Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

Seven tools of quality

SEVEN

TOOLS OF QUALITY

Prerequisite

Discussion

·

The quality of a product or service depends on the

quality of process employed.

·

Every organization needs to establish a set of

well-defined process for manufacturing of product (or) design or service.

·

The objective of process control is to control the

quality of the processes and ensure that the deliverables are produced as

planned.

·

Aim of the statistical based process control is to

produce products and services with quality consistently.

·

Seven quality control tools are very important for

continuous improvement in the TQM journey.

·

It is a prerequisite for ISO 9000 certification

process flow charts are insisted and the organizations are asked to document

the processes.

Concept

There are many proposed tools and techniques to achieve the

TQM promises. Generally, a technique can be considered as a number of

activities performed in a certain order to reach the values .

On the other hand, tools sometimes have statistical basis to

support decision making or facilitate analysis of data.

The best tools for this purpose is check sheet, Pareto chart,

histogram, scatter diagram, run chart and statistical process control (SPC).

The data collected by these tools can be used to measure the

process. The correct selection and use of tools and techniques is a vital

component of any successful TQM implementation plan.

The TQM tools and techniques can be divided into simple tools

for solving a special problem and complex one that cover all functions within

the company.

Flow

Charts

This is

one of the basic quality tool that can be used for analyzing a sequence of

events.

The tool maps out a sequence of events that take place

sequentially or in parallel. The flow chart can be used to understand a complex

process in order to find the relationships and dependencies between events.

You can also get a brief idea about the critical path of the

process and the events involved in the critical path.

Flow

charts can be used for any field and to illustrate events involving processes

of any complexity. There are specific software tools developed for drawing flow

charts, such as MS Vision.

You will

be able to freely download some of the open source flow chart tools developed

by the open source community.

Applications:

In a product assembly how sub assemblies made and then build

into final product.

The time taken for before improvement is greater than after

improvement by using flow diagrams.

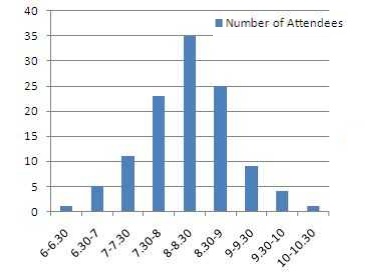

Histogram

Histogram is used for

illustrating the frequency and the extent in the context of two variables.

Histogram is a chart with columns. This represents the distribution by mean. If

the histogram is normal, the graph takes the shape of a bell curve.

If it is not normal, it may take

different shapes based on the condition of the distribution. Histogram can be

used to measure something against another thing. Always, it should be two

variables.

Consider

the following example: The following histogram shows morning attendance of a

class. The X-axis is the number of students and the Y-axis the time of the day.

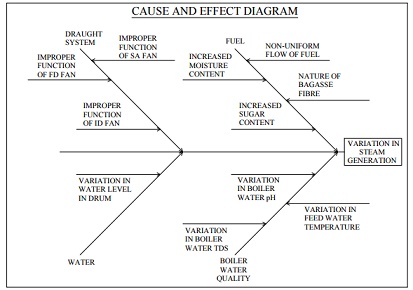

Cause and

Effect Diagram

Cause and effect diagrams

(Ishikawa Diagram) are used for understanding organizational or business problem

causes.

Organizations face problems

everyday and it is required to understand the causes of these problems in order

to solve them effectively. Cause and effect diagrams exercise is usually a

teamwork.

A

brainstorming session is required in order to come up with an effective cause

and effect diagram. All the main components of a problem area are listed and

possible causes from each area is listed. Then, most likely causes of the

problems are identified to carry out further analysis.

Check

Sheet

A check sheet can be introduced as the most basic tool for

quality. A check sheet is basically used for gathering and organizing data.

When this is done with the help of software packages such as

Microsoft Excel, you can derive further analysis graphs and automate through

macros available.

Therefore, it is always a good idea to use a software check

sheet for information gathering and organizing needs.

One can always use a paper-based check sheet when the

information gathered is only used for backup or storing purposes other than

further processing.

Types of

check sheet

1.

Process distribution check sheets.

2.

Defective item check sheets.

3.

Defect location check sheet.

4.

Defect factor check sheet.

Scatter Diagram

When it comes to the values of

two variables, scatter diagrams are the best way to present. Scatter diagrams

present the relationship between two variables and illustrate the results on a

Cartesian plane. Then, further analysis, such as trend analysis can be performed

on the values.

In these diagrams, one variable

denotes one axis and another variable denotes the other axis.

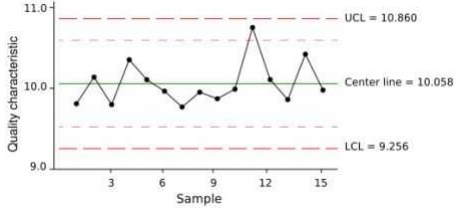

Control

Charts

Control chart is the best tool for monitoring the performance

of a process. These types of charts can be used for monitoring any processes

related to function of the organization.

These charts allow you to identify the following conditions

related to the process that has been monitored.

·

Stability of the process

·

Predictability of the process

·

Identification of common cause of variation

·

Special conditions where the monitoring party

needs to react

·

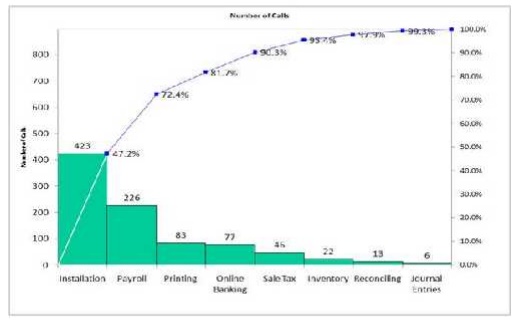

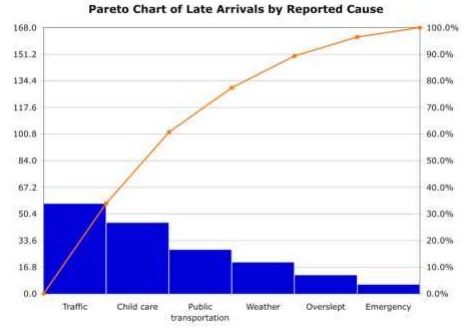

Pareto

Charts

Pareto charts are used for identifying a set of priorities.

You can chart any number of issues/variables related to a specific concern and

record the number of occurrences.

This way you can figure out the

parameters that have the highest impact on the specific concern. This helps you

to work on the propriety issues in order to get the condition under control.

SIGNIFICANCE:

Above

seven basic quality tools help you to address different concerns in an

organization.

Therefore, use of such tools should be a basic practice in the

organization in order to enhance the efficiency.

Trainings on these tools should be included in the

organizational orientation program, so all the staff members get to learn these

basic tools.

Most of the organizations use quality tools for various

purposes related to controlling and assuring quality.

Although there are a good number of quality tools specific to

certain domains, fields and practices, some of the quality tools can be used

across such domains. These quality tools are quite generic and can be applied

to any condition.

There are seven basic quality tools used in organizations. These

tools can provide much information about problems in the organization assisting

to derive solutions for the same.

A number of these quality tools come with a price tag. A brief

training, mostly a self-training, is sufficient for someone to start using the

tools.

Let's

have a look at the seven basic quality tools in brief.

Related Topics