Chapter: Power Quality : Power Quality Monitoring

Power Quality Measurement Equipment

POWER QUALITY MEASUREMENT

EQUIPMENT

They

include everything from very fast transient over voltages (microsecond time

frame) to long-duration outages (hours or days time frame). Power quality

problems also include steady-state phenomena, such as harmonic distortion, and

intermittent phenomena, such as voltage flicker.

1. Types of instruments

Although

instruments have been developed that measure a wide variety of disturbances, a

number of different instruments may be used, depending on the phenomena being

investigated. Basic categories of instruments that may be applicable include

■ Wiring

and grounding test devices

■ Multimeters

■ Oscilloscopes

■ Disturbance

analyzers

■ Harmonic

analyzers and spectrum analyzers

■ Combination

disturbance and harmonic analyzers

■ Flicker

meters

■ Energy

monitors

Besides

these instruments, which measure steady-state signals or disturbances on the

power system directly, there are other instruments that can be used to help

solve power quality problems by measuring ambient conditions:

1.

Infrared meters can be very valuable in detecting

loose connection sand overheating conductors. An annual procedure of checking

the system in this manner can help prevent power quality problems due to

arcing, bad connections, and overloaded conductors.

2. Noise

problems related to electromagnetic radiation may require measurement of field

strengths in the vicinity of affected equipment. Magnetic gauss meters are used

to measure magnetic field strengths for inductive coupling concerns. Electric

field meters can measuret he strength of electric fields for electrostatic

coupling concerns.

3. Static

electricity meters are special-purpose devices used to measure static

electricity in the vicinity of sensitive equipment. Electrostatic discharge

(ESD) can be an important cause of power quality problems in some types of

electronic equipment.

Regardless

of the type of instrumentation needed for a particular test, there are a number

of important factors that should be considered when selecting the instrument.

Some of the more important factors include

Ø Number of

channels (voltage and/or current)

Ø Temperature

specifications of the instrument

Ø Ruggedness

of the instrument

Ø Input

voltage range (e.g., 0 to 600 V)

Ø Power

requirements

Ø Ability

to measure three-phase voltages

Ø Input

isolation (isolation between input channels and from each input to ground)

Ø Ability

to measure currents

Ø Housing

of the instrument (portable, rack-mount, etc.)

Ø Ease of

use (user interface, graphics capability, etc.)

Ø Documentation

Ø Communication

capability (modem, network interface)

Ø Analysis

software

The

flexibility (comprehensiveness) of the instrument is also important. The more

functions that can be performed with a single instrument, the fewer the number

of instruments required

Wiring and grounding testers:

Many

power quality problems reported by end users are caused by problems with wiring

and/or grounding within the facility. These problems can be identified by

visual inspection of wiring, connections, and panel boxes and also with special

test devices for detecting wiring and grounding problems.

Important

capabilities for a wiring and grounding test device include

Ø Detection

of isolated ground shorts and neutral-ground bonds

Ø Ground

impedance and neutral impedance measurement or indication

Ø Detection

of open grounds, open neutrals, or open hot wires

Ø Detection

of hot/neutral reversals or neutral/ground reversals

Three-phase

wiring testers should also test for phase rotation and phase-to-phase voltages.

These test devices can be quite simple and provide an excellent initial test

for circuit integrity. Many problems canbe detected without the requirement for

detailed monitoring using expensive instrumentation.

Multimeters:

After

initial tests of wiring integrity, it may also be necessary to make quick

checks of the voltage and/or current levels within a facility. Overloading of

circuits, under voltage and overvoltage problems, and unbalances between

circuits can be detected in this manner. These measurements just require a

simple multi meter. Signals used to check for these include

Ø Phase-to-ground

voltages

Ø Phase-to-neutral

voltages

Ø Neutral-to-ground

voltages

Ø Phase-to-phase

voltages (three-phase system)

Ø Phase

currents

Ø Neutral

currents

The most

important factor to consider when selecting and using a multimeter is the

method of calculation used in the meter. All the commonly used meters are

calibrated to give an rms indication for the measured signal. However, a number

of different methods are used to

calculate

the rms value. The three most common methods are

1. Peak method. Assuming the signal to be a

sinusoid, the meter reads the peak of the signal and divides the result by 1.414 (square root of 2) to obtain the rms.

2. Averaging method. The meter determines the average value of a

rectified signal. For a clean sinusoidal

signal (signal containing only one frequency), this average value is related to

the rms value by a constant.

