Chapter: civil : Design Of Steel Structures

Shear Connections With Bearing Type Bolts

SHEAR CONNECTIONS WITH BEARING TYPE

BOLTS

In this section the

force transfer mechanisms of bearing and friction type of bolted connections

are described.

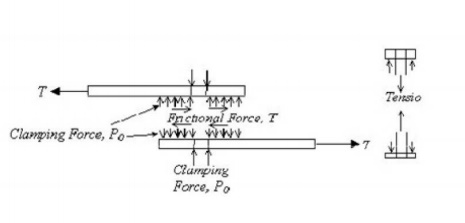

1. Force transfer of bearing type bolts

Figure 13 shows the

free body diagram of the shear force transfer in bearing type of bolted

connection. It is seen that tension in one plate is equilibrated by the bearing

stress between the bolt and the hole in the plate. Since there is a clearance

between the bolt and the hole in which it is fitted, the bearing stress is

mobilised only after the plates slip relative to one another and start bearing

on the bolt

.The

section x-x in the bolt is critical section for shear. Since it is a lap joint

there is only one critical section in shear (single shear) in the bolt .In the

case of butt splices there would be two critical sections in the bolt in shear

(double shear), corresponding to the two cover plates.

2. Design shear strength of bearing type

bolts

The failure of

connections with bearing bolts in shear involves either bolt failure or the

failure of the connected plates. In this section, the failure modes are

described along with the codal provisions for design and detailing shear

connections. In connections made with bearing type of bolts, the behaviour is

linear until

i) yielding takes place

at the net section of the plate under combined tension and flexure or

ii) shearing takes place at the bolt shear

plane or

iii) failure of bolt

takes place in bearing,

iv) failure of plate

takes place in bearing and

v) block shear failure

occurs. Of these,

i) and will be

discussed in the chapter on tension members. The remaining three are described

below.

3.

Shearing of bolts

The

shearing of bolts can take place in the threaded portion of the bolt and so the

area at the root of the threads, also called the tensile stress area At, is

taken as the shear area As. Since threads can occur in the shear plane, the

area Ae for resisting shear should normally be taken as the net tensile stress

area, An, of the bolts. The shear area is specified in the code and is usually

about 0.8 times the shank area. However, if it is ensured that the threads will

not lie in the shear plane then the full area can be taken as the shear area. A

bolt subjected to a factored shear force (Vsb) shall satisfy as per cl. 10.3.2 of IS 800:2007, where . 10.3.3 of the code.

Here Vnsb = nominal

shear capacity of a bolt, calculated by in which fu =

ultimate tensile strength of a bolt; nn = number of shear planes

with threads intercepting the shear plane; n, = number of shear planes without

threads intercepting the shear plane; Asb = nominal plain shank area

of the bolt; and Anb = net shear area of the bolt at threads, may be

taken as the area corresponding to root diameter at the thread as given in

Table 5 and ?mb = 1.25.

For bolts in single shear, either nn or ns is one and the

other is zero. For bolts in double shear the sum of nn and ns

is two.

Table 5

Tensile area of ordinary bolts (Grade 4.6)

Bolt

size, d (mm) 12 16 20 22 24 27 30 36

Tensile

stress area (mm2) 84.3 157 245 303 353 459 561 817

2.2. Bearing failure

If the connected plates are made

of high strength steel then failure of bolt can take place by bearing of the

plates on the bolts. If the plate material is weaker than the bolt material,

then failure will occur by bearing of the bolt on the plate and the hole will

elongate. The beating area is given by the nominal diameter of the bolt times

the combined thickness of the plates bearing in any direction. A bolt bearing

on any plate subjected to a factored shear force (Vsb) shall satisfy as Vsb < = Vdb per cl. 10.3.2 of IS 800:2007,

where as Vdb = Vdpb = Vnpb/?mb given by cl. 10.3.4 of the code where, ?mb = 1.25

and Vnpb = bearing strength of a bolt, calculated as Vnpb

= 2.5kbdtfu where fu = smaller of the ultimate

tensile stress of the bolt and the ultimate tensile stress of the plate, d =

nominal diameter of the bolt, t = summation of the thicknesses of the connected

plates experiencing bearing stress in the same direction and kb is

smaller of e/3d0, p/3d0-0.25, fub/fu,

1.0 where e, p = end and pitch distances of the fastener along bearing

direction; d0 = diameter of the hole; fub, fu

= Ultimate tensile stress of the bolt and the ultimate tensile stress of the

plate, respectively.

The underlying assumption behind

the design of bolted connections, namely that all bolts carry equal load is not

true in some cases. In long joints, the bolts farther away from the centre of

the joint will carry more load than the bolts located close to the centre.

Therefore, for joints having more than two bolts on either side of the building

connection with the distance between the first and the last bolt

exceeding 15d in the direction of load, the nominal shear

capacity Vns, shall be reduced by the factor,

?lj, given by

(Cl.10.3.2.1) ?lj = 1.075 -

lj / (200 d) but 0.75 < ?lj

<

1.0 where, d= nominal diameter of the bolt Similarly, if

the grip length exceeds five times the nominal diameter, the strength is

reduced as specified in IS 800. In multi-bolt connections, due to hole

mismatch, all the bolts may not carry the same load. However, under ultimate

load, due to high bearing ductility of the plates considerable redistribution

of the load is possible and so the assumption that all bolts carry equal load

may be considered valid.

Related Topics