Chapter: Civil : Prestressed Concrete Structures : Theory and Behaviour

Prestressed Concrete Structures: Losses

Losses

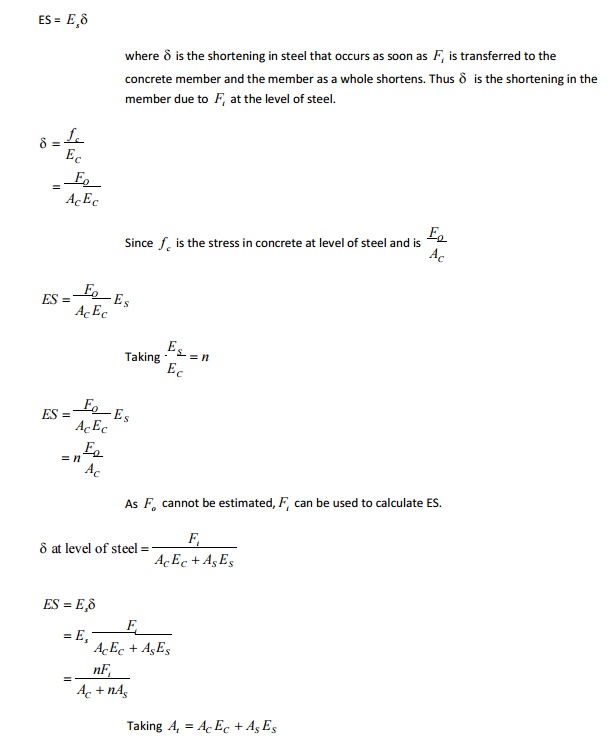

Elastic Shortening (ES) - Cl

18.5.2.4

Shortening

in steel that occurs as soon as Fi is transferred to the concrete member and

the member as a whole shortens.

Fi

= Pre-stress just before transfer

F

= Final stress after losses

Fo

= Immediately after transfer - very difficult to estimate

Note:

The value of Fo may not be known, but it is not necessary, as the losses from

Fi to Fo small percentage of Fi . Total accuracy is relative anyway, as Ec - the

young's modulus of concrete cannot be determined accurately.

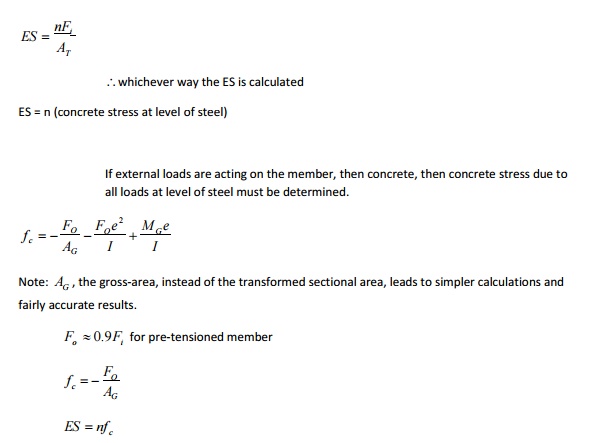

Creep (CR) Cl 18.5.2.1

Among

the many factors affecting creep are volume to surface ratio, age of concrete

at time of pre- stress, relative humidity, type of concrete (lightweight /

normal). Creep is assumed to occur in the member after permanent loads are

imposed after pre-stress. Creep occurs over a long period of time under

sustained load. Part of initial compressive strain induced in concrete

immediately after transfer is reduced by the tensile strain produced by

superimposed permanent loads.

Therefore

for bonded members, loss due to creep

fcds

= stress in concrete at steel level due to superimposed dead loads applied to

the member after transfer of pre-stress

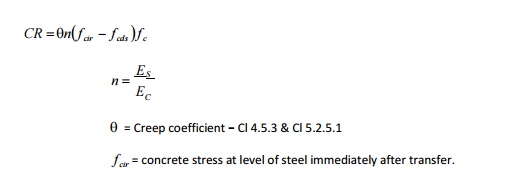

Shrinkage of concrete (SH) Cl

18.5.2.2

Factors

like volume to surface ratio, relative humidity, time from end of moist curing

to application of pre-stress, affect shrinkage in concrete. Shrinkage is

time-dependant and about 80% of the final loss due to shrinkage occurs in the

first year and 100% after several years.