3. True rms. The rms value of a signal is a

measure of the heating that will result if the voltage is impressed across a resistive load. One method of detecting the

true rms value is to actually use a thermal detector to measure a heating

value. More modern digital meters use a digital calculation of the rms value by

squaring the signal on a sample by-sample basis, averaging over the period, and

then taking the square root of the result. These different methods all give the

same result for a clean, sinusoidal signal but can give significantly different

answers for distorted signals. This is very important because significant

distortion levels are

2. Disturbance analyzers

Disturbance

analyzers and disturbance monitors form a category of instruments that have

been developed specifically for power quality measurements. They typically can

measure a wide variety of system disturbances from very short duration

transient voltages to long-duration outages or under voltages. Thresholds can

be set and the instruments left unattended to record disturbances over a period

of time. The information is most commonly recorded on a paper tape, but many

devices have attachments so that it can be recorded on disk as well.

There are

basically two categories of these devices:

1. Conventional analyzers that summarize events

with specific information such as overvoltage and undervoltage magnitudes, sags

and surge magnitude and duration, transient magnitude and duration, etc.

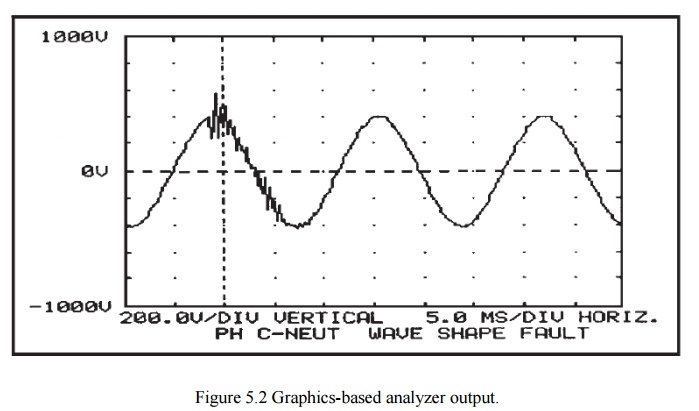

2. Graphics-based analyzers that save and print the

actual waveform along with the descriptive information which would be generated

by one of the conventional analyzers

It is

often difficult to determine the characteristics of a disturbance or a

transient from the summary information available from conventional disturbance

analyzers. For instance, an oscillatory transient cannot be effectively

described by a peak and a duration. Therefore, it is almost imperative to have

the waveform capture capability of a graphics-based disturbance analyzer for

detailed analysis of a power quality problem (Fig. 5.2). However, a simple conventional

disturbance monitor can be valuable for initial checks at a problem location.

3. Spectrum analyzers and

harmonic analyzers

Harmonic

analyzers have several capabilities. They capture harmonic waveforms and

display them on a screen. They calculate the K factor to de rate transformers

and the total harmonic distortion (THD) in percent of the fundamental. They

also measure the corresponding frequency

spectrum, i.e., the harmonic frequency associated with the current and voltage

up to the fiftieth harmonic.

They

display the harmonic frequency on a bar graph or as the signal’s numerical

values.

Some

measure single-phase current and voltage while others measure three-phase

current and voltage. All of them measure the power factor (PF). The power

factor provides a measurement of how much of the power is being used

efficiently for useful work. Some can store data for a week or more for later

transfer to a PC for analysis.

This

makes them powerful tools in the analysis of harmonic power quality problems.

Some of the more powerful analyzers have add-on modules that can be used for

computing fast Fourier transform (FFT) calculations to determine the

lower-order harmonics. However, any significant harmonic measurement

requirements will demand an instrument that is designed for spectral analysis

or harmonic analysis. Important capabilities for useful harmonic measurements

include Capability to measure both voltage and current simultaneously so that

harmonic power flow information can be obtained.

■

Capability to measure both magnitude and phase angle of individual harmonic

components (also needed for power flow calculations).

■ Synchronization and a sampling rate fast enough

to obtain accurate measurement of harmonic components up to at least the 37th

harmonic (this requirement is a combination of a high sampling rate and a

sampling interval based on the 60-Hz fundamental).

■ Capability to characterize the statistical nature

of harmonic distortion levels (harmonics levels change with changing load

conditions and changing system conditions).

