Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Industrial Robotics

Robot Programming

ROBOT

PROGRAMMING

To do

useful work, a robot must be programmed to perform its motion cycle. A robot program can be defined as a path in space 10 be followed by the

manipulator, combined with peripheral

actions that support the work cycle, Examples of the peripheral actions include

opening and closing the gripper, performing logical decision making, and

communicating with other pieces of equipment in the robot cell. A robot is

programmed by entering the

programming

commands into its controller memory. Different robots use different methods of

entering the commands

. In the

case of limited sequence robots, programming is accomplished by setting limit switches

and mechanical stops to control the endpoints of its motions. The sequence in

Lead through

Programming

Powered

Lead through Versus Manual Leadthrough. There are two methods of performing

the leadthrough teach procedure: (1) powered

leadthrough and (2) manual leadrhrough.

The

difference between the two is in the manner in which the manipulator is moved through the motion cycle

during programming. Powered leadthrough

is commonly used a~ thc programming method for playback robots with point-to-point

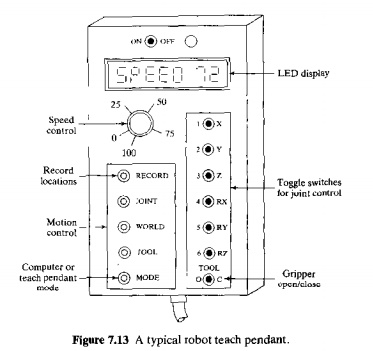

control. It in· valves the use of J teach pendant (handheld control box) that

has toggle switches and/or contact buttons for controlling the movement of the

manipulator joints. Figure 7.13 illustrates the important components of a teach

pendant. Using the toggle switches or buttons, the programmer power drives the

robot arm to the desired positions, in sequence, and records the positions into

memory. During subsequent playback, the robot moves through the sequence 01

positions under its own power.

Manual

leadthrough is convenient for programming playback robots with

continuous path control where the continuous path is an irregular motion pattern

such as in spray painting. This programming method requires the operator to

physically grasp the end-of-arm or tool attached to the arm and manually move

it through the motion sequence, recording the path into memory. Because the

robot arm itself may have significant mass and would therefore he difficult to

move, a special programming device often replaces the actual robot for the

teach procedure. The programming device has the same joint configuration as the

robot. and it is equipped with a trigger handle (or other control switch),

which is activated when the operator wishes to record motions into memory. The

motions arc recorded a~ a series of closely spaced points' During playback, the

path is recreated by controlling the actual robot arm through the same sequence

of points.

Motion

Programming. The lendthrough methods provide a very natural way

of

programming

motion commands into the robot controller. In manual leadthrough, the operator

simply moves the arm through the required path to create the program. In

powered leadthrough the operator uses a teach pendant to drive the manipulator.

The teach pen b equipped with switch or a pair of contact buttons for each

joint By activating these switches or in a coordinated fashion for the various

joints. the programmer moves the manipulator to The required positions in the

work space.

Coordinating

the individual joints with the teach pendant is sometimes an awkward way to

enter motion commands to the robot, For example, it is difficult to coordinate

the individual joints of a jointed-arm robot (TRR configuration) to drive the

end-of-arm in a straight line motion. Therefore, many of the robots using

powered leadthrough provide two alternative methods for controlling movement of

the manipulator during programming, in addition to individual joint controls.

With these methods, the programmer can control the robot's wrist end to move in

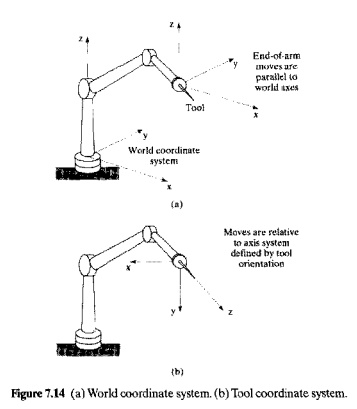

straight line paths. The names given to these alternatives are (1) world

coordinate system and (2) tool coordinate system. Both systems mak., use of a

Cartesian coordinate system. In/he world

coordinate system. the origin and frame of reference are defined with

respect to some fixed position and alignment relative to the robot base. This

arrangement is illustrated in Figure 7,14(a). In the tool coordinate system, shown in Figure 7 .14(b), the alignment of

the axis system is defined relative to the orientation of the wrist faceplate

(to which the end effector is attached). In this way, the programmer call

orient the tool in a desired way and then control the robot to make linear

moves in directions parallel OT perpendicular to the tool.

