Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Regenerative Ranking Cycle and Binary Vapour Cycle

Regenerative

Ranking Cycle and Binary Vapour Cycle

The

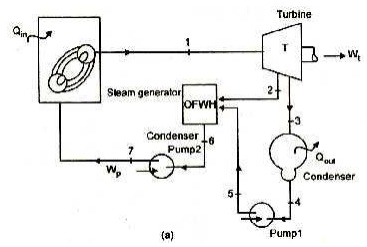

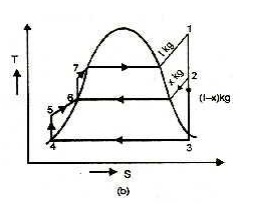

regenerative Ranking cycle is so named because after emerging from the

condenser (possibly as a sub cooled liquid) the working fluid heated by steam

tapped from the hot portion of the cycle and fed in to Open Feed Water

Heater(OFWH). This increases the average temperature of heat addition which in

turn increases the thermodynamics efficiency of the cycle.

Figure

Binary

Vapour Cycle

Generally water is used a working fluid in vapour power

cycle as it is found to be better than any other fluid, but it is far from

being the ideal one. The binary cycle is an attempt to overcome some of the

shortcomings of water and to approach the ideal working fluid by using two

fluids. The most important desirable characteristics of the working fluid

suitable for vapour cycles are:

a .A high

critical temperature and a safe maximum pressure.

b. Low- triple point temperature

c. Condenser pressure is not too low.

d.high enthalpy of vaporization

e. High thermal conductivity

f. It must be readily available,

inexpensive, inert and non-toxic.

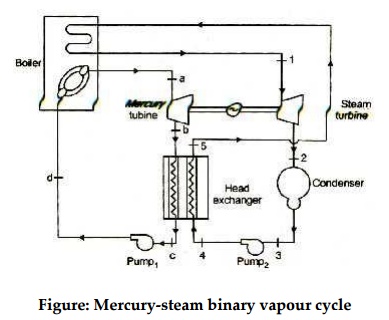

Figure:

Mercury-steam binary vapour cycle

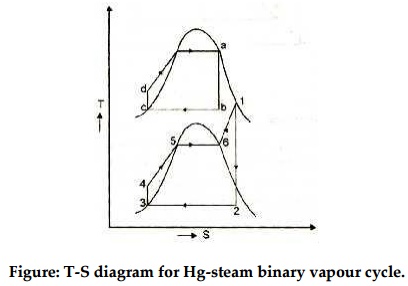

Figure: T-S diagram for Hg-steam

binary vapour cycle.

Therefore it can be concluded that no single working

fluids may have desirable requirements of working fluid. Different working

fluids may have different attractive feature in them, but not all. In such

cases two vapour cycles operating on two different working fluids are put

together, one is high temperature region and the other in low temperature

region and the arrangement is called binary vapour cycle.

The layout of mercury-steam binary vapour cycle is shown

in figure. Along with the depiction of T-S diagram figure. Since mercury having

high critical temperature (898°C) and low critical pressure (180

bar) which makes a suitable working fluid will act as high temperature cycle

(toppling cycle) and steam cycle will act as low temperature cycle.

Here mercury vapour are generated in mercury boiler and

sent for expansion in mercury turbine and expanded fluid leaves turbine to

condenser. In condenser, the water is used for extracting heat from the mercury

so as to condensate it. The amount water entering mercury condenser. The

mercury condenser also act as steam boiler for super heating of heat liberated

during condensation of mercury is too large to evaporate the water entering of

seam an auxiliary boiler may be employed or superheating may be realized in the

mercury boiler itself. From the cycle,

Since

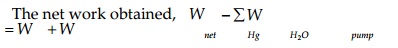

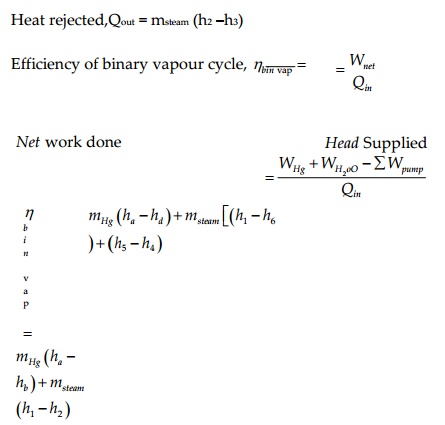

pump works are very small, it may be neglected. Work from Mercury Turbine, WHg

=mg (ha -hb )

Work from Steam Turbine, Wsteam =msteam (h1 -h2 )

Pump work, Wpump =mHg (hd -hc )+msteam (h4 -h3 )

Heat

supplied to the cycle, Qin =mHg (ha -hd )+msteam éë(h1 -h6 )+(h5 -h4 ) Heat rejected,Qout = msteam (h2 –h3)

Related Topics