There are basically three categories of instruments

to consider for harmonic analysis:

1. Simple meters. It may sometimes be necessary

to make a quick check of harmonic levels

at a problem location. A simple, portable meter for this purpose is ideal.

There are now several hand-held instruments of this type on the market. Each

instrument has advantages and disadvantages in its operation and design. These

devices generally use microprocessor-based circuitry to perform the necessary

calculations to determine individual harmonics up to the 50th harmonic, as well

as the rms, the THD, and the telephone influence factor (TIF). Some of these

devices can calculate harmonic powers (magnitudes and angles) and can upload

stored waveforms and calculated data to a personal computer.

2. General-purpose spectrum analyzers.

Instruments in this category are designed to perform spectrum analysis on waveforms for a wide variety of

applications. They are general signal analysis instruments. The advantage of

these instruments is that they have very powerful capabilities for a reasonable

price since they are designed for a broader market than just power system

applications. The disadvantage is that they are not designed specifically for

sampling power frequency waveforms and, therefore, must be used carefully to

assure accurate harmonic analysis. There are a wide variety of instruments in

this category.

3. Special-purpose power system harmonic analyzers. Besides

the general-purpose spectrum

analyzers just described, there are also a number of instruments and devices

that have been designed specifically for power system harmonic analysis. These

are based on the FFT with sampling rates specifically designed for determining

harmonic components in power signals. They can generally be left in the field

and include communications capability for remote monitoring.

4. Flicker meters

Over the

years, many different methods for measuring flicker have been developed. These

methods range from using very simple rms meters with flicker curves to

elaborate flicker meters that use exactly tuned filters and statistical

analysis to evaluate the level of voltage flicker. This section discusses

various methods available for measuring flicker.

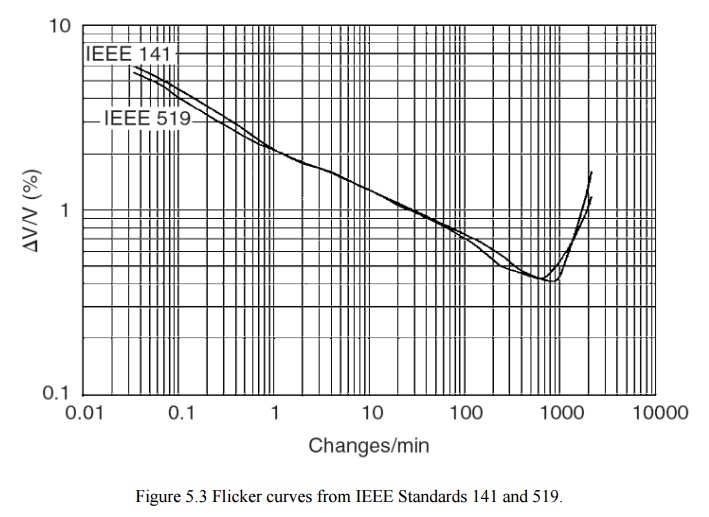

Flicker standards. Although

the United States does not currently have a standard for flicker measurement, there are IEEE standards

that address flicker. IEEE Standards 141-19936 and 519-19927 both contain

flicker curves that have been used as guides for utilities to evaluate the

severity of flicker within their system. Both flicker curves, from Standards

141 and 519, are shown in Fig. 5.3. In other countries, a standard methodology

for measuring flicker has been established. The IEC flicker meter is the

standard for measuring flicker in Europe and other countries currently adopting

IEC standards. The IEC method for flicker measurement, defined in IEC Standard

61000-4-158 (formerly IEC 868), is a very comprehensive approach to flicker

measurement and is further described in “Flicker Measurement Techniques” below.

More recently, the IEEE has been working toward adoption of the IEC flicker

monitoring standards with an additional curve to account for the differences

between 230-V and 120-V systems.