The world

coordinate system and the tool coordinate system are useful only if the robot

has the capacity to move its wrist end in a straight line motion, parallel to

one of the axes of the coordinate system. Straight line motion is quite natural

for a Cartesian coordinate robot (LOO configuration) but unnatural for robots

with any combination of rotational joints (types R, T, and V). To accomplish

straight line motion for manipulators with these types of joints requires a

linear interpolation process to be carried out by the robot's controller. In straight line interpolation. the control

computer calculates the sequence of addressable points in space that the wrist

end must move through to achieve a straight line path between two points.

There are

other types of interpolation that the robot can use. More common than straight

line interpolation is joint interpolation. When a robot is commanded to move

its wrist end between two points using joint

interpolation, it actuates each of the joints simultaneously at its own

constant speed such that all of the joints start and stop at the same time The

advantage of joint interpolation over straight line interpolation is that there

is usually less total motion energy required to make the move. This may mean

that the move could be made in slightly less time. It should be noted thai in

the case of a Cartesian coordinate robot, joint interpolation and straight line

interpolation result in the same motion path.

Still

another form of interpolation is that used in manual leadthrough programming In

this case, the robot must follow the sequence of closely space points that are

defined during the programming procedure. In effect, This is an interpolation

process for a path that usually consists of irregular smooth motions.

The speed

of the robot is controlled by means of a dial or other input device, located on

the teach pendant and/or tile main control panel. Certain motions in the work

cycle should be performed at high speeds (e.g., moving parts over substantial

distances in the work (ell), while other motions require low speed operation

(e.g. motions that require high precision in placing the workpart). Speed

control also permits a given program to be tried out at a safe slow speed and

then at a higher speed to be used during production.

There are

several inherent disadvantages of the lcadthrough programming methods. First,

regular production must he interrupted during the leadthrough programming

procedures. In other words, leadthrough programming results in downtime of the

robot cell or production line. The economic consequence of this is that the

lead through methods must be used for relatively long production runs and are

inappropriate for small batch sizes

Second.

the teach pendant used with powered leadthrough and the programming devices

used with manual leadthrough arc limited in terms of the decision-making logic

that can he incorporated into the program. It is much easier to write logical

instructions using the computer like robot languages than the lead through

methods

Third,

since the leadthrough methods were developed before computer control became

common for robots, these methods are not readily compatible with modem computer-based

technologies such as CAD/CAM, manufacturing data bases, and local

communications networks. The capability to readily interface the various

computer-automated subsystems in the factory for transfer of data is considered

a requirement for achieving computer integrated manufacturing.

Robot Programming languages

The use of

textual programming languages became an appropriate programming method as

digital computers took over the control function in robotics. Their use has

been stimulated by the increasing complexity of the tasks that robots are

called on to perform, with the concomitant need to imbed logical decisions into

the robot work cycle. These computer-like programming languages are really-online/off-fine

methods of programming, because the robot must still be taught its locations

using the leadthrough method. Textual programming languages for robots provide

the opportunity to perform the following functions that Ieadthrough programming

cannot readily accomplish:

enhanced

sensor capabilities. including the use of analog as well as digital inputs and

outputs

improved output

capabilities for controlling external

equipment

program logic that is beyond the capabilities of leadthrough methods

computations and data processing similar

to computer programming languages

communications with other

computer systems

This

section reviews some of the capabilities of the current generation robot

program ming languages. Many of the language statements are taken from actual

robot programming languages.

Motion

Programming. Motion programming with robot languages usually

requires a combination of textual statements and leadthrough techniques.

Accordingly, this method of programming is sometimes referred to as online/offline programming. The

MOVE PI

which

commands the robot to move from its current position to a position and

orientation defined by the variable name Pl. The point P1 must be defined, and

the most convenient way to define P1 is to use either powered leadthrough or

manual leadthrough to place the robot at the desired point and record that

point into memory. Statements such as

HERE PI

or

LEARN PI

are used

in the lcadthrough procedure to indicate the variable name for the point. What

is recorded into the robot's control memory is the set of joint positions or

coordinates used by the controller to define the point. For example, the

aggregate

(236.158,65.0.0,O)

could be

utilized to represent the joint positions for a six-jointed manipulator. The

first three values (236.158.65) give the joint positions of the body-and-arm,

and the last three values (0,0.0) define the wrist joint positions. The values

are specified in millimeters or degrees. Depending on the joint types.

