Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track Maintenance

Organization Structure for Railway Track Maintenance

Organization Structure for Track

Maintenance

Track maintenance on Indian Railways is a well-organized

affair as described below.

1 Organization at the Headquarters

The primary duty of maintaining

the track lies with the civil engineering branch headed by the principal chief

engineer stationed at the head quarters of each zonal railway. He is assisted

by a number of functional chief engineers such as the chief track engineer

(CTE), the chief bridge engineer (CBE), the chief engineer planning and design

(CPDE), and the chief engineer general (CGE). Normally, one functional chief

engineer is in charge of one division or more and supervises the work of that

division in all civil engineering matters. Each chief engineer is assisted by

deputy chief engineers, executive engineers, etc., who are responsible for

planning, designing, and providing the necessary materials along with providing

any other assistance that may be required by the field engineers.

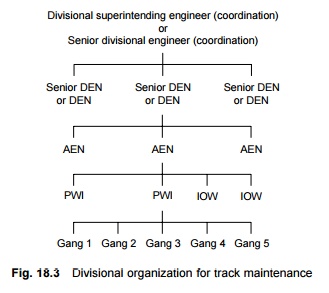

2 Organization at the Divisions

The

direct responsibility of the maintenance of civil engineering assets, including

the track, lies with the division. In each division, there are one or more

divisional superintending engineers (DSE) or senior divisional engineers (sr

DEN) who work under the administrative control of the divisional railway

manager and the technical control of the chief engineer. Figure 18.3 gives the

details of the divisional organization for track maintenance.

Each divisional superintending

engineer (DSE) or senior divisional engineer has complete charge of a division.

He or she is assisted by two to three divisional engineers (DENs), each with

about 1000 integrated track kilometres under his or her charge. Every DEN is

assisted by two to three assistant engineers (AENs), each in charge of about

400 kilometres of track. An AEN in turn is aided by two to three permanent way

inspectors, who are directly responsible for the safety and maintenance of the

track. Each AEN is also assisted by one or more inspector of works (IOW) who

look after all the work. The track maintenance work is done by various gangs,

each of which is headed by a mate who has about 10 to 20 gangmen working under

him or her. Each gang has a keyman, who inspects the track daily to ensure its

safety. The duties of AENs, PWIs, and other permanent way officials are

explained briefly in the subsequent sections.

3 Duties of Permanent Way Officials

The permanent way officials in

charge of maintaining the track have to ensure that the finest standards of

track maintenance are followed as per the prescribed procedures at the minimum

cost. The duties of all PW officials have, therefore, been specified so that

they can work systematically to achieve the desired objectives. This chapter

only outlines the essential duties of PW officials. In actual practice,

however, they have to carry out many more miscellaneous functions as per the

traditions and practices of Indian Railways.

4 Duties of Assistant Engineer

The

assistant engineer is generally responsible for the maintenance and safety of

all way and works under his or her charge, for the accuracy, quality, and

progress of any new work that may be undertaken and for controlling all

expenditure with respect to the budget allotment.

The

essential duties of an AEN are as follows.

(a) Inspection

and maintenance of track and all track structures to ensure satisfactory and

safe performance

(b) Preparation

of plans and estimates; execution and assessment of work

(c) Verification

of stores held by stockholders

(d) Submission

of proposals for inclusion in the track renewal programme,

estimates

of revenue budget, and work programme

An AEN is

also required to carry out the following inspections.

Trolley inspection The

entire subdivision should be inspected once a month by assistant

engineer, as far as possible with the help of a push trolley. This inspection

should be intensive and should include the checking of gang attendance, the

work done by the gang, the equipment used, and an examination of gang

charts/diaries with reference to the prescribed track maintenance schedule.

During the inspection, the assistant engineer should check the work done by one

or two gangs under each PWI and record his or her observations.

Fast train inspection Either

the foot plate of the engine or the last vehicle of a fast train should

traverse the entire length of the subdivision once a month.

Inspection of level crossings The

assistant engineer should inspect all manned level crossings once every

six months. He or she should examine the gatemen's knowledge of the rules and

check the equipment, track, road approaches, and all other safety aspects of

each crossing.

Checking of curves The AEN

should verify the versine and superelevation of at least one curve under

the jurisdiction of every PWI every quarter.

Checking of points and crossings Once a

year the AEN should inspect all the points and crossings on passenger

lines and 10% of the points and crossings on other lines.

Monsoon patrolling During

monsoon patrolling, the assistant engineer should use either a train,

push trolley, or motor trolley once every month to check the patrolman's work.

Scrutinizing of registers during

inspection The AEN should scrutinize the various

registers maintained by the PWI such as the creep register, curve register, and

the points and crossings register.

