Chapter: Mechanical : Computer Aided Design : Fundamentals of Computer Graphics

Sequential and Concurrent Engineering

SEQUENTIAL AND CONCURRENT ENGINEERING

With today's marketplace becoming more and more competitive, there is an ever-increasing pressure on companies to respond quickly to market needs, be cost effective, reduce lead-times to market and deliver superior quality products.

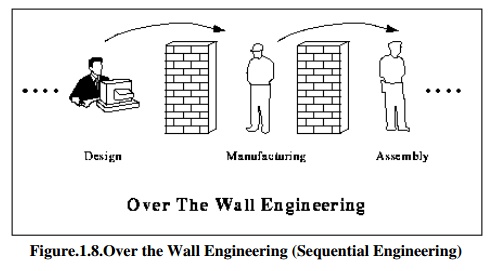

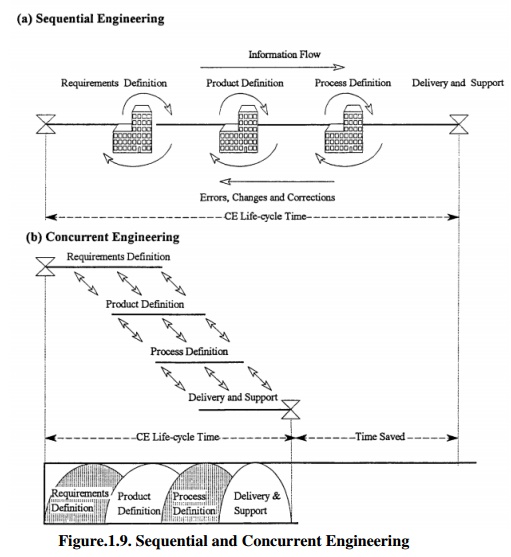

Traditionally, design has been carried out as a sequential set of activities with distinct non-overlapping phases. In such an approach, the life-cycle of a product starts with the identification of the need for that product. These needs are converted into product requirements which are passed on to the design department. The designers design the product's form, fit, and function to meet all the requirements, and pass on the design to the manufacturing department.

After the product is manufactured it goes through the phases of assembly, testing, and installation. This type of approach to life-cycle development is also known as `over the wall' approach, because the different life-cycle phases are hidden or isolated from each other. Each phase receives the output of the preceding phase as if the output had been thrown over the wall. In such an approach, the manufacturing department, for example, does not know what it will actually be manufacturing until the detailed design of the product is over.

Figure.1.8.Over the Wall Engineering (Sequential Engineering)

There are a lot of disadvantages of the sequential engineering process. The designers are responsible for creating a design that meets all the specified requirements. They are usually not concerned with how the product will be manufactured or assembled. Problems and inconsistencies in the designs are therefore, detected when the product reaches into the later phases of its life-cycle. At this stage, the only possible option is to send the product back for a re-design. The whole process becomes iterative and it not until after a lot of re-designs has taken place that the product is finally manufactured. Because of the large number of changes, and hence iterations, the product's introduction to market gets delayed. In addition, each re-design, re-work, re-assembly etc. incurs cost, and therefore the resulting product is costlier than what it was originally thought to be. The market share is lost because of the delay in product's introduction to market, and customer faith is lost. All this is undesirable.

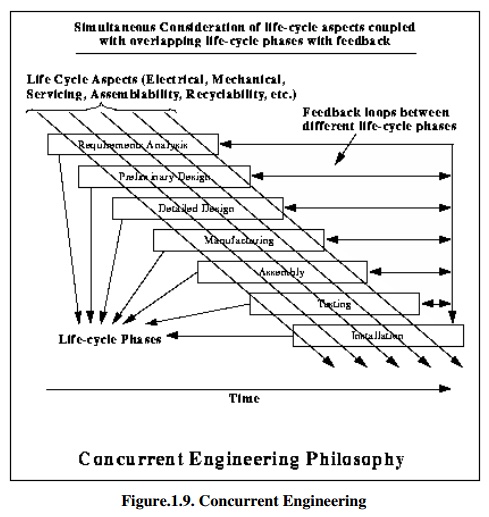

Concurrent Engineering is a dramatically different approach to product development in which various life-cycle aspects are considered simultaneously right from the early stages of design. These life-cycle aspects include product's functionality, manufacturability, testability, assimilability, maintainability, and everything else that could be affected by the design.