There are

variants of the MOVE statement. These include the definition of straight line

interpolation motions, incremental moves, approach and depart moves, and paths.

For example, the statement

MOVES PI

denotes a

move that is to be made using straight line interpolation, The suffix S on MOVE

designates straight line motion.

An

incremental move is one whose endpoint is defined relative to the current

position of the manipulator rather than to the absolute coordinate system of

the robot. For example, suppose the robot is presently at a point defined by the

joint coordinates (236, 158, 65,0,O,0),and it is desired to move joint 4

(corresponding to a twisting motion of the wrist) from 0 to 125,The following

form of statement might be used to accomplish this move'

DMOVE (4, 125)

The new

joint coordinates of the robot would therefore be given by (236, 158, 65, 125, 0,

0). The prefix D is interpreted as delta, so DMOVE represents a delta move, or

incremental move.

Approach

and depart statements are useful in material handling operations. The APPROACH

statement moves the gripper from its current position 10 within a certain

distance

of the pickup

(or drop-off) point, and then a MOVE statement is used to position the end

effector at the pickup point. After the pickup is made. a DEPART statement IS

used to move the gripper away from the point. The following statements

illustrate the sequence:

APPROACH

P1,40 MM

MOVE PI

(actuate

gripper)

DEPART 40

MM

The final

destination is point Pl. but the APPROACH command moves the gripper to a safe

distance (40 mm) above the point. This might be useful to avoid obstacles such

as other parts in a tote pan. The orientation of the gripper at the end of the

APPROACH move is the same as that defined for the point PI, so that the final

MOVE Pi is really a spatial translation of the gripper. This permits the

gripper to be moved directly to the part

for

grasping.

A path in

a robot program is a series of points connected together in a single move. The

path is given a variable name, as illustrated in the following statement:

DEFINE PATHl23 = PATH(Pl.P2,P3)

This is a

path that consists of points PI. P2, and P3. The points are defined in the

manner described above. A MOVE statement is used to drive the robot

through the path.

MOVE PA.TH123

The speed

of the robot is controlled by defining either a relative velocity or an

absolute velocity. The following statement represents the case of relative

velocity definition:

SPEED 75

when this

statement appears within the pr ograrn, it is typically interpreted to mean

that the manipulator should operate at 75% of the initially commanded velocity

in the statements that follow in the program. The initial speed is given in a

command that precedes the execution of the robot program, For example,

SPEEDO.5MPS

EXECUTE PROGRAMI

indicates

that the program named PROGRAM} is to be executed by the robot, and rhar the

commanded speed during execution should he 0.5 m/sec.

Interlock

and Sensor Commands. The two basic interlock commands (Section 4.3.2)

used for industrial robots are WAIT and SIGNAL. The WAIT command is used to

implement an input interlock. For example,

WAIT20,ON

would

cause program execution to stop at this statement until the input signal coming

into the robot controller at port 20 was in an "on" condition. This

might be used to cause the robot to want for the completion of an automatic

machine cycle in a loading and unloading application.

The

SIGNAL statement is used to

implement an output interlock. This is used to communicate to some external piece of equipment. For example,

SIGNAL 10. ON

would

switch on the signal at output port 10, perhaps to actuate the start of an

automatic machine cycle.

Both of

the above examples indicate on/off signals. Some robot controllers possess the

capacity to control analog device, that operate at various levels. Suppose it

were desired to turn on an external device that operates on variable voltages

in the range 0 to 10 V. The command

SIGNAL 10,6.0

is

typical of a control statement that might be used to output a voltage level of 6.0

V to the device from controller output port 10.

All of

the above interlock commands represent situations where the execution of the

statement occurs at the point in the program where the statement appears. There

are other situations in which it is desirable for an external device to be

continuously monitored for any change that might occur in the device, This

might be useful, for example, in safety monitoring where a sensor is set up to

detect the presence of humans who might wander into the robot's work volume.

The sensor reacts to the presence of the humans by signaling the robot controller. The following type of statement might

he used for this case:

REACT 25. SAFESTOP

This

command would be written to continuously monitor input port 25 for any changes

in the incoming signal. If aud when a change in the signal occurs, regular

program execution is interrupted, and control is transferred to a subroutine

called SAFESTOP. This subroutine would stop the robot from further motion

and/or cause some other safety action to be taken.