Inspection of bridges The AEN

should inspect all the bridges of his or her subdivision once every year

after the monsoon is over and record the inspection details in the bridge

register. Tracks on girder bridges should also be inspected as part of the

annual bridge inspection.

Inspection of office and stores The AEN

should inspect each office and store of all the PWIs and IOWs under his

or her charge at least once a year. When checking stores, he or she should pay

particular attention to the allocation of the imprest engineering indicators,

protection equipments, and other important items in the stores.

An AEN

also has the following additional duties.

(a) To ensure

that all work is done as per the standard plans and specifications.

(b) To

witness the payments made under one inspector once every month.

(c) To record

the measurements of the ballast or to carry out a thorough check of its quality

and quantity if the same has already been recorded by an inspector. Also, to

test check the measurements of other works.

(d) To reach

an accident site as early as possible and to take the necessary measures to

restore traffic on the affected track.

(e) To

accompany any track recording or oscillograph car runs in his or her section.

(f) To

exercise control on expenditure so as to contain it within the alloted budget.

(g) To train

probationers in their work.

(h) To

inspect water purification systems once every three months.

(i) To

inspect all steel structures once every six months.

(j) To look

after the welfare of the staff and to inculcate discipline in them.

(k) To

accompany the GM or other senior railway officials during inspection.

(l) To

coordinate with officials of other departments.

5 Duties of a PWI in Overall Charge

The PWI is generally responsible for the following.

(a) Maintenance

and inspection of the track to ensure satisfactory and safe performance.

(b) Efficient

execution of all works incidental to track maintenance, including track

relaying work.

(c) Accounts

and periodical verification of the stores and tools in his or her charge.

(d) Maintenance

of land boundaries between stations and at important stations

as may be

specified by the administration.

The PWI

also carries out inspections of the following facets of a track.

Testing the track He or she

should run a test check on the foot plate of the engine of fast trains

at least twice a month and in a rear brake van of a fast vehicle once a month,

and make a note of sections where the quality of running is defective and get

them rectified.

Inspection of track and gangs The PWI should

inspect the entire section with the help of a push trolley at least once

a week or more often if necessary.

Level crossing inspection

(a) He or she

should check the equipment assigned to the gateman once a month.

(b) He or she

should periodically examine knowledge of safety rules.

(c) He or she

should ensure that all level crossings are safe.

Points and crossings inspection The PWI

should inspect the points and crossings on passenger lines once in three

months and those on other lines once in six months.

Curve

inspection The PWI should check the versines and

superelevation of each curve once in six months. Based on his or her

observations, the PWI should take the appropriate action to correct the curve,

if necessary.

Inspection diagram The PWI

should maintain an inspection diagram of all inspections carried out

during the month as per the schedule laid down in the pro forma and submit the

same every month to the divisional engineer via the AEN, bringing out the

reasons for failure in adhering to the schedules of inspections, if any.

Safety of track The PWI

is directly responsible for the safety of the track. He or she should be

vigilant so as to promptly locate faults in the permanent way and get them

repaired without delay.

In

addition to the inspections, a PWI also carries out the following duties.

(a) To

accompany high officials during their inspections along with the relevant

records. The PWI should carry all the important measuring equipment such as the

gauge-cum-level, flange gauges, fishing chord, tape, and inspection hammer on

these inspections.

(b) To

accompany any track recording and oscillograph car that runs in his or her

section.

(c) To check

the proximity of trees that are likely to damage the track and get them

removed.

(d) To check

night patrolling at least once a month by train as well as by trolley.

(e) To take

the necessary safety measures while executing maintenance work that affects the

safety of the track.

(f) To rush

to the site of an accident and take the necessary measures to safeguard the

line and restore traffic.

(g) To

periodically inspect and supervise LWR tracks to ensure their safety.

(h) To ensure

the cleanliness of station yards.

(i) To keep

proper records of the training out of ballast.

(j) To

witness the payments made out to the staff every month.

(k) To look

after all establishment work, including the welfare of the staff working under

his charge, and to maintain their service records.

(l) To ensure

the safety of the track during the execution of work that affects

the

track.

Based on the system of

maintenance, the permanent way inspector in charge of the section should

prepare detailed short-term plans covering a month's work (split into weekly

programs) at least a month in advance of the commencement of actual work. The

PWI should ensure that adequate arrangements have been made for the requisite

tools, materials, and manpower for the allotted task and that work is executed

within the specified time. The following procedure of track maintenance is

followed on Indian Railways.