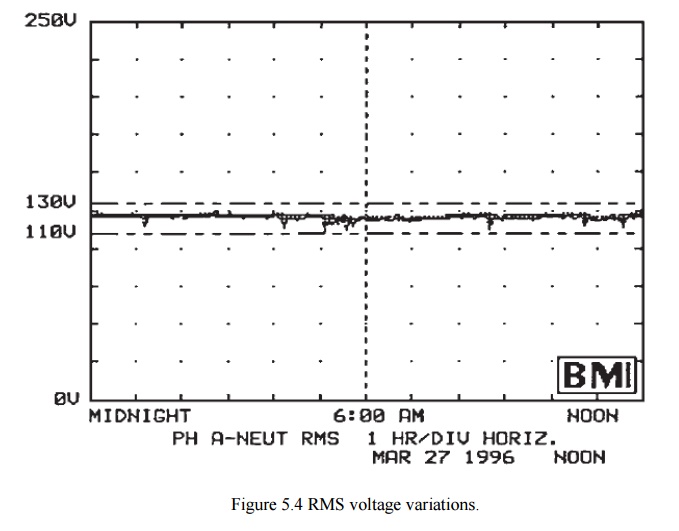

Flicker measurement techniques

RMS strip charts. Historically,

flicker has been measured using rms meters, load duty cycle, and a flicker curve. If sudden rms

voltage deviations occurred with specified frequencies exceeding values found

in flicker curves, such as one shown in Fig. 5.3, the system was said to have

experienced flicker. A sample graph of rms voltage variations is shown in Fig.

5.4 where large voltage deviations up to 9.0 V rms (_V/V _ ± 8.0 percent on a

120-V base) are found. Upon comparing this to the flicker curve in Fig. 5.3,

the feeder would be experiencing flicker, regardless of the duty cycle of the

load producing the flicker, because any sudden total change in voltage greater

than 7.0 V rms results in objectionable flicker, regardless of the frequency.

The advantage to such a method is that it is quite simple in nature and the rms

data required are rather easy to acquire. The apparent disadvantage to such a

method would be the lack of accuracy and inability to obtain the exact

frequency content of the flicker.

Fast Fourier transforms. Another

method that has been used to measure flicker is to take raw samples of the actual voltage waveforms and implement a fast

Fourier transform on the demodulated signal (flicker signal only) to extract

the various frequencies and magnitudes found in the data. These data would then

be compared to a flicker curve. Although similar to using the rms strip charts,

this method more accurately quantifies the data measured due to the magnitude

and frequency of the flicker being known. The downside to implementing this

method is associated with quantifying flicker levels when the flicker-producing

load contains multiple flicker signals. Some instruments compensate for this by

reporting only the dominant frequency and discarding the rest.

Flicker meters. Because of the complexity of

quantifying flicker levels that are based upon human perception, the most comprehensive approach to measuring

flicker is to use flicker meters. A flicker meter is essentially a device that

demodulates the flicker signal, weights it according to established “flicker

curves,” and performs statistical analysis on the processed data.

Generally,

these meters can be divided up into three sections. In the first section the

input waveform is demodulated, thus removing the carrier signal. As a result of

the demodulator, a dc offset and higher-frequency terms (sidebands) are

produced. The second section removes these unwanted terms using filters, thus

leaving only the modulating (flicker) signal remaining. The second section also

consists of filters that weight the modulating signal according to the

particular meter specifications. The last section usually consists of a

statistical analysis of the measured flicker.

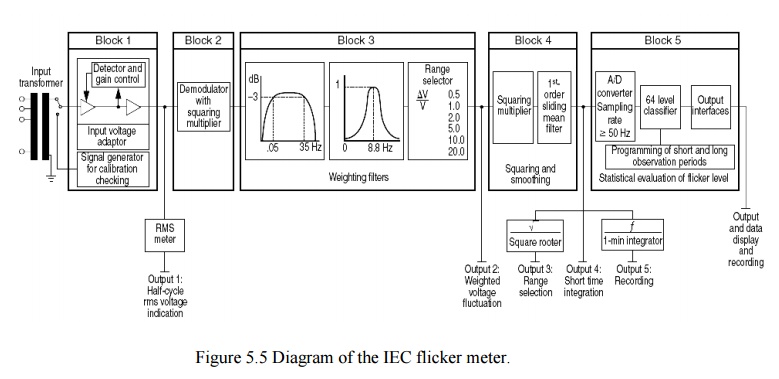

The most

established method for doing this is described in IEC Standard 61000-4-15.8 The

IEC flicker meter consists of five blocks, which are shown in Fig. 5.5.

Block 1

is an input voltage adapter that scales the input half-cycle rms value to an

internal reference level. This allows flicker measurements to be made based

upon a percent ratio rather than be dependent upon the input carrier voltage

level.

Block 2

is simply a squaring demodulator that squares the input to separate the voltage

fluctuation (modulating signal) from the main voltage signal (carrier signal),

thus simulating the behavior of the incandescent lamp.