Shrinkage

strain

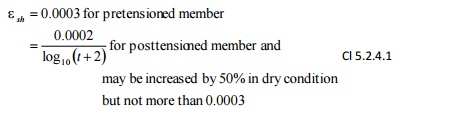

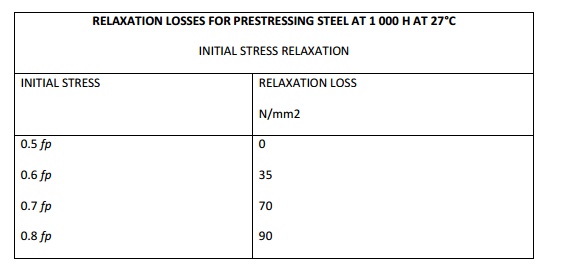

Relaxation of steel (RE) Cl

18.5.2.3

When

elongation is sustained over pre-stressing cable for a long time, the

pre-stress will decrease gradually. The RE - loss due to relaxation depends on

type of steel, time, as well as the ratio of fi/fp i

where fi is the initial pre-stress and fp is the characteristic

strength of steel.

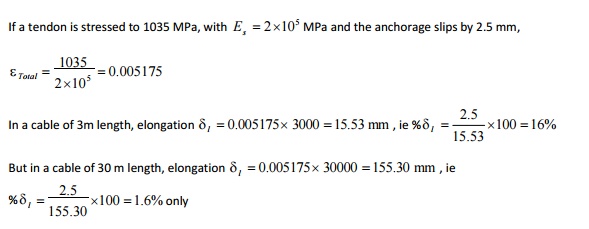

Anchorage slip (ANC) Cl 18.5.2.5

In

post-tensioning, when the jack is released, the full pre-stress is transferred

to the anchorage and they tend to deform, allowing the tendon to slacken.

Friction wedges will slip a little before they grip the wire firmly. So, in

post-tensioning the wedges are positively engaged before the jack is released.

In pre- tensioning also, the anchorage slip is compensated for during stressing

operation.

The

loss is caused by a fixed shortening of the anchorages, so the percentage loss

is higher in shorter wires than in long ones.

Frictional loss Cl 18.5.2.6

Frictional

loss comprise of two parts: (1) The length effect and (2) The curvature effect.

The length effect or the wobble effect of the duct is the friction that will

exist between straight tendon and the surrounding material. This loss is

dependant on the length and stress in the tendon, the coefficient of friction

between the contact materials, the workmanship and the method used in aligning

and obtaining the duct.

The

curvature effect is the loss due to intended curvature of the tendon. This

again depends on the coefficient of friction between the materials and the

pressure exerted by the tendon on the curvature.

For

un-bonded tendon, lubrication, in the form of grease and plastic tube wrapping

can be used to advantage.

For

bonded tendon lubricant in the form of water soluble oils are used during

stressing operation and flushed off with after before grouting.

Jacking

from both ends of the beam will also reduce loss due to friction.

For

straight or moderately curved structures, with curved or straight cables, the

value of pre-stressing force Px at a distance x meters from tensioning end and

acting in the direction of the tangent to the curve of the cable, shall be

calculated as below:

Px

= Poe - ( ?? + kx ).

Where

Po = pre-stressing force in the pre-stressed steel at the tensioning end acting

in the direction of the tangent to the curve of the cable, ? = cumulative angle

in radians through which the tangent to the cable profile has turned between

any two points under consideration, ? = coefficient of friction in curve;

unless otherwise proved by tests, ? may be taken as: 0.55 for steel moving on

smooth concrete, 0.30 for steel moving on steel fixed to duct, and 0.25 for

steel moving on lead, k = coefficient for wobble or wave effect varying from 15

× 10-4 to 50 × 10-4 per meter. The expansion of the equation for Px for small

values of (?? + kx) may be Px = Po (1 - ?? - kx).