In addition, various life-cycle phases overlap each other, and there in no "wall" between these phases. The completion of a previous life-cycle phase is not a pre-requisite for the start of the next life-cycle phase. In addition, there is a continuous feedback between these life-cycle phases so that the conflicts are detected as soon as possible.

The concurrent approach results in less number of changes during the later phases of product life-cycle, because of the fact that the life-cycle aspects are being considered all through the design. The benefits achieved are reduced lead times to market, reduced cost, higher quality, greater customer satisfaction, increased market share etc. Sequential engineering is the term used to describe the method of production in a linear format. The different steps are done one after another, with all attention and resources focused on that one task. After it is completed it is left alone and everything is concentrated on the next task.

In concurrent engineering, different tasks are tackled at the same time, and not necessarily in the usual order. This means that info found out later in the process can be added to earlier parts, improving them, and also saving a lot of time. Concurrent engineering is a method by which several teams within an organization work simultaneously to develop new products and services and allows a more stream lined approach. The concurrent engineering is a non-linear product or project design approach during which all phases of manufacturing operate at the same time - simultaneously. Both product and process design run in parallel and occur in the same time frame.

Product and process are closely coordinated to achieve optimal matching of requirements for effective cost, quality, and delivery. Decision making involves full team participation and involvement. The team often consists of product design engineers, manufacturing engineers, marketing personnel, purchasing, finance, and suppliers.

Figure.1.9. Sequential and Concurrent Engineering

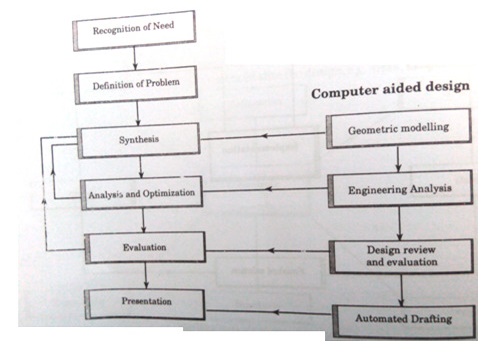

ROLE OF COMPUTERS IN DESIGN

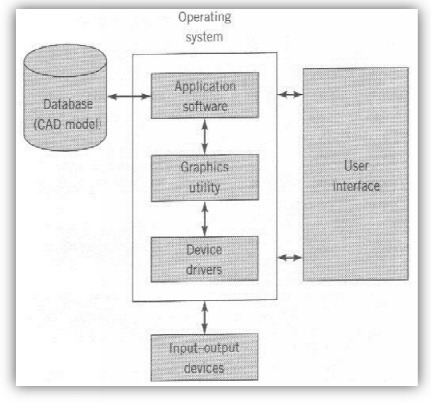

CAD SYSTEM ARCHIT ECTURE

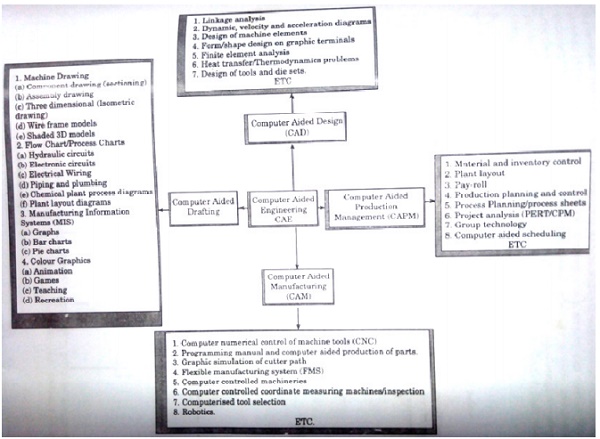

COMPUTER AIDED E NGINEERING – CAD/CAM

Related Topics