Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Signalling and Interlocking

Railway Interlocking

Interlocking

Interlocking is a device or a

system meant to ensure the safety of trains. With the increase in the number of

points and the signals and introduction of high speeds, it has become necessary

to eliminate human error, which would otherwise lead to massive losses of life

and property. The points and signals are set in such a way that the cabin man

cannot lower the signal for the reception of a train unless the corresponding

points have been set and locked. The signal is thus interlocked with the points

in a way that no conflicting movement is possible and the safety of trains is

ensured.

Interlocking can, therefore, be

defined as an arrangement of signals, points, and other apparatus so

interconnected by means of mechanical or electrical locking that they can be

operated in a predetermined sequence to ensure that there is no conflicting

movement of signals and points and trains run safely.

The signal and interlocking

system is so designed that the failure of any equipment results in the turning

on of the signal, thus ensuring train safety.

1 Essentials

Lever frames and other apparatus

provided for the operation and control of signals, points, etc., must be so

interlocked and arranged as to comply with the following essential regulations.

(a) It should

not be possible to turn a signal off unless all points for the line on which

the train is to be received are correctly set, all the facing points are

locked, and all interlocked level crossings are closed and inaccessible to road

traffic.

(b) The line

should be fully isolated before the signal is turned off, i.e., no loose wagons

should be able to enter this line.

(c) After the

signal has been turned off, it should not be possible to make adjustments in

the points or locks on the route, including those in the isolated line. Also,

no interlocked gates should be released until the signal is replaced in the

'on' position.

(d) It should

not be possible to turn any two signals off at the same time, as this can lead

to conflicting movements of the trains.

(e) Wherever

feasible, the points should be so interlocked as to avoid any conflicting movement.

2 Standards

The speed of a train depends on a

number of factors such as the haulage capacity of the locomotive, the fitness

of the track, the fitness of the rolling stock, the load of the train, etc.,

and the speed for a particular section is determined based on all these

factors. Depending upon the maximum speeds permitted in a section, the stations

are interlocked in keeping with the prevalent standards, and signalling

equipment and other facilities are provided accordingly. There are four standards

of interlocking based on the maximum permissible speeds prevailing on Indian

Railways. These refer to the speeds over the main line with respect to the

facing points and the yard.

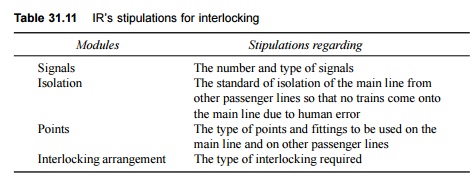

Table 31.11 lists the

stipulations laid down by Indian Railways for signals, isolation, points, and

interlocking arrangements. The details of each of these interlocking standards

are enumerated in Table 31.12.

Table 31.11 IR's stipulations for

interlocking

3 Methods

There are basically two methods of interlocking as explained

below.

Key interlocking

Key interlocking is the simplest

method of interlocking and still exists on branch lines of small stations on

Indian Railways. The method involves the manipulation of keys in one form or

the other. This type of interlocking is normally provided with standard I

interlocking with a speed limit below 50 km/h. The simplest arrangement of key

interlocking is accomplished in the following manner.

(a) Take the

example of a station with a main line and a branch line. The point can be set

either for the main line or branch line.

(b) The point

has two keys. The first is key A, which can be taken out when the point is set

and locked for the main line. Similarly, key B can be taken out when the point

is set and locked for the loop line. At any given time either key A or key B

can be taken out, depending upon whether the route is set for the main line or

the loop line.

(c) The lever

frame operating the signals is provided with two levers. The lever concerning

the main line signal can be operated only by key A and similarly the branch

line signal lever can be operated only by key B.

(d) If the

train is to be received on the main line, the points are set and locked for the

main line and key A is released. This key is used for unlocking the main line

signal lever, thus lowering the signal for the main line. Since key A cannot be

used for interlocking and lowering the branch line signal, only the appropriate

signal can be turned off. This type of interlocking is called

indirect

locking.