Examples

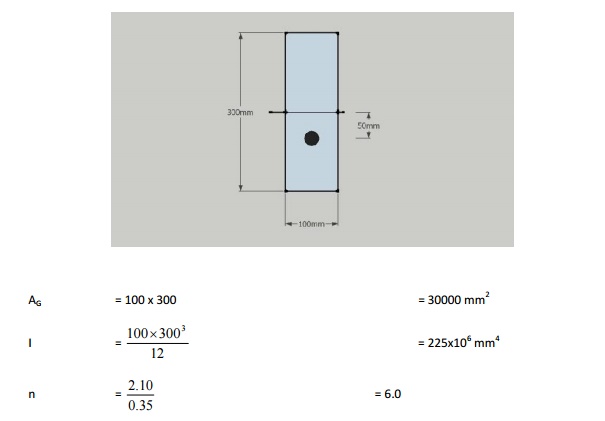

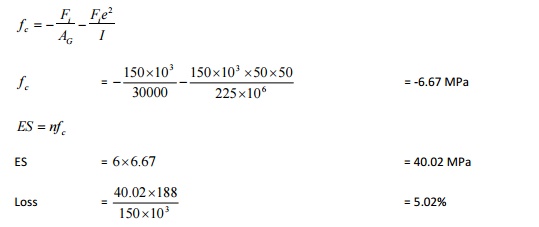

To calculate ES in Pre-tensioned

beam - eccentric tendon

A

pre-tensioned beam of 100 mm x 300 mm is pre-stressed by straight wires with Fi

= 150 kN at an e = 50 mm. ES = 2.1x10 MPa, EC = 0.35x105

MPa and AP = 188 mm Estimate ES

ES in Pre-tensioned beam - concentric

tendon

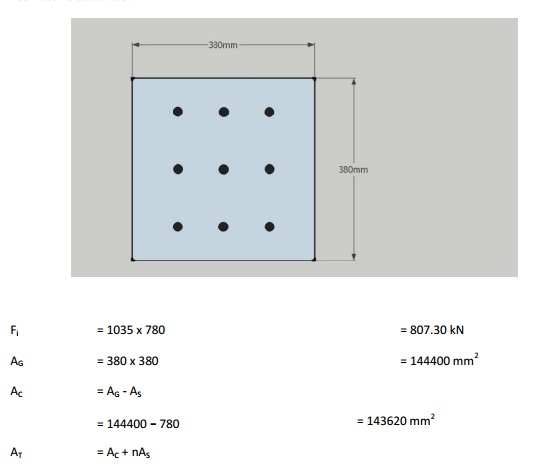

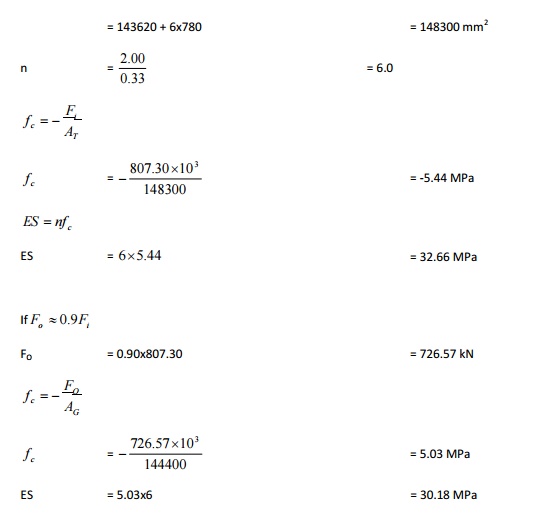

A

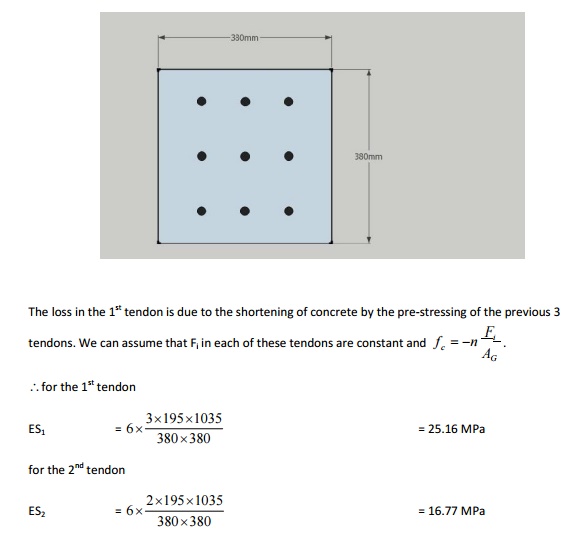

straight pre-tensioned beam 12 m long of 380 mm x 380 mm is concentrically

pre-stressed with 780 mm 2 wires anchored to bulkheads with a fi =

1035 MPa. Es = 2x105 MPa, Ec=0.33x105

Mpa

