Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Points and Crossings

Railway Engineering: Crossing

Crossing

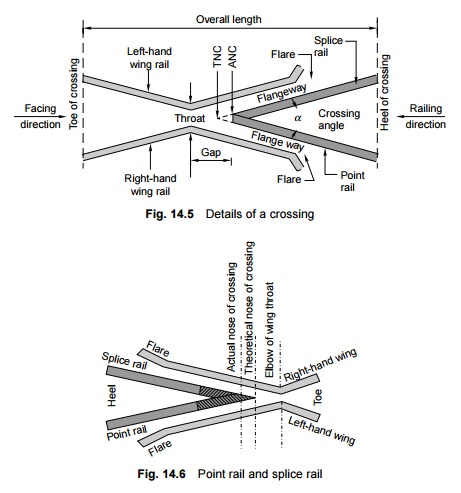

A crossing or frog is a

device introduced at the point where two gauge faces cross each other to permit

the flanges of a railway vehicle to pass from one track to another (Fig. 14.5).

To achieve this objective, a gap is provided from the throw to the nose of the

crossing, over which the flanged wheel glides or jumps. In order to ensure that

this flanged wheel negotiates the gap properly and does not strike the nose,

the other wheel is guided with the help of check rails. A crossing consists of

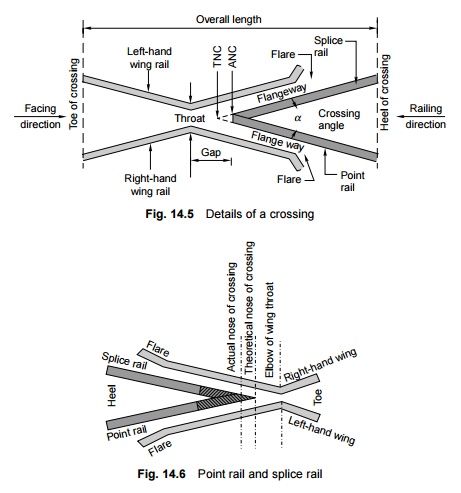

the following components, shown in Fig. 14.6.

(a) Two

rails, the point rail and splice rail, which are machined to form

a nose. The point rail ends at the nose, whereas the splice rail joins it a

little behind the nose. Theoretically, the points rail should end in a point

and be made as thin as possible, but such a knife edge of the point rail would

break off under the movement of traffic. The point rail, therefore, has its

fine end slightly cut off to form a blunt nose, with a thickness of 6 mm

(1/4"). The toe of the blunt nose is called the actual nose of crossing

(ANC) and the theoretical point where gauge faces from both sides intersect is

called the theoretical nose of crossing (TNC). The 'V' rail is planed to

a depth of 6 mm (1/4") at the nose and runs out in 89 mm to stop a

wheel running in the facing direction from hitting the nose.

(b) Two wing

rails consisting of a right-hand and a left-hand wing rail that converge to

form a throat and diverge again on either side of the nose. Wing rails are

flared at the ends to facilitate the entry and exit of the flanged wheel in the

gap.

(c) A pair of

check rails to guide the wheel flanges and provide a path for them, thereby

preventing them from moving sideways, which would otherwise may result in the

wheel hitting the nose of the crossing as it moves in the facing direction.

1 Types of Crossings

A crossing may be of the following types.

(a) An acute

angle crossing or 'V' crossing in which the intersection of the two gauge

faces forms an acute angle. For example, when a right rail crosses a left rail,

it makes an acute crossing. Thus, unlike rail crossings form an acute crossing

(A and C of Fig. 15.9).

(b) An obtuse

or diamond crossing in which the two gauge faces meet at an obtuse

angle. When a right or left rail crosses a similar rail, it makes an obtuse

crossing (B and D of Fig. 15.9).

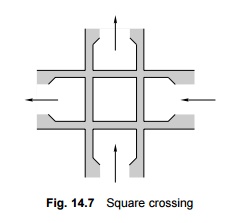

A square

crossing in which two tracks cross at right angles. Such crossings are

rarely used in actual practice (Fig. 14.7).

For

manufacturing purposes, crossings can also be classified as follows.

Built up crossing In a

built-up crossing, two wing rails and a V section consisting of splice

and point rails are assembled together by means of bolts and distance blocks to

form a crossing. This type of crossing is commonly used on Indian Railways.

