Chapter: Mechanical : Total Quality Management (TQM) : Quality Management

Seven Steps to Strategic Quality Planning

STRATEGIC QUALITY PLANNING

Goals – Long term planning (Eg : Win the war)

Objectives – Short term planning (Eg : Capture the bridge)

Goals

should

Ø Improve

customer satisfaction, employee satisfaction and process

Ø Be based

on statistical evidence

Ø Be

measurable

Ø Have a

plan or method for its achievement

Ø Have a

time frame for achieving the goal

Ø Finally,

it should be challenging yet achievable

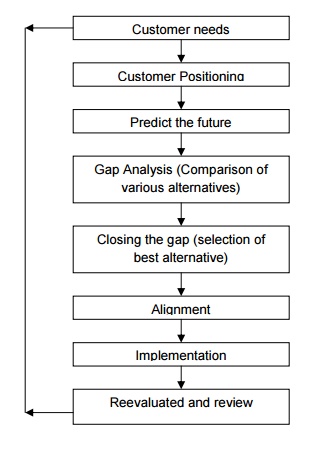

SEVEN

STEPS TO STRATEGIC QUALITY PLANNING

In order to integrate quality with the strategic planning

process, a systematic and sequential procedure has to be adopted. There are

seven basic steps to strategic process planning. They are

Step 1. Customer Needs

The basic step is the

identification of customers and their wants and needs. An organization must

seek its customers’ requirements, expectations and assess future trends before

developing a

strategic plan.

Step 2. Customer Position

The second step requires the

planners to determine its positioning with regards to its customers. Various

alternatives such as whether the organization should give up, maintain or

expand market position should be considered. In order to become successful, the

organization should concentrate and consolidate its position in its areas of

excellence.

Step 3. Predict the Future

Next, the planners must predict

future conditions that will affect their product or service: To help predicting

the future, the tools such as demographics, economic forecasts, and technical

assessments or projections may be used.

Step 4. Gap Analysis

In this step, the planners must

identify the gaps between the current state and the future state of the

organization. This concept is also known as value stream mapping.

For identifying the gaps, an analysis of the core values and concepts and other

techniques may be used.

Step 5. Closing the Gaps

Now the planners should develop a

specific plan to close the gaps. This process is also termed as Process

improvement. By assessing the relative importance and relative

difficulty of each gap, planners can close the gaps.

Step 6. Alignment

Now the revised plan should be aligned with the mission, vision, and core values and concepts of the organization. Organization should embrace quality as an essential ingredient in their vision, mission, and objectives.

Step 7. Implementation

In order to implement the action

plan, resources must be allocated to collecting data, designing changes, and

overcoming resistance to change. Also the planners should monitor and assess

the result of the strategic plan.

Since quality is a continuous

improvement process, one has to reassess and renew the strategic plans

periodically. So it is a cyclic process. Figure summarizes the strategic

planning cycle.

Related Topics