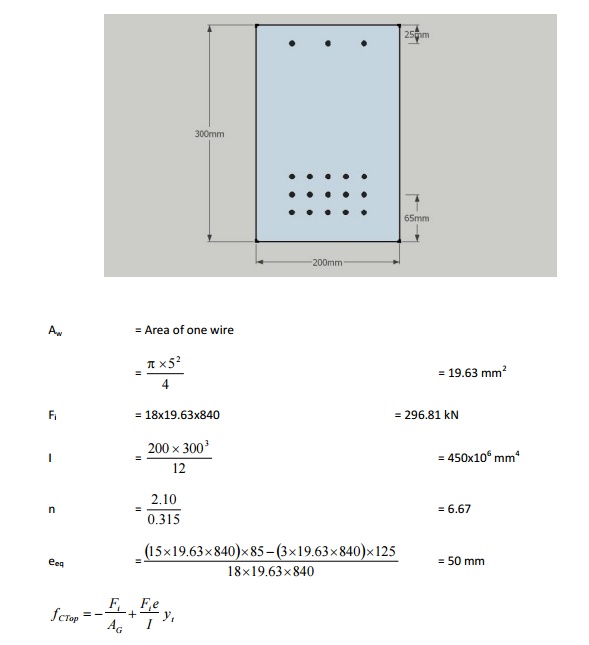

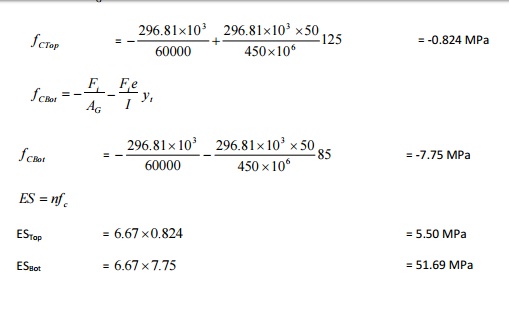

ES in Pre-tensioned beam -

Eccentric tendons at top & bot

A

pre-tensioned beam of 200 mm x 300 mm is pre-stressed with 15#5mm f wires located at 65 mm from the bottom of the beam and 3#5mm ? wires

located at 25mm from the top of the beam. f i =

840MPa.ES =2.x10MPa,EC =0.315x105

MPa Estimate ES. transfer.

To calculate ES in Post-tensioned

beam

A

straight post-tensioned beam 12 m long of 380 mm x 380 mm is concentrically

pre-stressed with 780 mm2 wires made up of 4 tendons with 195 mm2 and the tendons are pre-stressed sequentially

with a f = 1035 MPa. ES = 2x10 MPa, EC = 0.33x105 MPa. Estimate ES

at transfer.