Such crossings have the advantage that their initial cost is low and that

repairs can be carried out simply by welding or replacing each constituent

separately. A crossing becomes unserviceable when wear is more than 10 mm

(3/8"). A built-up crossing, however, lacks rigidity. The bolts require

frequent checking and sometimes break under fast and heavy traffic.

Cast steel crossing This is a

one-piece crossing with no bolts and, therefore, requiring very little

maintenance. Comparatively, it is a more rigid crossing since it consists of

one complete mass. The initial cost of such a crossing is, however, quite high

and its repair and maintenance pose a number of problems. Recently cast

manganese steel (CMS) crossings, which have longer life, have also been

adopted.

Combined

rail and cast crossing This is a combination of a built-up and cast

steel crossing and consists of a cast steel nose finished to ordinary rail

faces to form the two legs of the crossing. Though it allows the welding of

worn out wing rails, the nose is still liable to fracture suddenly.

2 CMS Crossing

Due to increase in traffic and

the use of heavier axle loads, the ordinary built-up crossings manufactured

from medium-manganese rails are subjected to very heavy wear and tear,

specially in fast lines and suburban sections with electric traction. Past

experience has shown that the life of such crossings varies from 6 months to 2

years, depending on their location and the service conditions. CMS crossings

possess higher strength, offer more resistance to wear, and consequently have a

longer life. The following are the main advantages of CMS crossings.

(a) Less wear

and tear.

(b) Longer

life: The average life of a CMS crossing is about four times more than that of

an ordinary built-up crossing.

(c) CMS

crossings are free from bolts as well as other components that normally tend to

get loose as a result of the movement of traffic.

These days CMS crossings are

preferred on Indian Railways. Though their initial cost is high, their

maintenance cost is relatively less and they last longer. However, special care

must be taken in their laying and maintenance. Keeping this in view, CMS crossings

have been standardized on Indian Railways. On account of the limited

availability of CMS crossings in the country, their use has, however, been

restricted for the time being to group A routes and those lines of other routes

on which traffic density is over 20 GMT. These should also be reserved for use

on heavily worked lines of all the groups in busy yards.

3 Spring or Movable Crossing

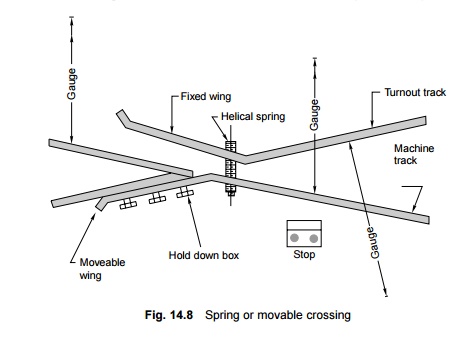

In a

spring crossing, one wing rail is movable and is held against the V of the

crossing with a strong helical spring while the other wing rail is fixed (Fig.

14.8). When a vehicle passes on the main track, the movable wing rail is snug

with the

crossing and the vehicle does not

need to negotiate any gap at the crossing. In case the vehicle has to pass over

a turnout track, the movable wing is forced out by the wheel flanges and the

vehicle has to negotiate a gap as in a normal turnout.

This type of crossing is useful

when there is high-speed traffic on the main track and slow-speed traffic on

the turnout track.

4 Raised Check Rails for Obtuse Crossings

In order to provide a guided

pathway in the throat portion of a 1 in 8.5 BG obtuse diamond crossing, the

check rails are raised by welding a 25-mm-thick MS plate. This arrangement is

considered satisfactory for BG as well as MG routes.

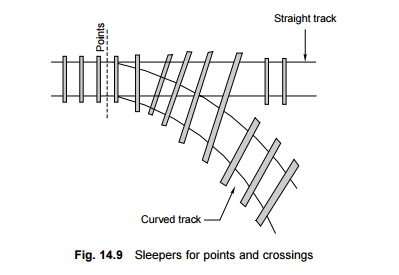

5 Position of Sleepers at Points and

Crossings

Sleepers

are normally perpendicular to the track. At points and crossings, a situation

arises where the sleepers have to cater to the main line as well as to the

turnout portion of the track. For this purpose, longer sleepers are used for

some length of the track as shown in Fig. 14.9.

Related Topics