Chapter: Power Quality : Power Quality Monitoring

Monitoring Consideration - Power Quality Monitoring

MONITORING CONSIDERATION

The

monitoring objectives often determine the choice of monitoring equipment,

triggering thresholds, methods for data acquisition and storage, and analysis

and interpretation requirements. Several common objectives of power quality

monitoring are summarized here.

Monitoring to characterize system performance:

This is

the most general requirement. A power producer may find this objective

important if it has the need to understand its system performance and then

match that system performance with the needs of customers. System

characterization is a proactive approach to power quality monitoring. By

understanding the normal power quality performance of a system, a provider can

quickly identify problems and can offer information to its customers to help

them match their sensitive equipment’s characteristics with realistic power

quality characteristics.

Monitoring to characterize

specific problems:

Many

power quality service departments or plant managers solve problems by performing

short-term monitoring at specific customer sites or at difficult loads. This is

a reactive mode of power quality monitoring, but it frequently identifies the

cause of equipment incompatibility, which is the first step to a solution.

Monitoring as part of an enhanced

power quality service:

Many

power producers are currently considering additional services to offer

customers. One of these services would be to offer differentiated levels of

power quality to match the needs of specific customers. A provider and customer

can together achieve this goal by modifying the power system or by installing

equipment within the customer’s premises. In either case, monitoring becomes

essential to establish the benchmarks for the differentiated service and to

verify that the utility achieves contracted levels of power quality.

Monitoring as part of predictive

or just-in-time maintenance:

Power

quality data gathered over time can be analyzed to provide information relating

to specific equipment performance. For example, a repetitive arcing fault from

an underground cable may signify impending cable failure, or repetitive

capacitor-switching restrikes may signify impending failure on the

capacitor-switching device. Equipment maintenance can be quickly ordered to

avoid catastrophic failure, thus preventing major power quality disturbances

which ultimately will impact overall power quality performance.

The

monitoring program must be designed based on the appropriate objectives, and it

must make the information available in a convenient form and in a timely manner

(i.e., immediately). The most comprehensive monitoring approach will be a

permanently installed monitoring system with automatic collection of

information about steady-state power quality conditions and energy use as well

as disturbances.

1. Monitoring as part of a

facility site survey

Site

surveys are performed to evaluate concerns for power quality and equipment

performance throughout a facility. The survey will include inspection of wiring

and grounding concerns, equipment connections, and the voltage and current

characteristics throughout the facility. Power quality monitoring, along with

infrared scans and visual inspections, is an important part of the overall

survey. The initial site survey should be designed to obtain as much

information as possible about the customer facility. This information is

especially important when the monitoring objective is intended to address

specific power quality problems. This information is summarized here.

1. Nature of

the problems (data loss, nuisance trips, component failures, control system

malfunctions, etc.)

2. Characteristics

of the sensitive equipment experiencing problems (equipment design information

or at least application guide information)

3. The times

at which problems occur

4. Coincident

problems or known operations (e.g., capacitor switching) that occur at the same

time

5. Possible

sources of power quality variations within the facility (motor starting,

capacitor switching, power electronic equipment operation, arcing equipment,

etc.)

6. Existing

power conditioning equipment being used

7. Electrical

system data (one-line diagrams, transformer sizes and impedances, load

information, capacitor information, cable data, etc.)

2. Determining what to monitor

Power

quality encompasses a wide variety of conditions on the power system. Important

disturbances can range from very high frequency impulses caused by lightning

strokes or current chopping during circuit interruptions to long-term

overvoltages caused by a regulator tap switching problem. The range of

conditions that must be characterized creates challenges both in terms of the

monitoring equipment performance specifications and in the data-collection

requirements. The methods for characterizing the quality of ac power are

important for the monitoring requirements. For instance, characterizing most

transients requires high-frequency sampling of the actual waveform. Voltage

sags can be characterized with a plot of the rms voltage versus time. Outages

can be defined simply by a time duration. Monitoring to characterize harmonic

distortion levels and normal voltage variations requires steady-state sampling

with results analysis of trends over time. Extensive monitoring of all the

different types of power quality variations at many locations may be rather

costly in terms of hardware, communications charges, data management, and

report preparation. Hence, the priorities for monitoring should be determined

based on the objectives of the effort. Projects to benchmark system performance

should involve a reasonably complete monitoring effort. Projects designed to

evaluate compliance with IEEE Standard 519-1992 for harmonic distortion levels

may only require steady-state monitoring of harmonic levels. Other projects

focused on specific industrial problems may only require monitoring of rms

variations, such as voltage sags.