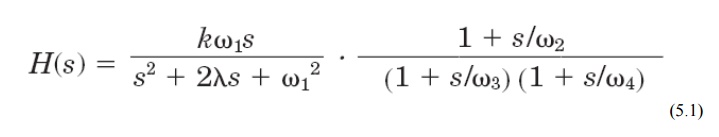

Block 3

consists of multiple filters that serve to filter out unwanted frequencies

produced from the demodulator and also to weight the input signal according to

the incandescent lamp eye-brain response. The basic transfer function for the

weighting filter is

Block 4

consists of a squaring multiplier and sliding mean filter. The voltage signal

is squared to simulate the nonlinear eye-brain response, while the sliding mean

filter averages the signal to simulate the short-term storage effect of the

brain. The output of this block is considered to be the instantaneous flicker

level. A level of 1 on the output of this block corresponds to perceptible

flicker.

Block 5

consists of a statistical analysis of the instantaneous flicker level. The

output of block 4 is divided into suitable classes, thus creating a histogram.

A probability density function is created based upon each class, and from this

a cumulative distribution function can be formed.

Flicker

level evaluation can be divided into two categories, short term and long-term.

Short-term evaluation of flicker severity PST is based upon an observation

period of 10 min. This period is based upon assessing disturbances with a short

duty cycle or those that produce continuous fluctuations. PST can be found

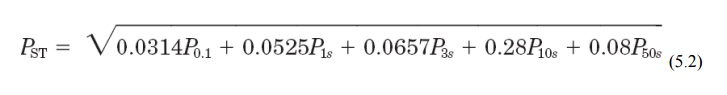

using the equation

where the

percentages P0.1, P1s, P3s, P10s, and P50s are the flicker levels that are

exceeded 0.1, 1.0, 3.0, 10.0, and 50.0 percent of the time, respectively. These

values are taken from the cumulative distribution curve discussed previously. A

PST of 1.0 on the output of block 5 represents the objectionable (or irritable)

limit of flicker.

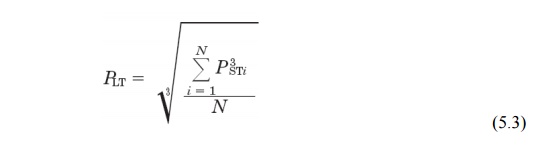

For cases

where the duty cycle is long or variable, such as in arc furnaces, or

disturbances on the system that are caused by multiple loads operating

simultaneously, the need for the long-term assessment of flicker severity

arises. Therefore, the long-term flicker severity PLT is derived from PST using

the equation

where N

is the number of PST readings and is determined by the duty cycle of the

flicker-producing load. The purpose is to capture one duty cycle of the

fluctuating load. If the duty cycle is unknown, the recommended number of PST

readings is 12 (2-h measurement window). The advantage of using a single

quantity, like Pst, to characterize flicker is that it provides a basis for

implementing contracts and describing flicker levels in a much simpler manner.

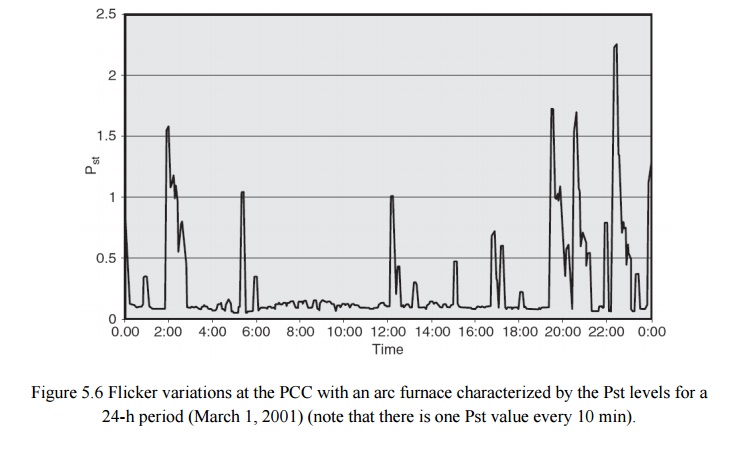

Figure 11.19 illustrates the Pst levels measured at the PCC with an arc furnace

over a 24-h period. The melt cycles when the furnace was operating can be

clearly identified by the high Pst levels. Note that Pst levels greater than

1.0 are usually considered to be levels that might result in customers being

aware of lights flickering.

Related Topics