Each mate should be supplied with a gang chart and a gang

register. The gang chart should have a record of the day-to-day track

maintenance work to be done over the gang length, maintained by the permanent

way inspector (PWI) according to specified instructions. The gang registers

contain a record of the weekly programme of the work to be carried out, also

maintained entered by the PWI in charge of the section. At the end of the week,

the PWI should qualitatively and quantitatively assess the completed work and

record his/her observations in the gang register after a detailed inspection of

the work done during the previous week.

(b) Gang

charts or gang registers should be checked by the assistant engineer and

divisional engineer during their inspections. After inspecting the section by

trolley, they should record their observations in the gang register.

(c) On

withdrawal of old gang charts or gang registers and supply of fresh ones, the

PWI should carefully analyse the work done and make a note of those stretches

of the track that frequently gave trouble during the year, with a view to

formulate such special measures as may be necessary.

6 Duties of Mates

Every mate should make sure that

the length of line under his charge is kept safe for the passage of trains.

Sections needing urgent attention should be taken care of without waiting for

orders from PWIs.

Working of permanent way gangs

The track on Indian Railways is

mostly maintained by permanent way gangs. Each permanent way gang has a

strength of about 10-20 people and a beat of about 6- 10 km. The gangs normally

follow the annual programme set for regular track maintenance and complete at

least one round of through packing in a year, depending on various

circumstances. A gang works under the control of a mate who assigns track

maintenance works to the permanent way gangmen.

Tools used by a PW gang Each gang

should have the following maintenance tools and equipment. Worn out

tools and equipment should be replaced every month.

(a) Gauge-cum-level

(b) One set

of red hand-signal flags, two hand-signal lamps for the nights, and 12

detonators

(c) 30-cm-long

steel scale, 1-m-long straight edge, square, hemp, cord, and marking chalk

(d) Wooden

mallet or canne-a-boule, fish bolt spanner, keying and spiking hammer, and

measured shovel packing (MSP) equipment if MSP is required

(e) A

sufficient number of shovels, phowrahs, beaters, crowbars, ballast forks or

rakes, and mortar pans or baskets

Knowledge of safety measures The

permanent way mistry (PWM) mate and all other gang men should have

complete knowledge of the following safety measures.

(a) Method of

protecting the line in an emergency or during maintenance work that affects the

running of trains, including methods of fixing detonators, banner flags, etc.

(b) Displaying

the obligatory signals with or without a hand-signal flag during the day and

with a hand-signal lamp during the night.

(c) Action to

be taken when a train is noticed to have parted.

(d) Patrolling

of lines on LWR tracks during heavy rains, storms, sandstorms, and during hot

weather.

(e) Awareness

of 'safety first' rules.

Gang strength for track maintenance

A track is maintained manually by

gangmen. Each gang has about 10 to 20 persons and a jurisdiction of about 4 to

6 km. In order to ensure uniformity of practice, Indian Railways has prescribed

a standard formula known as the special committee formula for

calculating the number of men to be included in each gang.

N = MKE =

MKLU(1 + A + B + C)

where N is the number of

men per km, M is the manpower factor, K is the correction factor

due to modernization of track, standard of maintenance, etc., E is the

number of equated track kilometres (ETKM) and is equal to L × U(1

+ A + B + C), A, B, and C are

variable factors, L is the length of a single track, and U is the

traffic density that varies from 0.4 to 1.4 depending upon whether the section

is a siding or a busy section with heavy gradients.

The manpower factor M is

the weightage for the actual man-days required to carry out normal permanent

way maintenance work in a year vis-à-vis the actual number of man-days

available. The correction factor K is required as a result of the

modernization of the track. It has been felt that the effort required to

maintain short welded rails and long welded rails is much less as compared to a

fish-plated track.

The variable factors, A, B,

and C denote the following. A is the formation factor, which

varies from 0 to 0.20 depending upon the type of soil, B is the

alignment factor and is equal to 0 where the track is straight and 0.25 when

the entire track is on a curve, and C is the rainfall factor and varies

from 0.10 to 0.20 depending upon whether there is little or heavy rainfall.

7 Duties of Keymen

Once a day, the keyman should

inspect both the track and the bridges on his/her beat. He should go along one

rail on his outward journey and return along the opposite rail on his return

journey.

8 Knowledge of Rules and Signals

Every mate, keyman, and gangman

should have the correct knowledge of handling detonating signals and should be

conversant with the following measures of track maintenance.

(a) Protecting

the line in an emergency and during the execution of maintenance work

(b) Action to

be taken when a train is noticed to have parted

(c) Knowledge

of 'safety first' rules

(d) Action to

be taken when sabotage is suspected

(e) Patrolling during emergencies

Related Topics