3. Choosing monitoring locations

Obviously,

we would like to monitor conditions at virtually all locations throughout the

system to completely understand the overall power quality. However, such

monitoring may be prohibitively expensive and there are challenges in data

management, analysis, and interpretation. Fortunately, taking measurements from

all possible locations is usually not necessary since measurements taken from

several strategic locations can be used to determine characteristics of the

overall system. Thus, it is very important that the monitoring locations be

selected carefully based on the monitoring objectives.

4. Options for permanent power

quality monitoring equipment

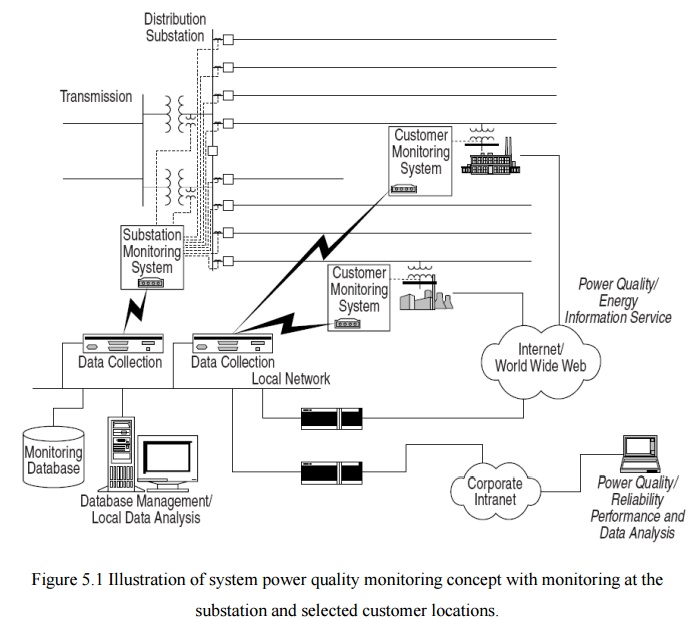

Permanent

power quality monitoring systems, such as the system illustrated in Fig. 5.1,

should take advantage of the wide variety of equipment that may have the

capability to record power quality information. Some of the categories of

equipment that can be incorporated into an overall monitoring system include

the following:

ü Digital fault recorders (DFRs). These may

already be in place at many substations.

DFR manufacturers do not design the devices specifically for power quality

monitoring. However, a DFR will typically trigger on fault events and record

the voltage and current waveforms that characterize the event. This makes them

valuable for characterizing rms disturbances, such as voltage sags, during

power system faults. DFRs also offer periodic waveform capture for calculating

harmonic distortion levels.

ü Smart relays and other IEDs. Many

types of substation equipment may have the

capability to be an intelligent electronic device (IED) with monitoring

capability. Manufacturers of devices like relays and re closers that monitor

the current anyway are adding on the capability to record disturbances and make

the information available to an overall monitoring system controller. These

devices can be located on the feeder circuits as well as at the substation.

ü Voltage recorders. Power

providers use a variety of voltage recorders to monitor steady-state voltage

variations on distribution systems. We are encountering more and more

sophisticated models fully capable of characterizing momentary voltage sags and

even harmonic distortion levels. Typically, the voltage recorder provides a

trend that gives the maximum, minimum, and average voltage within a specified

sampling window. With this type of sampling, the recorder can characterize a

voltage sag magnitude adequately. However, it will not provide the duration

with a resolution less than 2 s.

ü In-plant power monitors. It is now

common for monitoring systems in industrial

facilities to have some power quality capabilities. These monitors,

particularly those located at the service entrance, can be used as part of a

utility monitoring program. Capabilities usually include wave shape capture for

evaluation of harmonic distortion levels, voltage profiles for steady-state rms

variations, and triggered waveshape captures for voltage sag conditions. It is

not common for these instruments to have transient monitoring capabilities.

5. Finding the source of a

disturbance

The first

step in identifying the source of a disturbance is to correlate the disturbance

waveform with possible causes. Once a category for the cause has been

determined (e.g., load switching, capacitor switching, remote fault condition,

recloser operation), the identification becomes more straightforward. The

following general guidelines can help:

■ High-frequency voltage variations will be limited

to locations close to the source of the disturbance. Low-voltage (600 V and

below) wiring often damps out high-frequency components very quickly due to

circuit resistance, so these frequency components will only appear when the

monitor is located close to the source of the disturbance.

■ Power interruptions close to the monitoring

location will cause a very abrupt change in the voltage. Power interruptions

remote from the monitoring location will result in a decaying voltage due to

stored energy in rotating equipment and capacitors.

■ The highest harmonic voltage distortion levels

will occur close to capacitors that are causing resonance problems. In these

cases, a single frequency will usually dominate the voltage harmonic spectrum.

Related Topics