To calculate CR, SH and RE in

post-tensioned beam

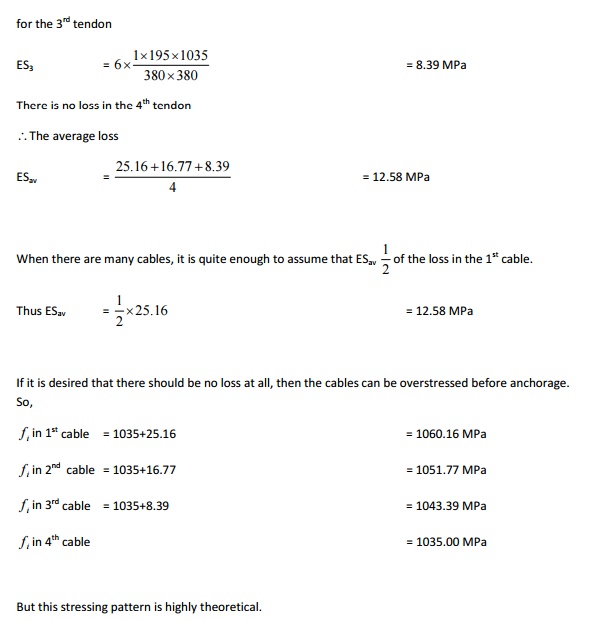

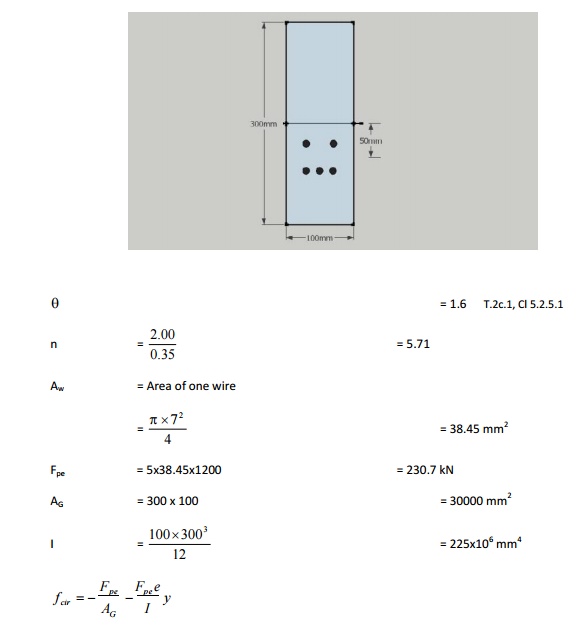

A

straight post-tensioned beam of size 100 mm x 300 mm is pre-stressed with 5

wires of 7 mm f.

The 5 average pre-stress after short-term losses is f pe= 1200 MPa.

The gae at loading is 28 days. ES = 2x105 MPa, EC = 0.35x105 MPa. Estimate

CR, SH and RE assuming fp = 1715 MPa.

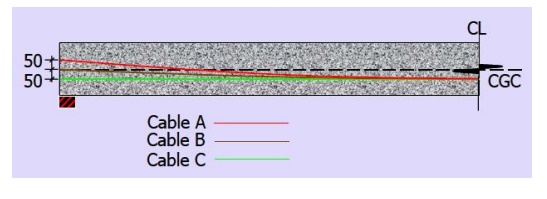

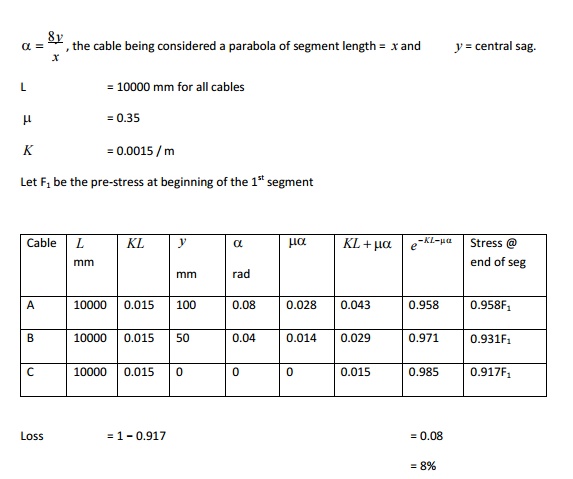

To calculate frictional losses -

tensioned from one end

A

post-tensioned beam 100 mm × 300 mm of le = 10 m is stressed by successive

tensioning and anchoring of 3 cables A, B, and C respectively as shown in

figure. Each cable has cross section area of 200 mm2 and has initial

stress of 1200 MPa. If the cables are tensioned from one end, estimate the

percentage loss in each cable due to friction at the anchored end. Assume ? =

0.35, K = 0.0015 / m.

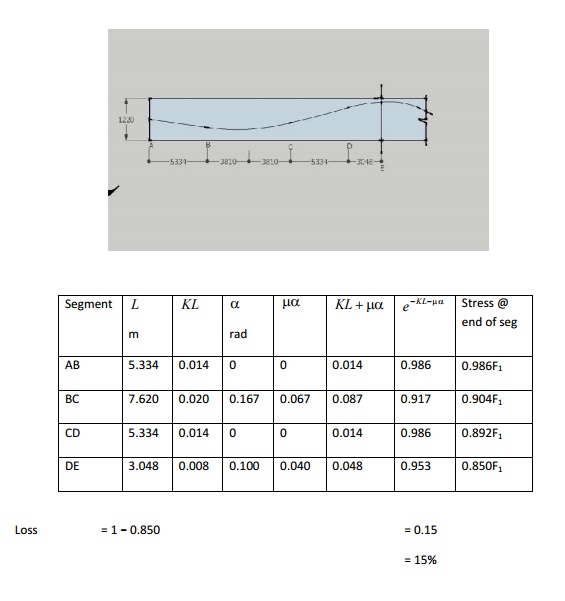

To calculate frictional losses -

tensioned from both ends

A

pre-stressed concrete beam is continuous over two spans and its curved tendon

is to be tensioned from both ends. Compute the percentage of loss of pre-stress

due to friction from one end to the center of the beam (A-E). The coefficient

of friction between the cable and the duct is 0.40 and the average wobble or

length effect is represented by k = 0.0026/m. The cable is straight between A-B

and C-D. The change in angle between BC is 0.167 radians and that between DE is

0.100 radians.

Related Topics