Chapter: Civil : Construction Materials: Timber And Other Materials

Preparation Of Paint

Characteristics Of An Ideal Paint

The requirements are uniform

spread as a thin film, high coverage, good workability and durability,

sufficient elasticity to remain unaffected by expansion or contraction of the

surface to be painted or by weathering action of atmosphere. The paints should

also be: impervious to air and water, cheap and economical to form a hard

surface.

Preparation Of Paint

The base is ground in a vehicle

to the consistency of paste in a stone pestle known as muller. Linseed oil, is

intermittently added to the paste in small quantities and the mixture is

stirred with a wooden puddle. In case of coloured paints, the pigment is mixed

with linseed oil separately and the paste is formed as explained above. Driers

are also ground separately in linseed oil. The three pastes so prepared are

mixed and a little linseed oil is added further to soften the paste. The

mixture is continuously stirred till a consistency of cream is obtained. The

mixture is thereafter strained through fine canvas or a sieve. The paint is now

ready for use. The paint so prepared can be used by adding oil or a thinner to

make it of workable consistency before application.

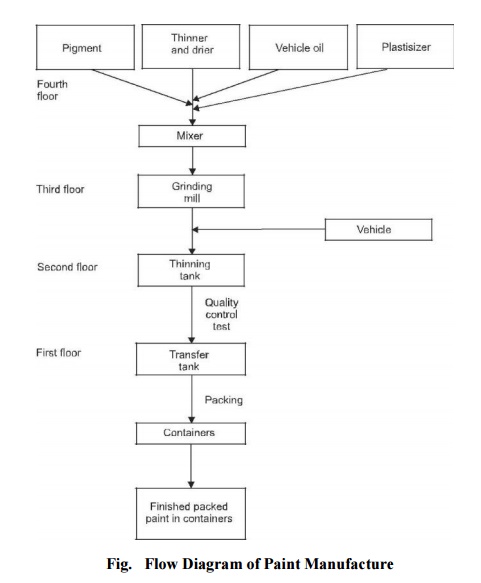

For commercial manufacturing of

paints a four-storey building is used to have gravitational flow of materials.

Pigments, oil, thinner, plasticizer, drier, etc. are stored on the fourth floor

and are fed by means of chutes in proper proportions, to the grinding mill

placed on the third floor and are ground. The thoroughly ground materials are

then sent to storage tanks on the second floor. The charge in the tanks is kept

in motion by agitation mechanism so that settling of materials does not take

place. An additional quantity of vehicle is added here to get the desired

composition. The batch is then tested for quality control. The paint material

is then strained and sent to first floor, where it is packed in containers.

Finally the packed material in containers is sent to the ground floor. A flow diagram

of paint manufacture is shown in Fig.

The

factors affecting the quality of paint so prepared are quality of ingredients,

grinding, intimate mixing and proportioning, straining, packing, etc. Ready

mixed paints are also available in the market with different trade names, e.g.,

Asian, Ducco, Shalimar, Berger Nerolac, etc.

Related Topics