In case more than one point is to

be operated, the key released at the first point is used to unlock and operate

the second point and so on. The key released at the last point can then be used

for unlocking the lever operating the appropriate signal. This type of

interlocking is also known as succession locking and is also used for

checking conflicting movements in shunting operations. There are other methods

of interlocking with the help of keys, but all of them involve considerably

lengthy trips from the point to the signal levers and from point to point,

thereby leading to delays. Such arrangements are, therefore, satisfactory only

for stations that handle very light traffic.

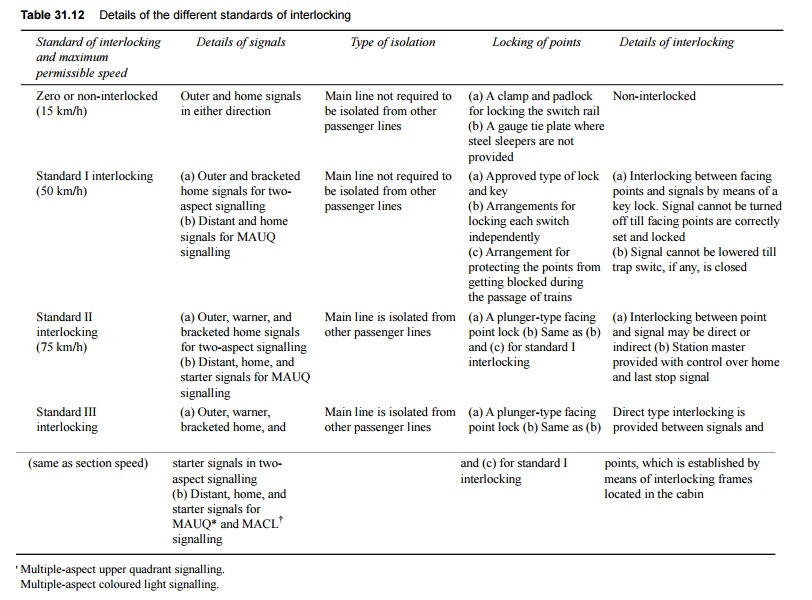

Table 31.12 Details of the different

standards of interlocking

Mechanical interlocking

Mechanical interlocking or

interlocking on lever frames is an improved form of interlocking compared to

key locking. It provides greater safety and requires less manpower for its

operation. This method of interlocking is done using plungers and tie bars. The

plungers are generally made of steel sections measuring 30 cm × 1.6 cm and have

notches in them. The tie bars are placed at right angles to the plungers and

are provided with suitably shaped and riveted pieces of cast iron or steel that

fit exactly in the notches of the tappets.

The main components of an

interlocking system are a locking frame, point fittings, signal fittings, and

connecting devices for connecting the locking frame to the point and signal

fittings. The locking frame consists of a number of levers, which work various

points, point locks, signal levers, etc. The levers are arranged together in a

row in a frame. Pulling a point lever operates the point to which it is

connected through a steel rod. Similarly, pulling a signal lever changes the

indication of the signal by pulling the wire connecting the lever and the

signal. To each lever is attached a plunger which has suitably shaped notches

to accommodate the locking tappets. The entire arrangement is provided in a

locking trough where tappets are provided, which move at right angles to the

plungers.

When a lever is pulled, it causes

the plunger to which it is connected to move. Due to wedge action, the

tappet accommodated in the notch of the plunger is pushed out at right angles

to the movement of the plunger. The motion is transmitted to all other tappets

that are connected to this tappet through a tie bar. As a result of this

motion, the other tappets either get pushed into or out of the respective notches

of the other plunger depending upon the type of interlocking provided. In case

the other tappet is free but slips inside the notch of the other plunger, it

locks the lever connected to this plunger. In consequence, the other lever gets

locked in that position and cannot be operated. However, if the tappet was

earlier positioned in the notch of the plunger, thereby locking the lever, and

is now out of the notch, the other lever becomes free to be operated.

4 Different Cases

The following cases of interlocking are encountered in

practical application.

Normal locking In this

case, pulling one lever locks the other lever in its normal position.

Back locking or release locking In this

case, when the lever is in its normal position, it also blocks the other

lever in its normal position, but when this lever is pulled it releases the

other lever, which can then also be pulled. Furthermore, once the second lever

is also pulled, the first lever gets locked in the 'pulled' position and cannot

be returned to its normal position unless the second lever is restored to its

normal position.