End effectors

arc devices that, although they are attached to the wrist of the manipulator.

are actuated very much like external devices. Special commands are usually

written for controlling the end effector. In the case of grippers, the basic

commands are

OPEN

and

CLOSE

which

came the gripper to actuate to fully open and fully closed positions,

respectively. Greater control over the gripper is available in some sensored

and servo-controlled hands.

For

grippers that have force sensors that can be regulated through the robot

controller, a command such as

CLOSE2.0N

controls

the dosing of the gripper until a 2.0N force is encountered by the gripper fingers. A similar

command used \0 close the gripper to a given opening width is:

CLOSE25MM

A special

set of statements is often required to control the operation of tool-type end

effectors, such as spot welding guns, arc welding tools, spray painting guns,

and powered spindles (for drilling, grinding, etc.]. Spot welding and spray

painting controls are typically simple binary commands (e.g., open/close and

on/off), and these commands would be similar to those used for gripper control.

In the case of arc welding and powered spindles, a greater variety of control

statements is needed to control feed rates and other parameters of the

operation

Computations

and Program Logic. Many of the current generation robot languages

possess capabilities for performing computations and data processing operations

that are similar to computer programming languages. Most present-day robot

applications do not require a high level of computational power. As the

complexity of robot applications grows in the future, it is expected that these

capabilities will be better utilized than at present,

Many of

today's applications of robots require the use of branches and subroutines in

the program. Statements such as

GOTO 150

and

IF

(logical expression) GO TO 150

cause

tile program TO branch to some other statement in the program [e.g., to

statement number 150 in the above illustrations).

A

subroutine in a robot program is a group of statements that are to be executed

separately when called from the main program. In a preceding example, the

subroutine SAFESTOP was named in the REACT statement for use in safety

monitoring. Other uses of subroutines include mak.ing calculations or

performing repetitive motion sequences at a number of different places in the

program. Rather than write the same steps several times in the program, The use

of a subroutine is more efficient.

Simulation and Offline

Programming

The

trouble with leadthrough methods and textual programming techniques is that the

robot must be ta.ken out of production for a certain length of time to

accomplish the programming. Off-line programming permits the robot program to be prepared at a remote computer

terminal and downloaded to the robot controller for execution. In true offline programming.

there is no need to physically locate the positions in the workspace for the

robot as required with present textual programming languages. Some form of

graphical computer simulation is required to validate the programs developed

offline, similar to offline procedures used in NC part programming. The

advantage of true offline programming is that new programs can be prepared and

downloaded to the robot without interrupting production

The off-line

programming procedures being developed and commercially offered use graphical

simulation to construct a three-dimensional model of a robot cell for

evaluation and offline programming. The cell might consist of the robot,

machine tools, conveyors, and other hardware. The simulator permits these cell

components to be displayed on the graphic, monitor and for the robot to perform

its work cycle in animated computer graphics. After the program has been

developed using the simulation procedure, it is then converted into the textual

Language corresponding to the particular robot employed in the cell. This is a

step in the offline programming procedure that is equivalent to post-processing

in NC part programming.

In the

current commercial offline programming packages, some adjustment must be

performed to account for geometric differences between the three-dimensional

model in the computer system and the actual physical cell. For example, the

position of a machine tool in the physical layout might be slightly different

than in the model used to do the off-line programming. For the robot to

reliably load and unload the machine, it must have an accurate location of the

load/unload point recorded in its control memory. This module is used to

calibrate the 3D computer model by substituting location data from the actual

cell for the approximate values developed in the original model. The

disadvantage with calibrating the cell is that time is lost in performing this

procedure.

In future

programming systems, the offline procedure described above will probably be

augmented hy means of machine vision and other sensors located in the cell. The

vision and sensor systems would be used to update the three-dimensional model

of the workplace and thus avoid the necessity for the calibration step in

current offline programming methods. The term sometimes used 10 describe these

future programming systems in which the robot possesses accurate knowledge of

its three-dimensional workplace is world

modeling. Associated with. the concept of world modeling is the use of very

high-level language statements, in

which the programmer specifies a task to be done without giving details of the

procedure used to perform the tusk. Examples of this type of statement might be

ASSEMBLE PRINTING MECHANISM TO BRACKET

or

WELD UPPER PLATE TO LOWER PLATE

The

statements are void of any reference to points in space or motion paths to be

followed by the robot. Instead, the three-dimensional model residing in the

robot's control memory would identify the locations of the various items to be

assembled or welded. The future robot would possess sufficient intelligence to

figure out its own sequence of motions and actions for performing the task

indicated.

Related Topics