Textiles and Dress Designing - Process Flow in a Garment Industry | 12th Textiles and Dress Designing : Chapter 12 : Apparel Merchandising

Chapter: 12th Textiles and Dress Designing : Chapter 12 : Apparel Merchandising

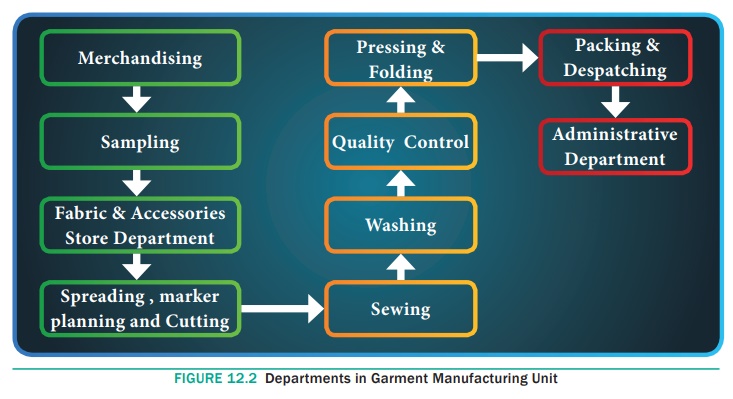

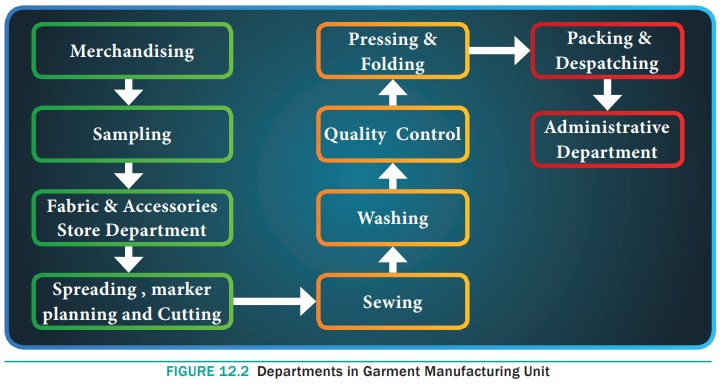

Process Flow in a Garment Industry

Process Flow in a Garment Industry

Garment manufacturing includes a number of processes from order

receiving to dispatching and shipment of the finished garments.

Merchandising Department

Merchandiser is a person who interacts with the buyer and seller,

and also puts efforts into proper relation between buying offices, buying agents,

agency and seller, exporter in terms of executing an order. A garment export

unit generally has many departments like stores, cutting, production, packing

and checking. Merchandising department is the star of the department among all

the working departments in the export concern, because merchandising is the

only department having maximum control over the departments and totally

responsible for profit and loss of the company. The job of a merchandiser is to

coordinate with the entire department in the office as well as the customers.

Merchandiser meets the buyers and collects the details of their requirements to

develop the relationship with the customer. After conformation of an order from

the buyer the planning process for execution of the order is done.

Sampling

Designing and sampling are the main process in garment industry

and it has a vital role in attracting buyers. The buyers generally places the

order after they are satisfied with the quality of the samples. The samples

decide the ability of an exporter. The buyer will access the exporter and his

organisation only by the samples. The purpose of sampling is not only to get

bulk orders and also give some additional benefits to the exporters. By doing

sampling the exporter can estimate the yarn consumption for developing the

fabric, a clear idea on costing and more over the manufacturing difficulties.

There are different phases of sampling; the first phase covers the development

of the initial concept or design idea through its approval by the customer. The

second phase covers the process following acceptance of the first prototype

sample and includes the functions of sourcing and ordering component, testing

the product and carry out trails and finalized sample specifications. The third

and final phase includes a range of activities that are carried out before

large scale or bulk production capacity outside the home producer or developers

wherever this is applicable.

Fabric and Accessories Store Department

After receiving purchase order from the buyer merchandiser plans

and issues purchase order for buying raw materials like fabric, buttons,

thread, and for dyeing, printing, embroidery and other accessories. These raw

materials’ are checked for colour, quality and then approved by the

merchandiser.

Spreading, Marker Planning and Cutting Department

Approved sample, pattern and measurement chart must be ready in

the department. The head of the department will be a pattern master. His skill

will be a very big asset to the company by way of saving the fabric and making

new designs for the export trade.

Machinery required: one cutting machine. One table of 18

m/1.5m length and breadth

Spreading

In the cutting department, spreading plays a vital role. In

spreading, the number of plies of fabric, that the production planning process

has dictated to the length of the marker plan, colours required are correctly

aligned as to length and width, and without tension. This saves time, cost of

cutting and cost of materials.

Marker Planning

The amount of fabric consumed per garment and the total profit of

the garment unit is decided by the marker planning and marker making. The

length and width of the marker is very important here. Based on this marker

only the spreading length will be decided. The fabric consumptions and fabric

wastages depends on this marker making. The industry has always paid great

attention to marker planning, because when the cutting room cuts cloth it

spends around half the company’s turnover. Any reduction in the amount of cloth

used per garment leads to increased profit.

Sewing

Power operated machines preferably batch system is used to get

uniform quality andbetter productivity. Production in charge will be

responsible for the sewing operation. He must know quality aspects in every

stage, guide tailors and supervisors to get the work done at satisfactory level

and to meet the targets. Additional to sewing machines, attachments, guides,

folders are required for special operations. Machines like Double needle, Feed

of arm, Button Hole and Buttoning machines are also required.

Washing Department

Either for effects or shrinkage garments are washed. Washes vary

depending upon the type of fabric used and the type of garment. Some of the

common washes are garment wash, stone wash, caustic wash, bleaching acid wash,

sand wash and enzyme wash.

Machinery required : Washing machine, Hydro Extractor, Tumbler

Drier, Store/ Chemicals

Quality Control

Quality is an important concept in all stages of garment

production. To get the quality product, check and controls must be ensured in

each stage of the production. This will also avoid all kinds of mistakes.

Prevention is better than cure and also do the things right at the

first time. These will really bring an awareness in the production line. By any

chance an alteration or a mistake in the garment is difficult to be rectified

properly. For upkeep of quality, good housekeeping and cleanliness should be of

top priority.

Pressing and Folding

Presentation of a packed garment makes all the difference in

sales. The real skill of the industry lies in this point. A well-tailored

garment can be finished badly or a badly stitched garment can be presented

properly. Garments can be folded as follows:

1.

Stand up pack

2.

Plat pack

3.

Deadmen fold

4.

Semi stand pack

Machinery Required

Steam pressing with vacuum table, Dummy blowers, Shift folding tables, Stain removing guns.

Packing and Despatching

In the garment export trade packing is an art and is a very

important stage. If the presentation and packing is good, it will really

attract customers and sales will be faster. Our ultimate aim must be to impress

the buyer with quality product. While packing, ratios, size, colour, tables are

to be observed and followed meticulously. As policy matters decision taking or

making has to be done as early as possible. Delay in minutes/ hours will create

problems and losses. Concentration, involvement and commitment will fetch real

good foreign exchange to the entrepreneur and to the country in the

international market.

Administrative Department

All the departments in a clothing industry require administrative

support for their operations to ensure orderly and systematic functioning. The

procedure covers preparing orders to supplies, checking goods, timing and

methods of stock taking, imports and exports, obtaining credits for returned

goods and materials, issuing credit for customer returns, negotiating and

issuing tenders for major projects and purchase of furniture and equipments.

Related Topics