bar neglecting the inlet velocity calculat e the exit area required for a mass flow of 0.1Kg/sec . when the flow is in equilibrium through all and super saturated with PV1.3=C.

Given Data:

Initiall pressure (P1) = 7bar = 7× 105N/m2

Initiall temperature (T1) = 200oC

Press ure (P2) = 3bar = 3× 105N/m2

Mass flow rate (m) = 0.1Kg/sec

PV1.3 =C

To Find:

Exit area

Solution:

From st eam table for P1 = 7bar and T1 = 200oC V1 =

0.2999

h1 = 2844.2

S1 = 6.886

Similarly for P2 = 3bar

Vf2 = 0.001074 Vg2 = 0.60553 hf2 =

561.5 hfg2 = 2163.2

Sf2 = 1.672 Sfg2 = 5.319

We know that, S1 = S2 = St

S1 = Sf2 + X2 Sfg2

6.886 = 1.672 + X2 (5.319) X2 =

0.98

Similarly,

h2 = hf2 + X2 hfg2

h2 = 561.5 + 0.98 (2163.2)

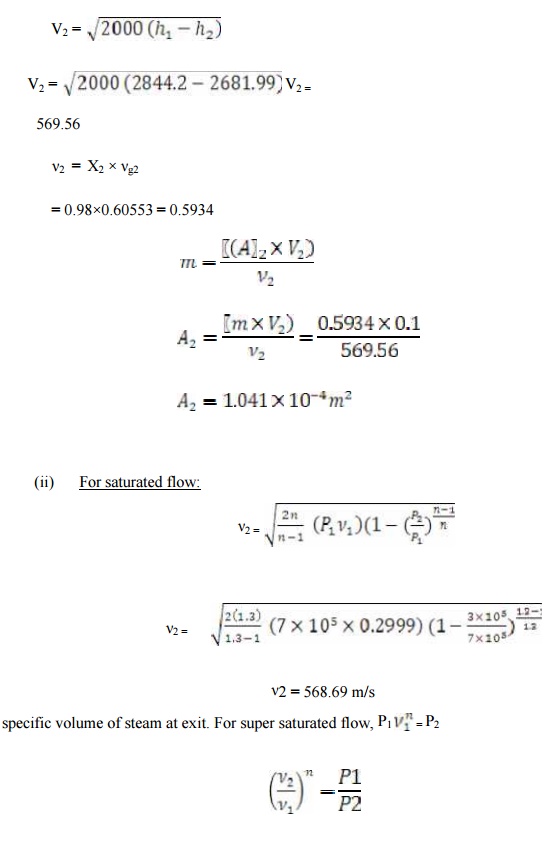

(i) Flow is in equilibriu m through all:

V2=569.56

ν2 = X2 × νg2

= 0.98× 0.60553 = 0.5934

TECHNICAL TERMS

1.Diaphragm - Partitions b etween pressure stages in a turbine's casing.

2. Radial - flow turbine - st eam flows outward from the shaft to the casing.

3. Radial clearance - cleara nce at the tips of the rotor and casing.

4. Axial clearance - the fore -and-aft clearance, at the sides of the rotor and t he casing.

5. balance piston - Instead of piston, seal strips are also used to duplicate a piston's counter force.

6. steam rate - The steam rate is the pounds of steam that must be supplied per kilowatt-hour of generator output at the steam turbine inlet.

7. extraction turbine - ste am is withdrawn from one or more stages, at one or more pressures, for heating, pl ant process, or feedwater heater needs.

8. Wet steam: The steam w hich contains some water particles in superposition.

9. Dry steam / dry saturated steam: When whole mass of steam is converted into steam then it is called as dry steam.

10. Super heated steam: When the dry steam is further heated at consta nt pressure, the temperature increases the above saturation temperature. The steam has obtained is called super heated stea m.

11. Degree of super heat: The difference between the temperature of saturated steam and saturated temperature is c alled degree of superheat.

12. Nozzle:It is a duct of varying cross sectional area in which the velocity increases with the corresponding drop in pressure.

13. Coefficient of nozzle: It is the ratio of actual enthalpy drop to isentropic enthalpy drop.

14. Critical pressure ratio: There is only one value of ratio (P2/P1) which produces maximum discharge fro m the nozzle . then the ratio is called critica l pressure ratio.

15. Degree of reaction: It is defined as the ratio of isentropic heat drop in th e moving blade to isentrpic heat drop in the entire stages of the reaction turbine.

16. Compounding: It is the method of absorbing the jet velocity in stages when the steam flows over moving blades. (i)Velocity compounding (ii)Pressure compounding and (iii) Velocity-pressure compounding

17. Enthalpy: It is the combination of the internal energy and the flow energy.

18. Entropy: It is the function of quantity of heat with respective to the temperature.

19. Convergent nozzle: The crossectional area of the duct decreases from inlet to the outlet side then it is called as convergent nozzle.

20. Divergent nozzle: The crossectional area of the duct increases from inlet to the outlet then it is called as divergent nozzle.

Related Topics