Both wall locking In this

case, once a lever is pulled, it locks the other lever in its current

position, i.e., in the normal or pulled position.

Special or conditional locking In this

case, the pulling of one lever locks the other lever only when certain

conditions are fulfilled, say the third lever being in a normal or pulled

position as the case may be.

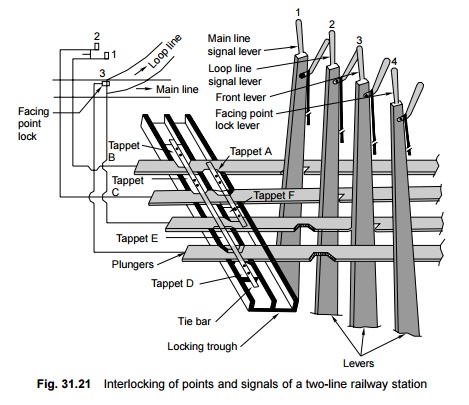

5 Mechanical Interlocking of Points and

Signals of a Two-line Railway Station

To understand the mechanical

interlocking of the points and signals of a two-line railway station, let us

take the case of a typical railway station that has both a main line and a loop

line. It is provided with a home signal 1 operated by lever 1 for the main line

and a home signal 2 operated by lever 2. Point 3 is set for the main line when

lever 3 is in its normal position and for the loop line when lever 3 is pulled.

In its pulled position lever 4 locks point 3 in either position (normal or reverse)

by pushing the plunger of the facing point into the 'lock in' position. The

essentials of this interlocking system are as follows (Fig. 31.21).

(a) It should

not be possible to turn off both the signals, i.e., 1 and 2 at the same time,

i.e., the train should be received either on the main line or the loop line at

any given time. To achieve this, tappet A is forced out of the plunger of lever

1 when lever 1 is pulled. The tappet enters the notch of the plunger of lever 2

and cannot move out until lever 1 is pulled. This prevents lever 2 from getting

pulled when lever 1 is pulled. The reverse of this situation is also true.

(b) It should

not be possible to turn a signal off until and unless the point is set and

locked. If an effort is made to pull either lever 1 or 2, the same cannot be

pulled. This is because of the following reasons. Tappets B and C are rivetted

with a tie bar that is in turn connected with tappet D. Since tappet D is

butting against the face of the plunger of lever 4, tappet B or C cannot be

moved. This plunger can move only when lever 4 is pulled, thereby bringing the

notch of the plunger opposite tappet D. Once this happens, it is not possible

to restore the position of lever 4 till lever 1 or 2 has been brought back to

its normal position. This is a case of release locking. Levers 1 and 2

are released by pulling lever 4, which in turn locks the point.

(c) Lever 4

is a lock lever and locks point 3 in either position. The same can be

visualized for tappet E.

(d) Similarly,

the main line home signal lever 1 cannot be pulled if point lever 3 is pulled,

i.e., if it is set for the loop line, as the tappet F cannot be pushed, which

allows lever 1 to be pulled when the notch in the plunger of lever 3 that lies

opposite tappet F has been shifted from its position due to the pulling of

lever 3. With lever 3 normal, lever 1 can be pulled conveniently,

simultaneously resulting in the locking of lever 2 in it normal position by

tappet A.

This example indicates that, with

proper planning, it is possible to mechanically interlock the movement of

points and signals and thus ensure complete safety.

6

Electrical Interlocking of Points

and Signals of a Two-line Railway Station

Electrical interlocking is

achieved through electric switches known as relays. The manipulation of relays

achieves interlocking, whereas lever locks that are attached with the levers in

place of plungers or in addition to plungers prevent a lever from getting

pulled, or allow it to get pulled or normalized if the interlocking so permits.

Relays use the simple principle

of electromagnetism, whereby a soft iron core wrapped inside a wire coil turns

into electromagnet when current is passed through the wire. An armature is

attached to this electromagnet, which has a number of finger contacts that come

into contact with each other when the armature is attracted to the magnet and

break the contact when the armature is not attracted to it. The whole system is

housed in a glass or metal box and is known as relay.

Related Topics